DOCUMENTAIRE JAPON "TOYOTA Valenciennes 1/3 : Le kaizen chez les ch'tis" (2001)

Summary

TLDRLe texte décrit l'arrivée de Toyota à Valenciennes, en France, et son impact sur la région avec la création de 15 100 emplois pour la production de la petite voiture Yaris. La région, autrefois touchée par le chômage, vit un renouveau d'espoir et de fierté. Les candidats à l'emploi afluent en nombre, passant par des tests écrits, des entretiens motivants et des simulations professionnelles pour intégrer l'entreprise. Le document souligne également la formation intensive des nouveaux employés, la culture de Toyota axée sur l'amélioration continue (kaizen) et l'importance de la communication ouverte dans la gestion japonaise.

Takeaways

- 🎉 La ville de Valenciennes célèbre l'arrivée de Toyota, le troisième plus grand constructeur automobile au monde, qui y construit une nouvelle usine pour produire la Yaris.

- 🏭 L'investissement de 4,5 milliards de francs apporte de l'espoir et de la fierté à une région touchée par le chômage, avec la création de 15 100 emplois.

- 📈 L'impact de l'arrivée de Toyota est immédiat, avec des milliers de candidatures spontanées reçues par l'ANPE pour les postes proposés.

- 📉 Le taux de chômage à Valenciennes est de 19%, ce qui représente un grand nombre de personnes à la recherche d'emploi, et l'arrivée de Toyota est vue comme une opportunité.

- 🔍 Le processus de recrutement de Toyota est rigoureux, nécessitant des tests écrits, des entretiens motivants et une simulation professionnelle pour sélectionner les candidats.

- 🌐 L'emplacement de la nouvelle usine à Valenciennes est stratégique, renforçant l'image de丰田 comme un employeur mondial et offrant des opportunités de carrière aux travailleurs locaux.

- 👷♂️ Les candidats sélectionnés passent par une formation intensive, y compris des stages au Japon, pour acquérir les valeurs et la philosophie de Toyota.

- 🛠️ La méthodologie de production Toyota, connue sous le nom de TPS (Toyota Production System), est axée sur la réduction des défauts et l'amélioration continue des processus.

- 📚 Les stagiaires apprennent l'importance de l'observation détaillée des mouvements et de la réflexion en équipe pour améliorer la qualité et l'efficacité.

- 🌟 Le succès de Toyota est attribué à son engagement envers la formation et le développement des employés, ainsi qu'à sa culture axée sur la qualité et la sécurité.

Q & A

Pourquoi Valenciennes est-elle célébrée dans le script?

-Valenciennes est célébrée car elle accueille une nouvelle usine de Toyota, qui apporte 15 100 emplois pour la production du Yaris, un petit véhicule urbain.

Quelle est la signification de l'arrivée de Toyota à Valenciennes pour la région?

-L'arrivée de Toyota à Valenciennes représente un espoir renouvelé et une fierté pour la région, offrant de nouveaux emplois et un avenir prometteur après des périodes d'affaiblissement économique.

Combien de candidatures Toyota a-t-elle reçues suite à l'annonce de la construction de la nouvelle usine?

-Toyota a reçu plus de quinze mille candidatures spontanées, environ 3 350 par semaine.

Quel est le taux de chômage à Valenciennes mentionné dans le script?

-Le taux de chômage à Valenciennes est légèrement supérieur à 19%.

Quels sont les emplois annoncés par Toyota pour la fin de l'année 2000?

-Toyota annonce 800 emplois pour la fin de l'année 2000, et après le recrutement d'une deuxième équipe, 1500 personnes seront recrutées au total.

Quels sont les critères de sélection de Toyota lors du recrutement?

-Toyota cherche des candidats avec un sens de l'initiative, des compétences et la volonté d'apprendre, plutôt que des diplômes.

Quel est le processus de sélection des candidats pour travailler à Toyota, comme décrit dans le script?

-Le processus comprend des tests écrits, des entretiens motivants, une journée de simulation professionnelle, y compris un test d'assemblage des jantes, une formation de trois mois, et un stage en France ou au Japon.

Quelle est la philosophie d'enseignement de Toyota mentionnée dans le script?

-La philosophie d'enseignement de Toyota est que tout individu peut accomplir n'importe quelle tâche, à condition d'être bien formé.

Quel est le système de production utilisé par Toyota, et quel est son objectif?

-Toyota utilise le système de production appelé TPS (Toyota Production System), qui vise à améliorer constamment les processus de production pour augmenter l'efficacité et la qualité.

Quelle est l'importance de la visite des candidats français dans les usines Toyota au Japon?

-La visite des usines au Japon permet aux candidats français de comprendre en détail le système de production Toyota, de vivre l'expérience et d'apporter cette connaissance dans la nouvelle usine en France.

Quelle est la signification du mot 'kaizen' dans le contexte de Toyota?

-Kaizen signifie 'amélioration continue' en japonais et est un principe clé des lignes de production Toyota, où chaque geste est observé pour détecter et éliminer les mouvements inutiles.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

DOCUMENTAIRE JAPON "Toyota Valenciennes 2/3 : Le Toyotisme en France" (2001)

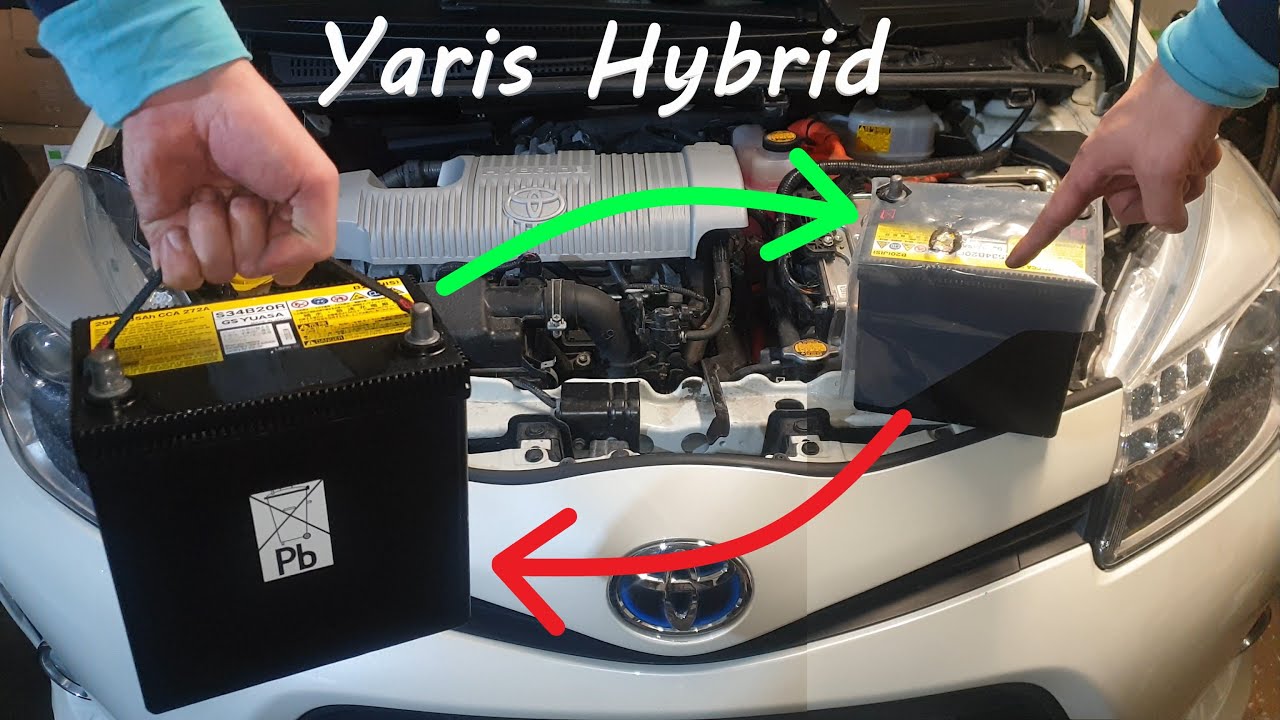

Toyota Yaris Hybrid 12v Battery Replacement

La P’tite Vadrouille - Saison 4 - Episode 5 - Le Boupère

Un territoire sous influence urbaine (Géographie 3e)

SEA-EU diversity - SPLIT - History

Episode 8 - de Mervent à Foussais-Payré

5.0 / 5 (0 votes)