Squirrel Cage Rotor and Slip Ring Rotor - Squirrel Cage vs Wound Rotor

Summary

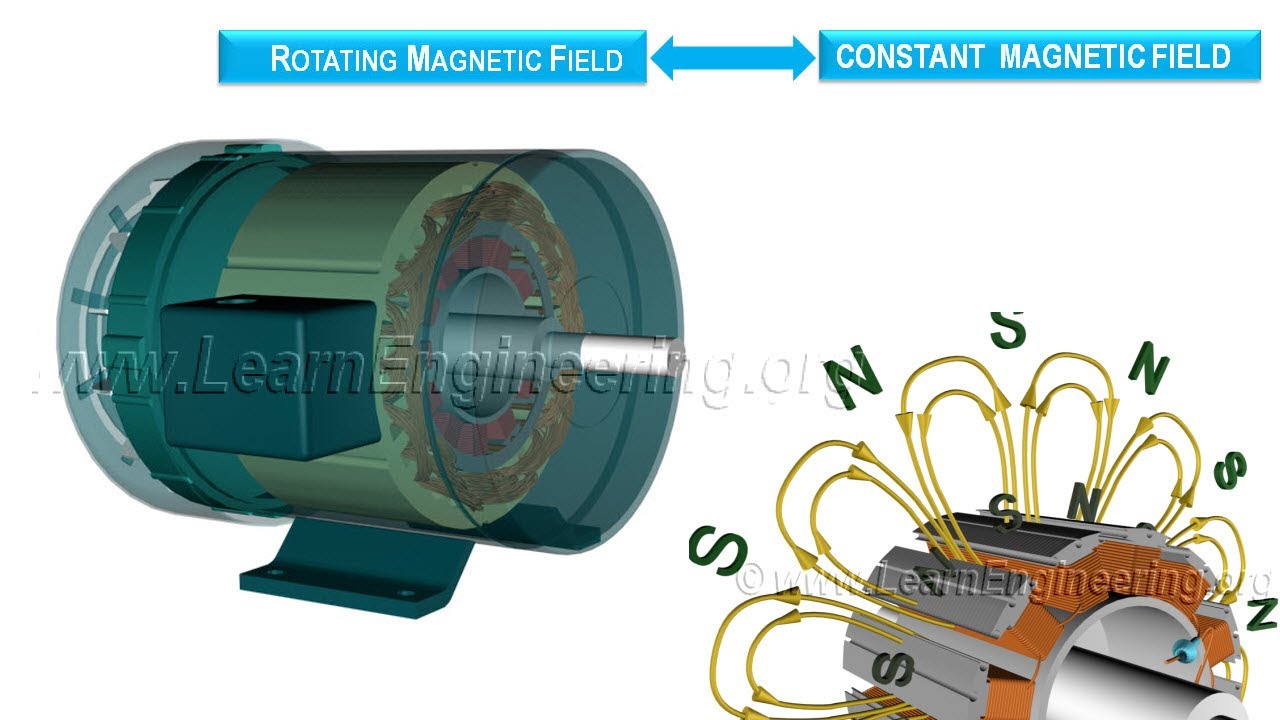

TLDRThis video explains the differences between slip ring and squirrel cage rotors in induction motors. The squirrel cage rotor is widely used in industries due to its low cost, robustness, efficiency, and minimal maintenance, while the slip ring rotor, used in only 5% of applications like lifts and cranes, allows for external resistance adjustment, offering high starting torque and speed control but requires frequent maintenance and is more expensive. The squirrel cage rotor, with its simple and durable construction, is prevalent in fans, blowers, and water pumps, providing moderate starting torque without speed control.

Takeaways

- 🐿️ The squirrel cage rotor is the most popular type of rotor in induction motors due to its affordability, robustness, efficiency, and reliability.

- 🔌 A wound-rotor, or slip ring rotor, allows for external resistance to be connected through slip rings, enabling speed or torque control.

- 🚫 Slip ring rotors have limited industrial applications compared to squirrel cage rotors.

- 🔌 Slip ring rotors feature three-phase windings similar to stators and can have external resistance added.

- 🏗️ Squirrel cage rotors consist of bars shorted at the ends with end rings, making them simple in construction.

- 💪 Slip ring rotors can achieve high starting torque, unlike squirrel cage rotors which have moderate and uncontrollable starting torque.

- 🛠️ Slip ring rotors have a more complex construction and require frequent maintenance due to the presence of slip rings and brushes.

- 🏭 Only 5% of induction motors in industry use slip ring rotors, while squirrel cage rotors dominate with 95% usage.

- 💰 Slip ring rotors are more costly and less efficient due to higher rotor copper loss, while squirrel cage rotors are cheaper and more efficient.

- 🏢 Slip ring rotors are used in applications like lifts, hoists, cranes, and elevators, whereas squirrel cage rotors are used in fans, blowers, and water pumps.

- 🔔 The video encourages viewers to like, share, and subscribe to the Learning Engineering channel for more updates.

Q & A

What is the most popular rotor type in induction motors?

-The squirrel cage rotor is the most popular rotor type in induction motors due to its low cost, robustness, efficiency, and reliability.

How are the windings of a wound-rotor induction motor connected to external resistance?

-In a wound-rotor induction motor, the rotor windings are connected to external resistance through slip rings.

What is the main advantage of adjusting the resistance in a wound-rotor induction motor?

-Adjusting the resistance allows for control over the motor's speed or torque characteristics.

Why is the slip ring rotor type less commonly used in industries compared to the squirrel cage rotor?

-The slip ring rotor has very little application in industries due to its complexity and the need for frequent maintenance.

What are the similarities between the slip ring type rotor and the stator winding?

-In the slip ring type rotor, there are three-phase windings similar to those found in the stator winding.

How does the construction of a squirrel cage rotor differ from that of a slip ring rotor?

-A squirrel cage rotor consists of bars shorted at the ends with end rings, whereas a slip ring rotor has a more complex construction with the presence of slip rings and brushes.

Why can't external resistance be added to a squirrel cage rotor?

-External resistance cannot be added to a squirrel cage rotor because the rotor is permanently shorted by the end rings.

What is the typical starting torque obtained in a squirrel cage rotor?

-A squirrel cage rotor typically obtains only moderate starting torque, which cannot be controlled.

What percentage of induction motors in the industry use slip ring type rotors?

-Only 5% of induction motors in the industry use slip ring type rotors.

How does the rotor construction in a slip ring type rotor affect maintenance requirements?

-The construction of a slip ring type rotor is delicate and requires frequent maintenance due to the presence of brushes.

Why are squirrel cage rotors considered more efficient than slip ring rotors?

-Squirrel cage rotors are more efficient because they have lower rotor copper losses compared to the higher losses in slip ring rotors.

In which applications are slip ring type rotors typically used?

-Slip ring type rotors are typically used in applications such as lifts, hoists, cranes, and elevators where speed control is necessary.

What types of applications are squirrel cage rotors commonly used for?

-Squirrel cage rotors are commonly used in applications like fans, blowers, and water pumps due to their simplicity and robustness.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

Slip ring Induction Motor, How it works?

Construction of Three Phase Induction Motor - Three Phase Induction Motor - Electrical Machines 3

How alternating current motors work?

LRS vs VFD| What is Liquid Resistance Starter| What is VFD| Function of VFD| Motor Starting Method

Working of Synchronous Motor

Induction Motor Construction (Squirrel Cage Rotor)

5.0 / 5 (0 votes)