What is the Difference Between PLC and DCS?

Summary

TLDRThis video delves into the history and evolution of PLCs (Programmable Logic Controllers) and DCSs (Distributed Control Systems), highlighting their differences and similarities. It explains how PLCs, initially designed for discrete controls, have become more sophisticated with advancements in technology, now rivaling DCSs in controlling complex processes. The script also discusses the advantages and disadvantages of each system, emphasizing that modern PLCs can perform tasks traditionally reserved for DCSs, while noting the specialized knowledge required for DCS programming.

Takeaways

- 👍 Engage with RealPars videos by liking, subscribing, and turning on notifications to stay updated.

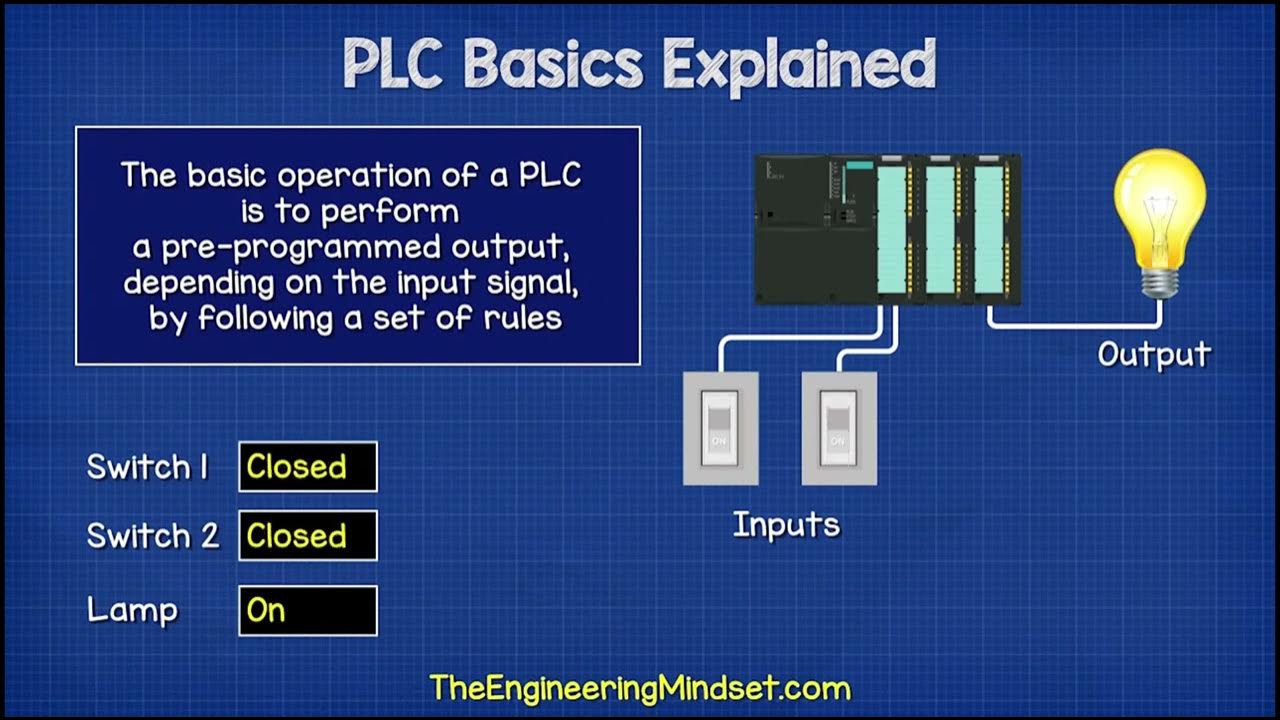

- 🤖 A PLC (Programmable Logic Controller) is a durable computer designed for process automation, differing from a DCS (Distributed Control System) which has multiple autonomous controllers.

- 🏂 The origin of the PLC can be traced back to Dick Morley, who sought a solution for repetitive tasks in the manufacturing industry and eventually founded Modicon.

- 📈 GM's large purchase of PLCs from Modicon marked a significant milestone in the adoption of PLC technology for replacing hard-wired relay systems.

- 🔄 The PLC was initially used for discrete controls and programmed primarily in ladder logic, which is similar to a schematic diagram.

- 🚀 The DCS emerged around 1975, leveraging the increasing use of microcomputers and offering benefits such as plant-wide connectivity and distributed control.

- 🛡️ DCS systems are robust due to their autonomous controllers, which allow for localized process control and minimize the impact of a single controller failure.

- 📊 DCS systems offer integrated monitoring and control similar to modern SCADA systems, utilizing the existing tag base for process control.

- 🔄 Function block programming in DCS systems simplifies code management by encapsulating complex operations behind a single interface.

- 🔌 Modern PLCs can now perform many of the same functions as DCS systems through open-source communications and networked autonomy.

- 💼 The choice between PLC and DCS systems today often comes down to factors such as installation costs, availability of skilled programmers, and specific system requirements.

Q & A

What is a PLC and how is it used in automation?

-A PLC, or programmable logic controller, is a ruggedized computer used for automating industrial processes. It was invented to perform repetitive tasks reliably and durably, primarily for discrete controls, and its programming is mainly done in ladder logic.

How does a DCS differ from a PLC?

-A DCS, or distributed control system, is similar to a PLC in that it uses rugged computer controllers, but it includes multiple autonomous controllers distributed throughout a system. This allows for more complex and scalable control of processes compared to a single PLC.

Who is credited with the creation of the first programmable controller?

-Dick Morley is credited with the creation of the first programmable controller. He drafted the idea during a hangover and later took it to his team at Bedford Associates, which eventually led to the creation of the company Modicon.

Why did GM contract with Modicon for PLCs?

-GM contracted with Modicon for PLCs because they needed a solid-state controller that would make plants more reliable and durable, replacing the hard-wired relay systems that were prevalent in the manufacturing industry at the time.

What was the significance of the PLC's introduction to the manufacturing industry?

-The introduction of the PLC to the manufacturing industry marked a significant shift towards automation and reliability. It allowed for the replacement of hard-wired relay systems with a more flexible, programmable solution that could handle repetitive tasks.

When did the concept of a DCS first emerge, and why?

-The concept of a DCS first emerged around 1975 due to the increasing use of microcomputers. It was developed to address the limitations of existing computer-based systems in terms of scalability, robustness, and security.

What are the benefits of using a DCS in a manufacturing plant?

-The benefits of using a DCS include the ability to connect an entire plant via proprietary communications, robustness due to distributed autonomous controllers that prevent plant-wide failure, and integrated monitoring and control systems similar to modern SCADA systems.

How has the evolution of technology affected the capabilities of PLCs and DCSs?

-The evolution of technology, including open-source communications, fiber optics, and Ethernet, has allowed PLCs to communicate with each other and function more autonomously. This has narrowed the gap between PLCs and DCSs in terms of controlling single or multiple processes within a plant.

What are some of the disadvantages of using a DCS compared to a PLC?

-Some disadvantages of using a DCS include higher installation costs due to the need for multiple controllers and the scarcity of programmers with DCS experience, as they typically require specialized knowledge in database functions and IT-related networking.

How do modern PLC systems compare to DCSs in terms of programming and control?

-Modern PLC systems can have nearly the same capabilities as DCSs, with the exception of supervisory control and data acquisition (SCADA). PLC systems may require additional development for monitoring and control systems, but they benefit from a larger pool of programmers and new programming languages that simplify development.

What is the primary factor to consider when choosing between a DCS and a PLC system for a plant?

-The primary factor to consider when choosing between a DCS and a PLC system is the specific needs and advantages of each system, including installation costs, the availability of skilled programmers, the required level of control and automation, and the overall system costs.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

When to use PLC ,DCS & SCADA | PLC vs DCS vs SCADA Selection Guide

Belajar PLC | Pengenalan Programmable Logic Controller #1

DCS vs PLC | Understanding the Differences and Applications

Electrical Review - PLC Basics Part 1

1. Berkenalan Dengan Kerja Perangkat Kontrol PLC

How to Interpret DCS and PLC Symbols on a P&ID

5.0 / 5 (0 votes)