DCS vs PLC | Understanding the Differences and Applications

Summary

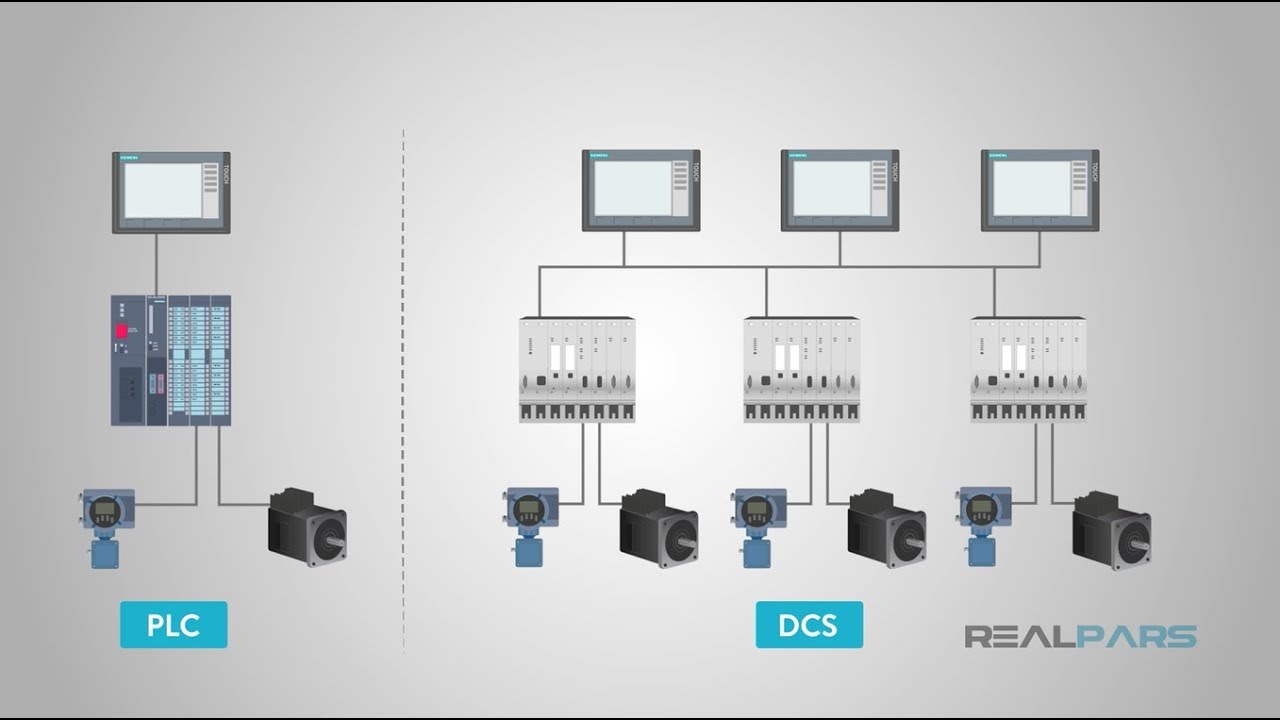

TLDRIn industrial automation, both PLC (Programmable Logic Controllers) and DCS (Distributed Control Systems) are essential in controlling complex processes, yet they differ significantly in their structure and use. PLCs are designed for controlling individual machines or processes, typically offering faster response times and lower costs, while DCS systems manage large networks and entire plants with greater flexibility and capability to handle large numbers of I/O points. This video explains these differences, covering their applications, capabilities, response times, and architectural distinctions, providing a clear understanding of when and why each system is used.

Takeaways

- 😀 PLC (Programmable Logic Controller) is designed to control individual machines or processes.

- 😀 DCS (Distributed Control System) is designed to control entire plants, buildings, or processes over a large network.

- 😀 PLC can handle tens or hundreds of digital I/Os and a limited number of analog I/Os, while DCS can manage hundreds of thousands of digital I/Os and thousands of analog I/Os.

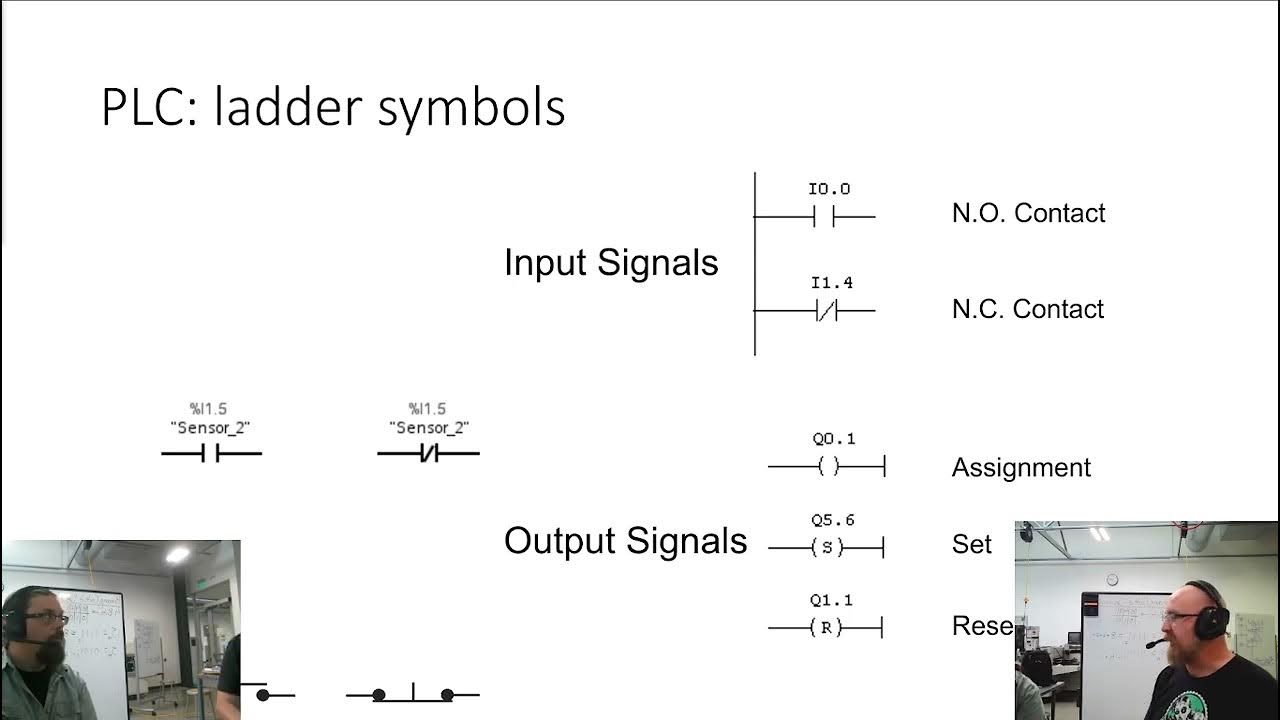

- 😀 PLC is commonly programmed using ladder logic, while DCS comes with built-in control functions that need to be configured for various applications.

- 😀 PLC systems have a faster response time, typically one-tenth of a second, compared to DCS's typical response time of 30 milliseconds.

- 😀 PLC has a simple and flexible architecture, consisting of CPU, I/O modules, expansion modules, HMIs, and engineering software.

- 😀 DCS systems are less flexible than PLCs, as they involve multiple controllers, I/O systems, database servers, engineering servers, and operating servers.

- 😀 PLCs are typically used for controlling machines like a lathe machine, while DCS is used for controlling complete processes, like those in a car manufacturing plant.

- 😀 The cost of a PLC is generally lower than that of a DCS.

- 😀 PLCs are ideal for smaller-scale control applications, while DCS is better suited for large-scale, complex process control environments.

- 😀 The main difference between PLC and DCS is their scalability, with PLCs being more suited to individual machine control, and DCS designed for broader, large-scale system integration.

Q & A

What is the primary role of PLC and DCS in industrial automation?

-Both PLC (Programmable Logic Controller) and DCS (Distributed Control Systems) play essential roles in managing and controlling complex processes in industrial automation, but they differ in architecture, applications, and capabilities.

How do the architectures of PLC and DCS differ?

-PLC is a single entity designed to control individual machines or processes, while DCS is a distributed system designed to control entire plants or processes across a large network.

How does the I/O capability of PLC compare to DCS?

-PLC can handle tens to hundreds of digital inputs and outputs (IOs) and a few tens of analog IOs. In contrast, DCS can support hundreds of thousands of digital IOs and thousands of analog IOs.

What type of programming language is typically used for PLC?

-PLC is typically programmed using ladder logic, which is customized based on the specific application.

How does the response time of PLC compare to DCS?

-PLC has a faster response time of about one-tenth of a second, whereas DCS has a response time of around 30 milliseconds, making it slower than PLC.

What are the basic components of a PLC system?

-A PLC system generally consists of a CPU, I/O modules, expansion modules, HMIs (Human-Machine Interfaces), and engineering software.

What makes DCS systems less flexible compared to PLCs?

-DCS systems are less flexible because they are more complex, incorporating multiple controllers, I/O systems, database servers, engineering servers, and operating servers.

What types of applications are PLCs typically used for?

-PLCs are designed for controlling individual machines, such as a lathe machine, where it manages the operation of a single machine.

How does DCS manage larger processes compared to PLC?

-DCS is designed to control entire processes, such as a car manufacturing factory, where it manages multiple machine operations spread across various locations.

Which is more cost-effective, PLC or DCS?

-PLCs are generally cheaper than DCS due to their simpler architecture and more focused application.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

What is the Difference Between PLC and DCS?

SysAp 7 1 Ladder Logic

DISTRIBUTE CONTROL SYSTEM (DCS) SISTEM KONTROL TERDISTRIBUSI - DALAM OTOMASI INDUSTRI

When to use PLC ,DCS & SCADA | PLC vs DCS vs SCADA Selection Guide

What is DCS? (Distributed Control System)

AWAL BELAJAR Ngobrol Santai Tentang PLC (Programmable Logic Controller)

5.0 / 5 (0 votes)