Fundamental of Pipe (Pipeline) for Oil & Gas Engineer - Revised

Summary

TLDRIn this video, Varun Patel introduces the fundamentals of process piping in the oil and gas industry. He covers key topics such as different types of pipes, materials, ASTM grades, and the significance of NPS (Nominal Pipe Size) and Schedule numbers. The video explores pipe length classifications, including single and double random lengths, and delves into the differences between small bore and large bore pipes. It also provides insight into pipe thickness, including schedule numbers and the importance of understanding pipe sizes, thickness, and end types for efficient piping systems.

Takeaways

- 😀 Pipes in the oil and gas industry are classified into seamless and welded categories, with different welding methods including SAW, ERW, and HFW.

- 😀 ASME B31.3 outlines various materials for process piping, such as carbon steel, stainless steel, titanium, PVC, and HDPE, each for specific temperature and corrosive conditions.

- 😀 Lined and claded pipes combine two materials to provide cost-effective solutions, such as using carbon steel for strength and stainless steel for corrosion resistance.

- 😀 Pipe size is defined using NPS (Nominal Pipe Size), which is a standardized measurement that differs from the actual pipe's inner or outer diameter.

- 😀 NPS, NB, and ND are terms used globally to define pipe sizes, with NPS being the American standard and NB/ND used in Europe and Germany respectively.

- 😀 Small bore pipes are typically those with a size range of ½” to 1 ½”, while large bore pipes are those with sizes starting at 2” and above.

- 😀 Standard dimensions for carbon and alloy steel pipes are defined in ASME B36.10, while stainless steel pipes are defined in ASME B36.19.

- 😀 Pipes are manufactured in specific lengths such as single random (4.8m to 6.7m) and double random (10.7m and above) based on construction requirements.

- 😀 The pipe schedule number (e.g., 5, 10, 20, 40) indicates the thickness of the pipe, with higher schedule numbers corresponding to thicker pipes and smaller inner diameters.

- 😀 Schedule number is calculated using the formula: 1000 * P / S, where P is the service pressure and S is the allowable stress, determining pipe thickness for safety in the system.

Q & A

What is the primary purpose of pipes in the oil and gas industry?

-Pipes are used in the piping system to transport liquids, gases, and sometimes solids in the oil and gas industry. They are essential for transferring fluids between various parts of a plant or facility.

What are the two main categories of pipes used in process piping?

-The two main categories of pipes used in process piping are seamless pipes and welded pipes.

How are welded pipes classified?

-Welded pipes are classified based on the welding method used. There are two types: welding with filler metal (SAW process) and welding without filler metal (ERW and HFW processes).

What is the difference between lined and cladded pipes?

-Lined pipes have a mechanical bond between the pipe and the liner material, offering benefits such as anti-corrosion properties. Cladded pipes, on the other hand, have a metallurgical bond, often achieved by explosive bonding or welding, combining high-strength carbon steel with corrosion-resistant materials.

What is the difference between NPS, NB, and DN when referring to pipe sizes?

-NPS (Nominal Pipe Size) is used in American standards, NB (Nominal Bore) is the European equivalent, and DN (Diameter Nominal) is the German equivalent. All these terms define pipe size, but NPS is commonly used in the United States while NB and DN are used in Europe and Germany, respectively.

What are small bore and large bore pipes?

-Small bore pipes are typically those with sizes ranging from ½” to 1 ½”, while large bore pipes are generally those with sizes of 2” and above. This classification may vary slightly by company.

How are pipe lengths categorized in the process industry?

-Pipe lengths are categorized into single random and double random. Single random pipes typically range from 4.8 meters to 6.7 meters, while double random pipes have a minimum average length of 10.7 meters, with lengths ranging from 4.8 meters to 10.7 meters.

What does the schedule number of a pipe refer to?

-The schedule number of a pipe indicates its thickness. The higher the schedule number, the thicker the pipe wall and the smaller the inside diameter. Schedule numbers like 5, 10, 20, 30, and 40 are commonly used.

What does the equation for the schedule number, S = 1000P/S, represent?

-The equation for the schedule number, where P is the service pressure and S is the allowable stress, helps determine the appropriate pipe thickness for a given application. The higher the service pressure, the higher the schedule number.

What are the different types of pipe ends used in piping systems?

-Pipes can have plain ends, beveled ends, threaded ends, or special ends. Plain ends are used with socket-type weld fittings, beveled ends are for butt-weld fittings, threaded ends are used for threaded connections, and special ends like socket & spigot with O-ring gaskets are also available.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

Seamless Pipe Manufacturing Processes – Explained

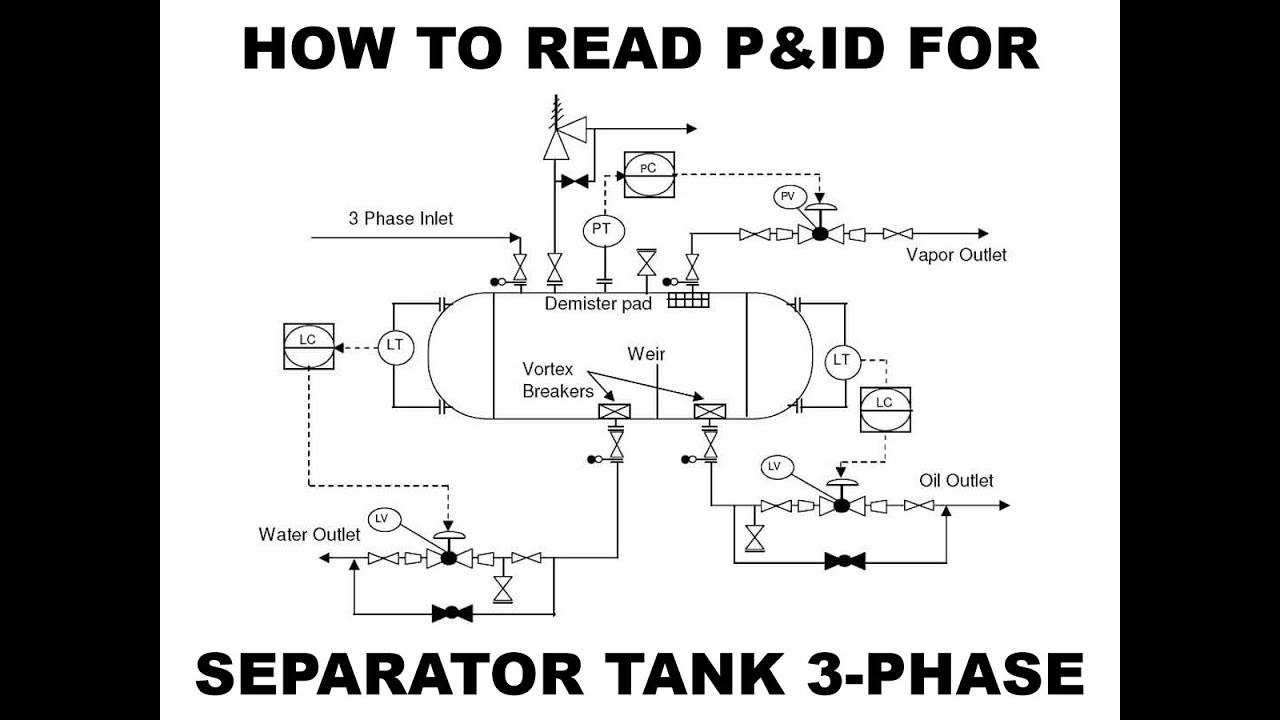

How To Read P&ID Diagram for Separator Tank (3-Phase) in Malay - Nazmi Ismail

Understanding Piping Materials:A53 vs A106, SS304 vs SS316|| difference between piping materials

Pipe Manufacturing Process for Welded Pipe (SAW & ERW)

Pipe Rack Design Project Overview

How Oil and Gas are Formed and Trapped Underground | Petroleum Geology Explained

5.0 / 5 (0 votes)