Seamless Pipe Manufacturing Processes – Explained

Summary

TLDRIn this video, Varun Patel explains the seamless pipe manufacturing process, covering methods such as the Mandrel Mill, Mannesmann Plug Mill, Forging, and Extrusion processes. He walks through each method, detailing how steel billets are transformed into pipes with varying thickness and dimensions. The video also highlights essential quality tests, including NDT inspections, hydro tests, and dimensional checks, ensuring the final product meets required standards. Additionally, Varun introduces various heat treatment processes and invites viewers to subscribe for regular updates and free resources on piping components.

Takeaways

- 😀 Mandrel Mill Process: A steel billet is heated and shaped into a cylindrical hollow (mother hollow) using a rotary piercer and roller arrangement.

- 😀 The outside diameter of the pipe is achieved with the help of secondary rollers, known as the MPM (Multistand Pipe Mill), after the mother hollow is created.

- 😀 After the pipe is formed, it's reheated to maintain temperature, then sent for scratch reduction to improve its surface finish and dimensions.

- 😀 The finished pipes are cooled, cut to size, straightened, and undergo various non-destructive testing (NDT) methods, such as eddy current and ultrasonic inspections.

- 😀 Pipes are hydro tested to ensure leak-proof strength under pressure and then visually and dimensionally inspected before being marked and packaged.

- 😀 Mannesmann Plug Mill Process: Unlike the Mandrel Mill, the Mannesmann process allows for multi-stage reduction, achieving greater thickness reduction.

- 😀 The Mannesmann process is ideal for producing stainless steel, low alloy steel, and thick carbon steel pipes, which are subjected to various heat treatments like normalizing, quenching, and tempering.

- 😀 Forging Process: A heated billet is placed into a forging die and shaped using a hydraulic press or forging hammer to create large diameter pipes, typically used for steam headers and pressure vessels.

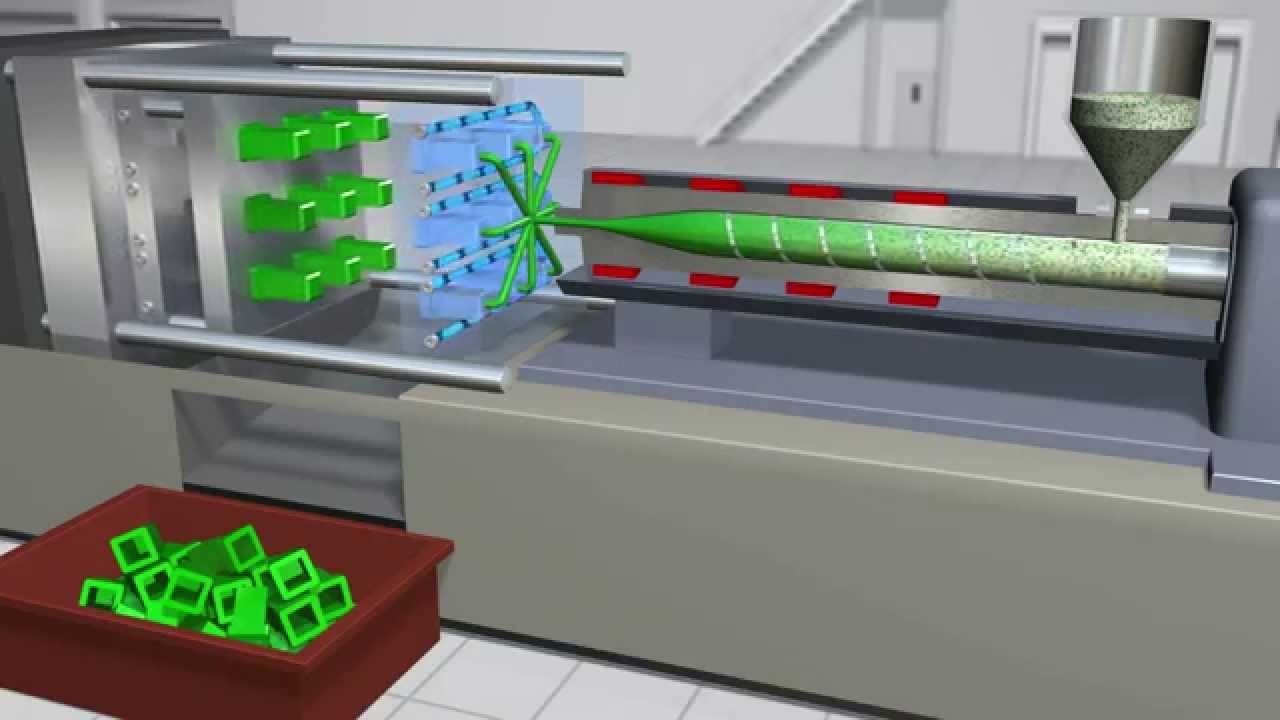

- 😀 The extrusion process involves a heated billet being pushed through a die with a hydraulic ram, creating a pipe by forcing material through a cylindrical cavity.

- 😀 Extrusion is useful for producing pipes with high thickness (mother hollow), from which various secondary pipes can be manufactured with different dimensions.

Q & A

What is the Mandrel Mill Process in seamless pipe manufacturing?

-The Mandrel Mill Process involves heating a steel billet to a forging temperature in a rotary furnace. A cylindrical hollow, known as the mother hollow, is produced with the help of a rotary piercer and roller arrangement. The outside diameter is controlled, and the pipe is then further processed to achieve the desired dimensions and surface finish.

How is temperature maintained during the Mandrel Mill Process?

-After the initial stages of the Mandrel Mill Process, the pipe is sent to a reheating furnace to increase its temperature, ensuring that the pipe remains malleable and can undergo further processing without losing its shape.

What happens after the pipe has been reheated in the Mandrel Mill Process?

-After reheating, the pipe is sent for scratch reducing, where the dimensions and surface finish are improved. The temperature is then reduced to atmospheric conditions on a cooling bed before it is cut to size and sent for straightening.

What types of non-destructive testing (NDT) are done on the pipes?

-The pipes undergo various NDT inspections, such as eddy current and ultrasonic testing, to ensure the structural integrity of the pipe. If the pipes pass these tests, they are then subjected to a hydrostatic test to ensure they can withstand pressure without leaking.

What is the Mannesmann Plug Mill Process?

-The Mannesmann Plug Mill Process, invented by German engineer Mannesmann, allows multi-stage reduction of pipe thickness. Unlike the Mandrel Mill Process, which achieves the inside diameter in a single pass, the Mannesmann process offers greater thickness reduction and is suitable for higher thickness pipes.

What is the role of heat treatment in pipe manufacturing?

-In seamless pipe manufacturing, heat treatment is essential for improving the mechanical properties of the pipe. Common treatments include normalizing, quenching, tempering, solution annealing, and stress relieving, depending on the material and the intended application of the pipe.

Why is the forging process used in seamless pipe manufacturing?

-The forging process is used to manufacture large diameter seamless pipes that cannot be produced by traditional methods. In this process, a heated billet is placed in a forging die and shaped using a hydraulic press or hammer. These forged pipes are often used in high-pressure applications such as steam headers and pressure vessel shells.

How does the extrusion process differ from other methods in seamless pipe manufacturing?

-In the extrusion process, a heated billet is pushed through a die by a hydraulic ram, and the material flows to form the pipe. This process can create pipes with larger thickness, known as the mother hollow, which can then be further processed to produce pipes of different dimensions.

What is a mother hollow in the extrusion process?

-A mother hollow is a pipe with a high thickness produced in the extrusion process. It serves as a base material for producing secondary pipes of different dimensions by using additional processing steps.

What is the significance of NDT and hydro testing in pipe manufacturing?

-NDT and hydro testing are crucial steps in ensuring the quality and safety of the pipes. NDT checks for any internal or surface defects, while hydro testing ensures that the pipe can withstand internal pressure without leaking. These tests confirm that the pipe meets the required standards and specifications.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Pipe Manufacturing Process for Welded Pipe (SAW & ERW)

Fundamental of Pipe (Pipeline) for Oil & Gas Engineer - Revised

Pipe Inspection and Testing requirements.

Plastic Processing Overview

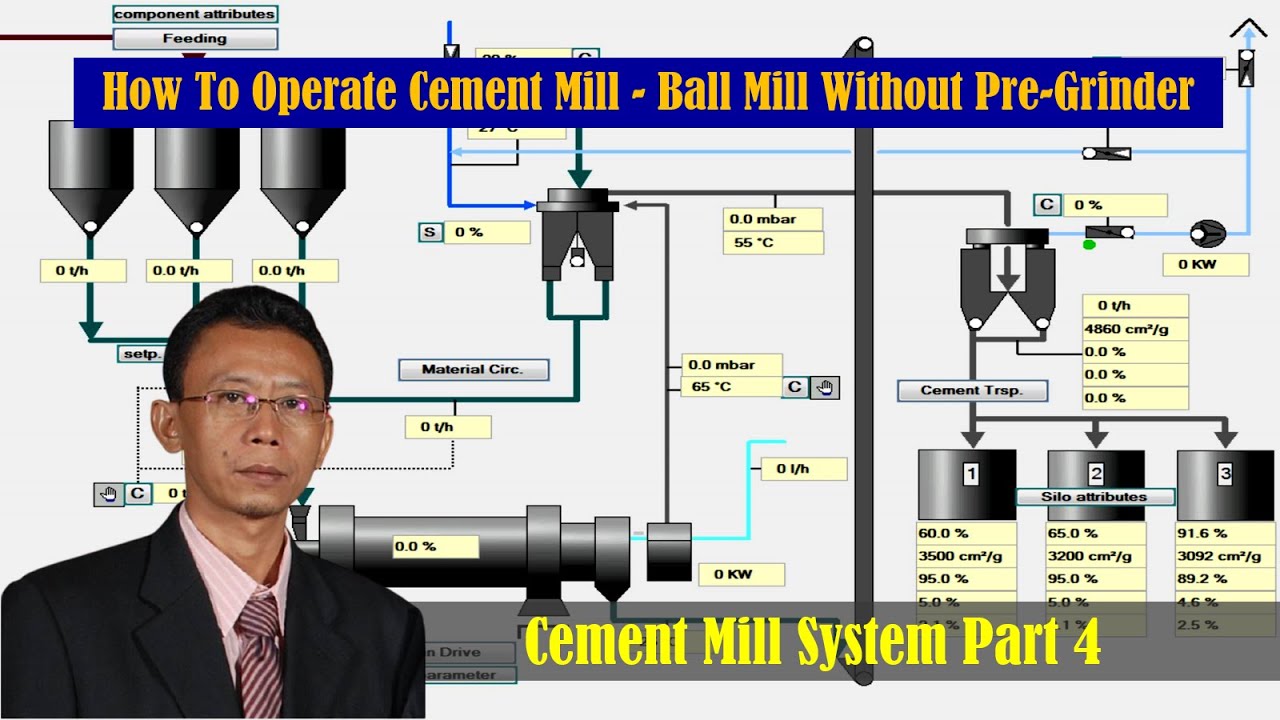

Cement Milling Process Ball Mill Operation Using Simulator _ English Version

Materiais e Processos de Fabricação para Engenharia de Produção - Processo de forjamento

5.0 / 5 (0 votes)