Ternyata Begini Proses pengolahan tebu menjadi gula pasir Dari Awal Hingga Akhir

Summary

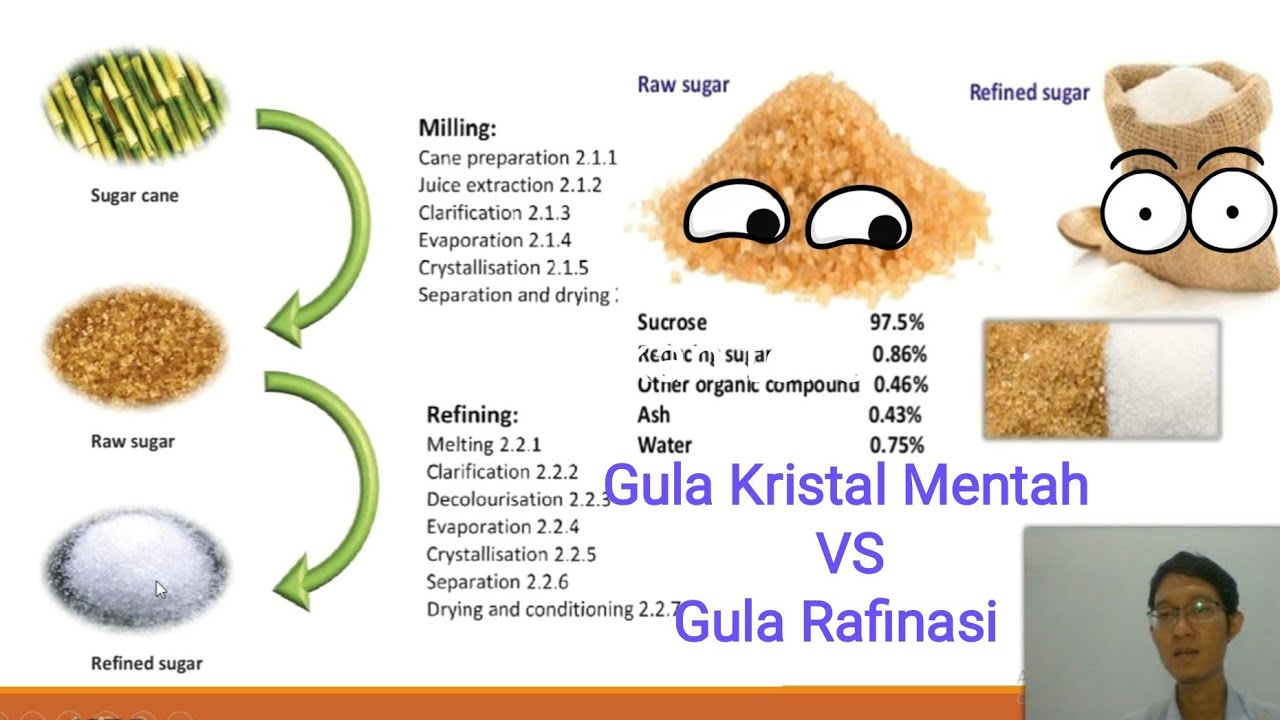

TLDRThis video provides an in-depth exploration of sugar production in Indonesia, highlighting the historical significance and modern processes involved in turning sugar cane into refined sugar. It explains the cultivation of sugar cane primarily in Java, the meticulous steps of sorting, grinding, juice extraction, purification, evaporation, and crystallization. The video also emphasizes the role of sugar mills, some of which have been operating since the Dutch colonial period, and how these mills are essential to meeting the national sugar demand. This comprehensive overview offers insights into the importance of sugar in daily life and its production methods.

Takeaways

- 😀 The production of sugar from sugarcane has been ongoing for decades in Indonesia, with some factories still operating since the Dutch colonial era.

- 😀 Sugar is an essential food ingredient used mainly as a natural sweetener, alongside honey, and is crucial in human life.

- 😀 Sugarcane is a primary source of sugar and is predominantly grown in the provinces of Yogyakarta, Central Java, and East Java in Indonesia.

- 😀 The harvesting and processing of sugarcane follow a contract system, from land preparation to planting, harvesting, and selling the crops.

- 😀 Once sugarcane is harvested, it must be processed immediately at the nearby sugar mills to preserve the quality and quantity of sugar produced.

- 😀 The sugarcane is first sorted to meet specific criteria before it is processed into sugar, including being ripe, clean, and fresh.

- 😀 The primary process in sugar production is the extraction of juice (known as Nira) from sugarcane by grinding, which is done several times for maximum extraction.

- 😀 The Nira extracted from the sugarcane may contain impurities like dirt or skin, which are removed during the purification process to ensure quality sugar.

- 😀 After purification, the Nira is concentrated through evaporation at controlled temperatures to facilitate the crystallization process.

- 😀 The crystallization process separates the sugar crystals from remaining impurities, and the quality of sugar is classified based on purity levels.

- 😀 The sugar crystals undergo a final separation in a spinning process to remove syrup that may still be attached to them.

Q & A

What is the primary raw material used to produce sugar in Indonesia?

-The primary raw material used to produce sugar in Indonesia is sugarcane, which is widely grown in regions like Yogyakarta, Central Java, and East Java.

Why is it important to process sugarcane quickly after harvesting?

-It is important to process sugarcane quickly after harvesting because if left too long, the water and glucose content in the cane will decrease, negatively affecting the quantity and quality of the sugar produced.

What is the first step in the sugar production process after the sugarcane is harvested?

-The first step in the sugar production process is sorting the sugarcane to ensure it meets the necessary criteria, such as being mature, clean, and fresh, before it is sent to the sugar mill for processing.

How many times is the sugarcane typically milled during the extraction of Nira (sugarcane juice)?

-Sugarcane is typically milled up to 10 times to extract as much Nira (sugarcane juice) as possible.

What is Nira, and why is it important in sugar production?

-Nira is the juice extracted from sugarcane during the milling process. It is crucial because it contains the sugar that will later be processed into crystallized sugar.

What methods are used to purify the Nira during the sugar production process?

-The Nira is purified using methods such as defecation, sulfitation, flotation, sedimentation, filtration, or by using chemicals to separate non-sugar components.

What happens to the Nira after it has been purified in the sugar production process?

-Once the Nira is purified, it is transferred to the evaporation stage, where it is thickened to facilitate the crystallization of sugar.

At what temperature is the Nira evaporated during the sugar production process?

-The Nira is evaporated at a temperature range of 65 to 70 degrees Celsius to avoid damaging the sugar.

What is the purpose of the crystallization step in sugar production?

-The purpose of crystallization is to separate the sugar crystals from any remaining impurities and to sort the crystals by purity levels.

What happens to the sugar crystals after they are formed in the crystallization process?

-After crystallization, the sugar crystals go through a spinning process to separate them from the syrup or molasses that may still be attached to them.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

How Modern Factory Producing Crystal Sugar Efficiently?

TERNYATA BEGINI PROSES PEMBUATAN GULA PASIR EROPA BERBAHAN DARI UMBI SUGAR BEET

Sering Dikonsumsi, Tapi Ga Tau Prosessnya? Begini Cara Kerja Mesin Gula Pasir Dari Awal Hingga Akhir

Ekstraksi Tebu menjadi Nira - Diagram Alir Proses Industri Gula (part 1/4)

Growing and Harvesting Billions Tons of Sugarcane to make Sugar - Sugar Processing Line in Factory

How It's Made: Sugar

5.0 / 5 (0 votes)