Ekstraksi Tebu menjadi Nira - Diagram Alir Proses Industri Gula (part 1/4)

Summary

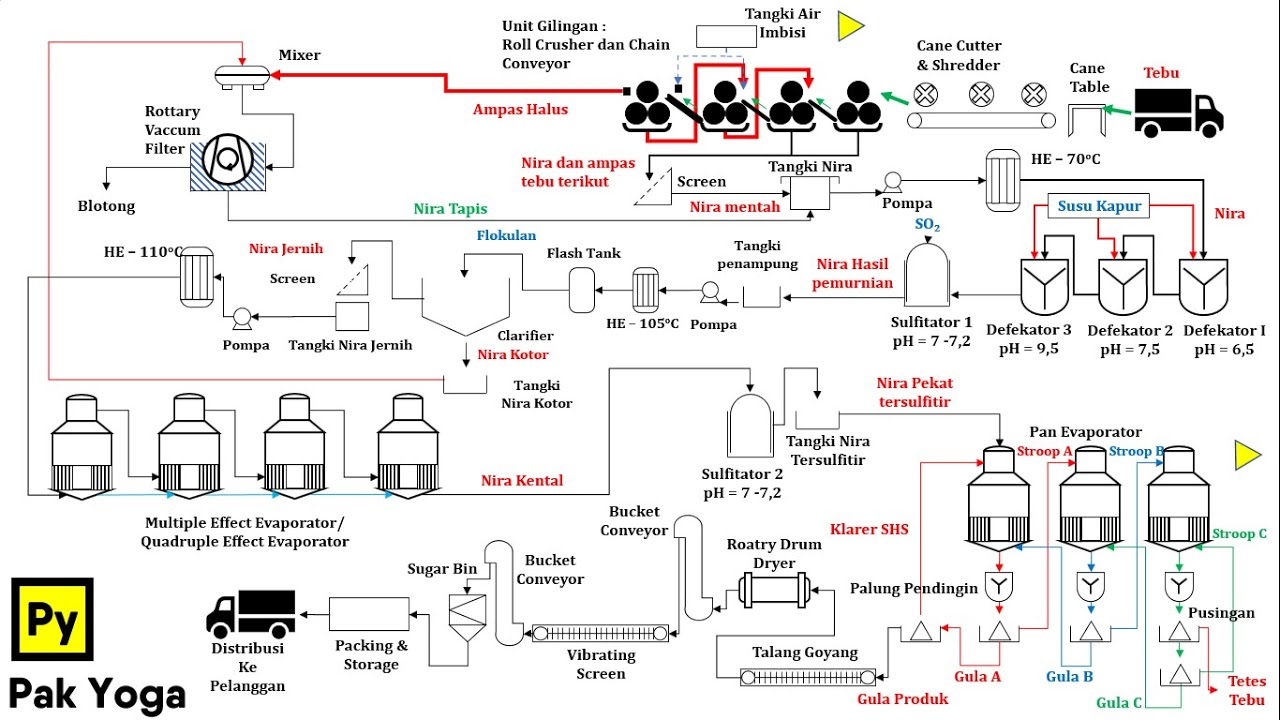

TLDRThis video explains the sugar production process from sugarcane in Indonesia, focusing on raw and refined sugars. It outlines the steps involved in sugar extraction and refining, from harvesting and milling to the purification stages like evaporation, crystallization, and drying. The video highlights key equipment such as conveyors and roll mills used in the extraction process. Additionally, it covers byproducts like molasses and bagasse, as well as the factors influencing sugar yield, such as the age of the sugarcane and harvesting conditions. The video provides valuable insights into both the main and secondary products of sugarcane processing.

Takeaways

- 😀 The video discusses the production process of sugar from sugarcane, focusing on the differences between raw sugar (unrefined) and refined sugar (refined).

- 😀 Raw sugar has a brown color and is less processed, while refined sugar is white and contains about 97.5% sucrose.

- 😀 The process begins with the milling or crushing of sugarcane to extract juice, followed by refining to produce refined sugar.

- 😀 The stages of sugar production include preparation, extraction, clarification, evaporation, crystallization, separation, and drying.

- 😀 Key terms like 'Nira' (sugarcane juice), 'Bagasse' (cane residue), and 'Molasses' (by-product) are introduced during the sugar production process.

- 😀 The first stage of the process involves cutting and transporting sugarcane, followed by preparation for grinding, which is essential for efficiency.

- 😀 The extraction stage uses mechanical rollers to squeeze the juice out of shredded sugarcane, and warm water is added to help dissolve the sugar.

- 😀 After extraction, the juice goes through clarification and evaporation stages, concentrating the sugar solution into syrup.

- 😀 Crystallization is the process where the sugar syrup is turned into solid sugar crystals, which are then separated and dried.

- 😀 The video also discusses the importance of 'rendemen,' which refers to the yield of sugar extracted from sugarcane, influenced by factors like age, weather, and harvest time.

Q & A

What are the two main types of sugar produced from sugarcane?

-The two main types of sugar produced from sugarcane are raw sugar (or 'troll sugar') and refined sugar.

What is the difference between raw sugar and refined sugar?

-Raw sugar is brown in color, while refined sugar is white. Refined sugar has a higher sucrose content (97.5%) and undergoes further processing to remove impurities.

What is the role of clarification in the sugar production process?

-Clarification is the process of purifying the juice extracted from sugarcane (known as Nira) by removing impurities through sedimentation.

What is the purpose of evaporation in the sugar production process?

-Evaporation is used to concentrate the juice (Nira) by removing excess water, making it more suitable for crystallization.

What happens during crystallization in sugar production?

-During crystallization, the concentrated juice is transformed into sugar crystals through cooling and the addition of specific conditions that promote crystallization.

What is the function of a centrifugal machine in the sugar production process?

-A centrifugal machine is used to separate the sugar crystals from the remaining liquid after crystallization, helping to purify the sugar.

What is molasses, and how is it related to sugar production?

-Molasses is a by-product of sugar production, which is the leftover syrup after most of the sugar crystals have been extracted. It can be used to produce other products.

What is bagasse, and how is it used in the sugar industry?

-Bagasse is the fibrous residue left after extracting juice from sugarcane. It is often used as a fuel in boilers to generate electricity for the sugar factory.

How does the quality of sugarcane affect the yield of sugar?

-The quality of sugarcane, such as its age and weight, affects the yield of sugar. Older and heavier sugarcane tends to produce more sugar, increasing the overall rendement (sugar yield).

What are the factors that influence the rendement (sugar yield) in sugar production?

-Factors influencing rendement include the age of the sugarcane, the harvest period (with dry seasons providing higher yields), the efficiency of the milling process, and the effectiveness of purification methods like defecation and carbonatation.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Sering Dikonsumsi, Tapi Ga Tau Prosessnya? Begini Cara Kerja Mesin Gula Pasir Dari Awal Hingga Akhir

THIS IS THE MODERN PROCESS OF SUGAR FARMING IN AUSTRALIA | THE SECRET BEHIND EXPORTED GRANULATED ...

How Modern Factory Producing Crystal Sugar Efficiently?

Kimia Industri - Diagram Alir Proses Pembuatan Gula tebu

Growing and Harvesting Billions Tons of Sugarcane to make Sugar - Sugar Processing Line in Factory

Pabrik Pembuatan Gula Pasir | SI UNYIL (17/03/20) PART 1

5.0 / 5 (0 votes)