Sistemas auxiliares – Sistema de alimentação - Ar

Summary

TLDRThis video explains the key components of air intake and fuel supply systems in agricultural machinery. It covers the function of air filters, including pre-filters and main filters, as well as how naturally aspirated and turbocharged engines differ in air intake. The video also discusses the role of intercoolers in cooling compressed air and enhancing engine performance. Additionally, the fuel supply system is briefly outlined. Through these insights, the video demonstrates how these systems work together to improve engine efficiency and power in farming equipment, ensuring optimal performance in demanding agricultural environments.

Takeaways

- 😀 The air intake system in agricultural machinery is crucial for engine performance, supplying both air and fuel to the engine.

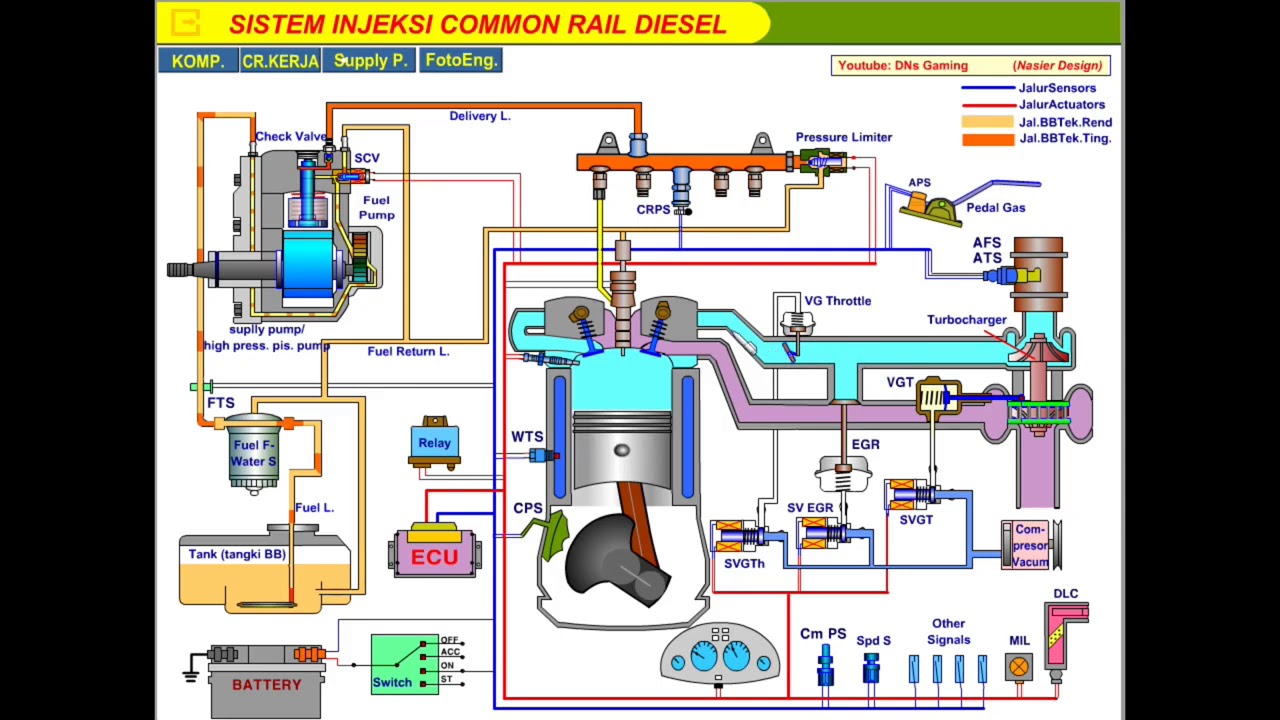

- 😀 The air intake system includes multiple components like filters, pre-filters, intercoolers, and valves, each playing a vital role in air filtration and pressure regulation.

- 😀 Pre-filters, often used in agricultural machinery, help trap larger particles of dust and debris, especially in environments with high levels of dust during operations like planting and harvesting.

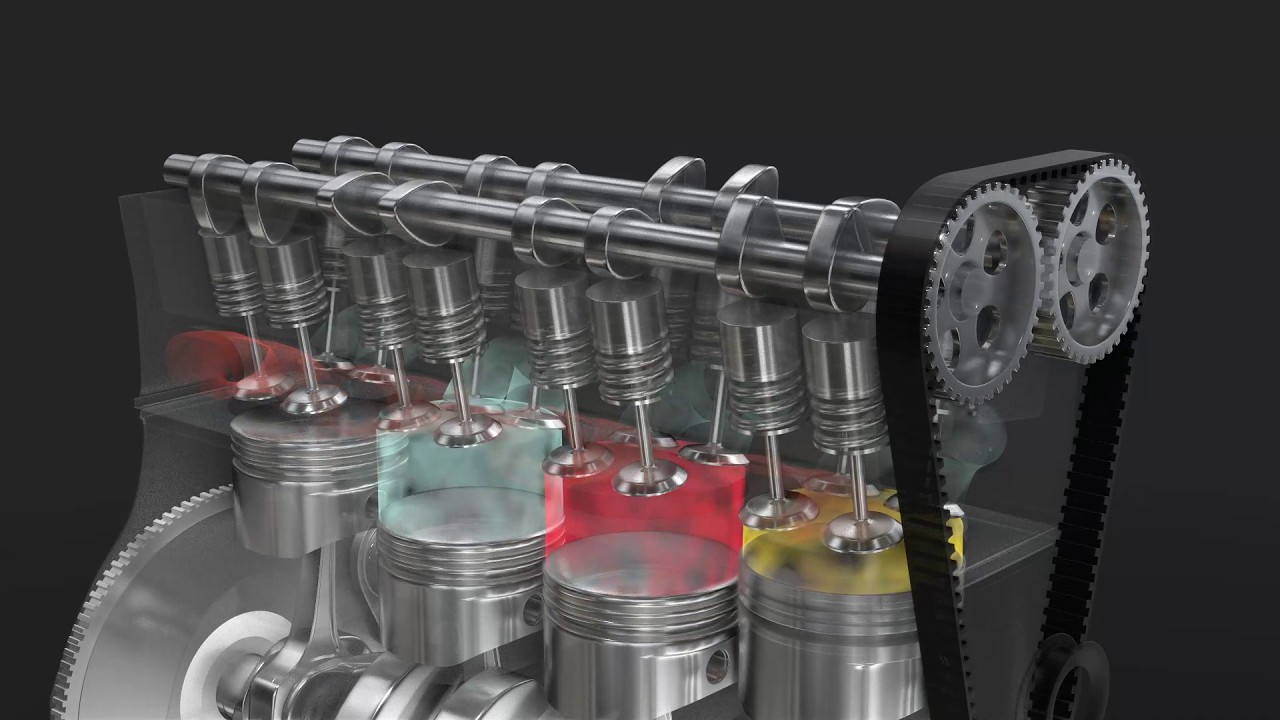

- 😀 The main filter, typically a paper or oil bath filter, removes smaller impurities from the air before it enters the engine, ensuring cleaner air for better combustion.

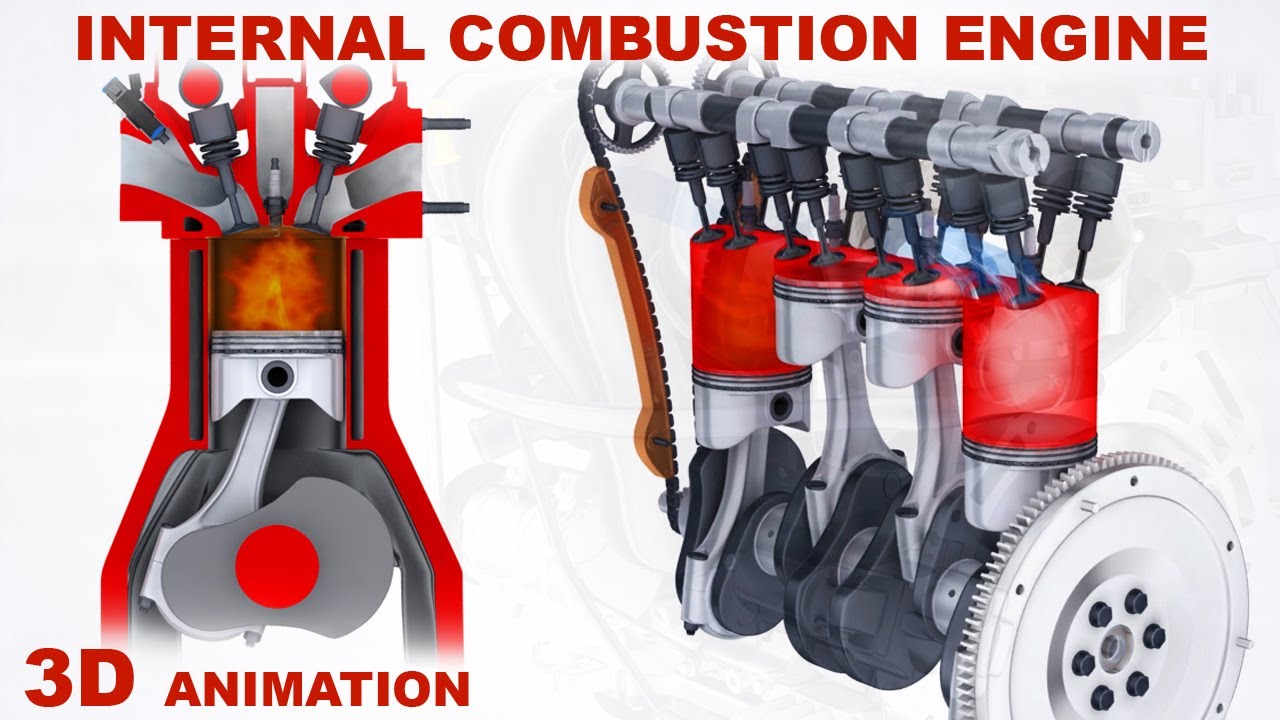

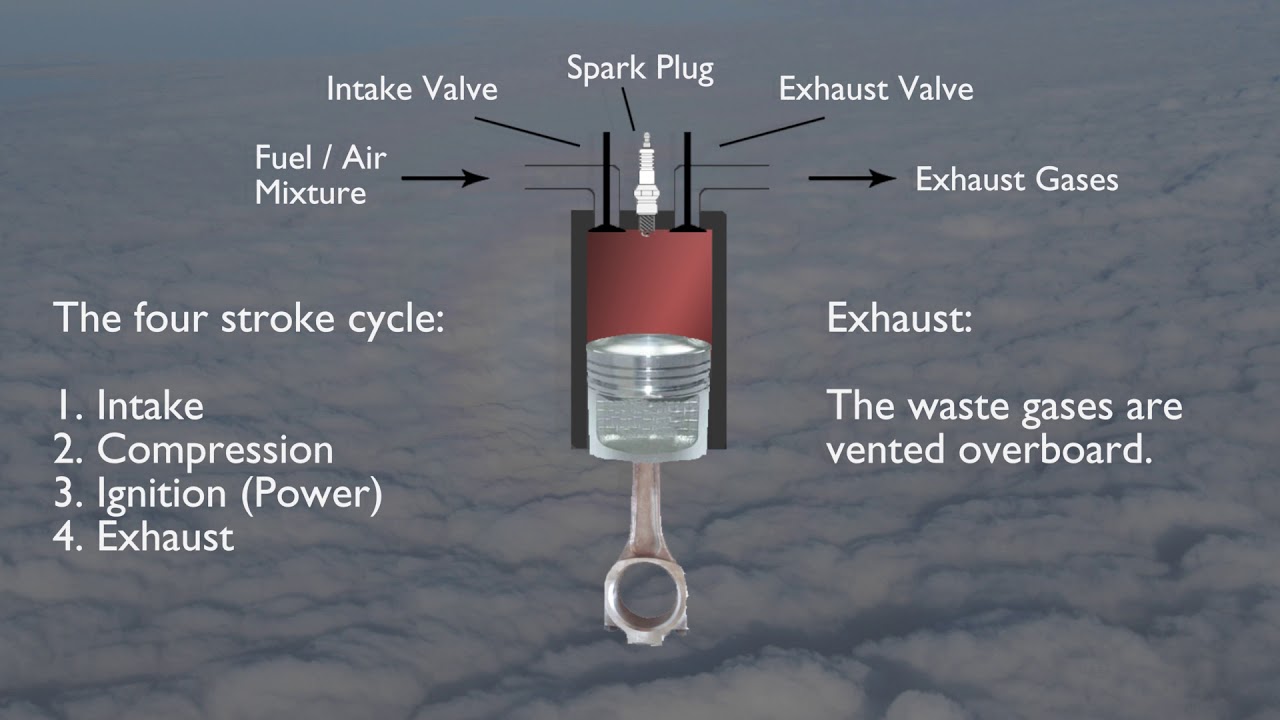

- 😀 Air enters the engine through two types of systems: natural aspiration (vacuum-driven) or forced induction (turbocharged). Turbocharged systems use a turbine to compress air, increasing air mass and engine power.

- 😀 A turbocharger works by using exhaust gases to drive a turbine that compresses incoming air, allowing for more air to enter the engine and improving performance without increasing engine size.

- 😀 Intercoolers cool the compressed air before it enters the engine, increasing air density and improving combustion efficiency, similar to a pressure cooker reducing volume through cooling.

- 😀 The use of intercoolers allows for more air molecules to fit into the same space, optimizing engine power without needing a larger engine displacement.

- 😀 The compressed air in a turbocharged engine passes through various components such as the intake manifold and the exhaust system, ensuring efficient gas flow and maintaining engine pressure.

- 😀 Effective air filtration and cooling are essential for engines in agricultural machinery, as they operate in dust-heavy environments and require optimal air conditions for maximum power and longevity.

Q & A

What is the main function of the air intake system in agricultural machinery?

-The main function of the air intake system is to supply clean, filtered air to the engine for combustion, ensuring optimal performance. It includes components like pre-filters and air filters to remove impurities before the air enters the engine.

What is the purpose of the pre-filter in agricultural machinery air systems?

-The pre-filter's purpose is to capture large particles, such as dust and dirt, from the air before it passes through the main air filter. This is especially important in agricultural settings, where there is a lot of dust due to planting, harvesting, and other operations.

What is the difference between oil bath filters and paper filters in the air intake system?

-Oil bath filters use oil to trap impurities in the air, keeping the filter moist, and are typically cleaned rather than replaced. Paper filters, on the other hand, are made of paper and are more commonly used today. They capture smaller particles and are generally replaced when clogged.

How does a naturally aspirated engine differ from a turbocharged engine in terms of air intake?

-In a naturally aspirated engine, air enters the engine through a vacuum created by the intake stroke, drawing air into the cylinders. In a turbocharged engine, exhaust gases power a turbine that compresses the air before it enters the engine, allowing for greater air intake and higher power output.

What role does the turbocharger play in increasing engine performance?

-The turbocharger increases engine performance by using exhaust gases to spin a turbine that drives a compressor. This compressor forces more air into the engine under pressure, allowing it to burn more fuel and generate more power without increasing the engine size.

Why is cooling the compressed air important in a turbocharged engine, and how is this achieved?

-Cooling the compressed air is important because compressed air heats up, and cooler air is denser, meaning it contains more oxygen. This improves combustion efficiency. The intercooler achieves this by using a heat exchanger to lower the temperature of the air before it enters the engine.

What is the function of the intercooler in a turbocharged engine?

-The intercooler's function is to cool the compressed air coming from the turbocharger. By lowering the temperature of the air, it increases its density, allowing more oxygen to enter the engine for better combustion and increased power.

How does the exhaust system contribute to the performance of a turbocharged engine?

-The exhaust system contributes to turbocharger performance by channeling exhaust gases to spin the turbine. This energy recovery from waste gases drives the compressor, which forces more air into the engine, increasing its power output.

What is the advantage of using a turbocharged engine in agricultural machinery over a naturally aspirated engine?

-The advantage of a turbocharged engine is that it can produce more power without increasing the engine size. This allows agricultural machinery to perform more efficiently, with higher output from a smaller, lighter engine, which is beneficial for operations that require more power, such as tilling or harvesting.

Why does the air need to be compressed in a turbocharged engine?

-The air is compressed in a turbocharged engine to increase its density. This allows the engine to intake more air (and therefore more oxygen) into the combustion chamber, which improves the combustion process and increases the power output of the engine.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahora5.0 / 5 (0 votes)