How Modern Factory Producing Crystal Sugar Efficiently?

Summary

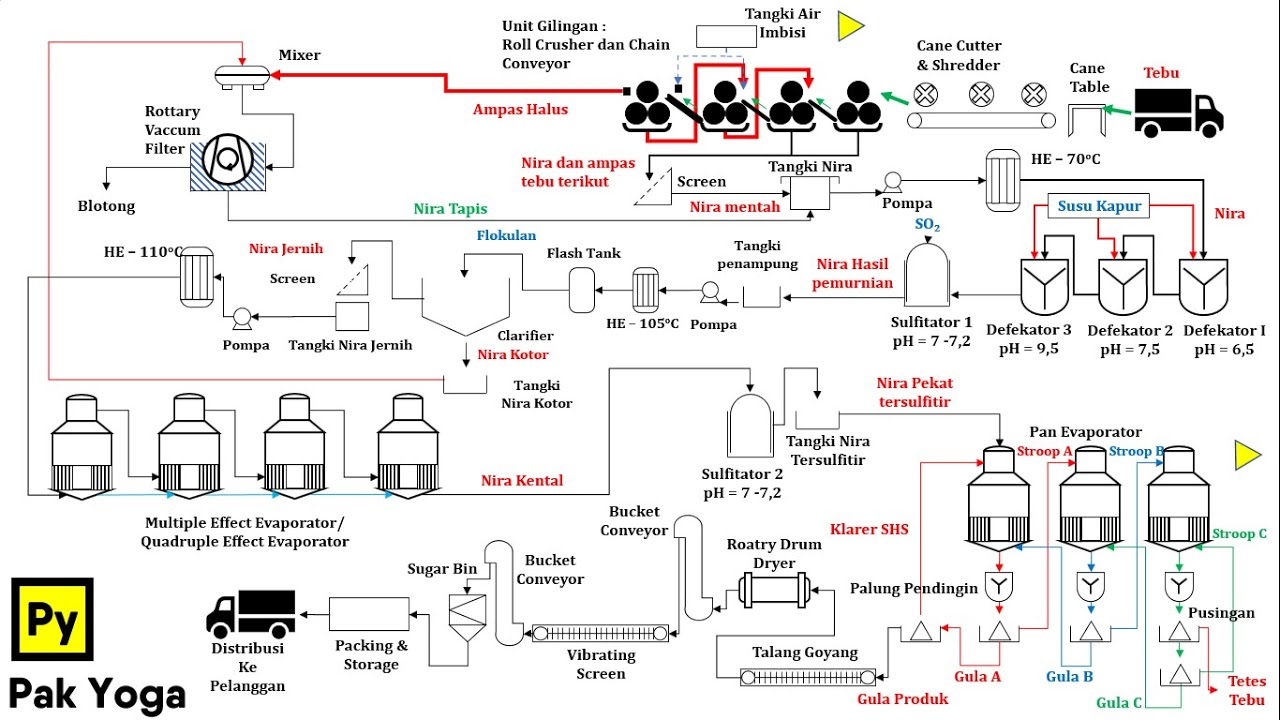

TLDRIn this video, IndoFarm provides an in-depth look at the process of turning sugarcane into white crystal sugar. The journey begins with the cultivation of sugarcane, from planting certified superior varieties to harvesting using modern machinery. After transportation to the factory, the cane undergoes cleaning, crushing, and boiling processes to separate molasses from sugar crystals. The syrup is refined and purified through centrifugation and filtration, resulting in high-quality white sugar. Viewers are taken step-by-step through the production, culminating in the packaging and distribution of the final product.

Takeaways

- 😀 Sugarcane is the primary ingredient for making granulated sugar, typically processed from sugarcane juice.

- 😀 The ideal growing conditions for sugarcane include an altitude of 500 meters above sea level and temperatures between 25°C to 30°C.

- 😀 Sugarcane is typically planted between May-August and October-November, depending on local climate conditions.

- 😀 Sugarcane reaches harvest readiness between 10-16 months of growth, with vegetative growth stopping before harvest.

- 😀 Fields are often burned for 30 minutes before harvesting to increase efficiency and reduce labor costs.

- 😀 Mechanized harvesting is used to reduce labor and machine costs, making the process more efficient.

- 😀 After harvesting, sugarcane is transported to the factory, either by lorries or train cars, for further processing.

- 😀 The first step in the factory is weighing and sampling the sugarcane for quality control before processing.

- 😀 The sugarcane undergoes a cleaning process known as 'flashing' and is then chopped to reduce its size for easier milling.

- 😀 The juice extracted from the crushed sugarcane is separated from the bagasse, which is used as fuel for electricity generation in the factory.

- 😀 The juice is boiled to concentrate it into syrup, then spun in a centrifuge to separate the sugar crystals from the molasses.

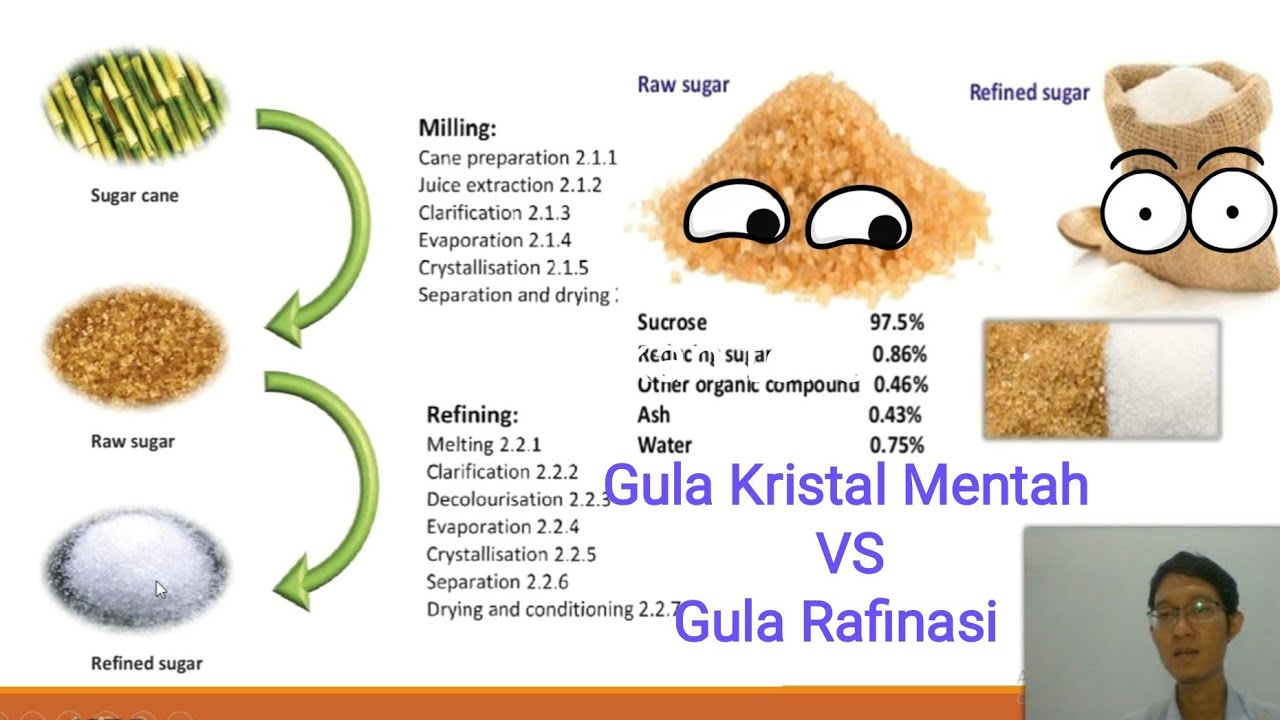

- 😀 Raw sugar is refined by mixing it with warm syrup, centrifuged again, melted, filtered, and purified through an ionized vat.

- 😀 The final refined sugar is formed into neat crystals, dried, graded, and packaged for distribution.

- 😀 Bagasse and dregs from the clarification process are recycled for use as fuel and fertilizer, supporting sustainability efforts.

Q & A

What are the ideal growing conditions for sugarcane?

-Sugarcane grows best at altitudes of 500 meters above sea level, with temperatures between 25°C and 30°C. It requires 10 to 12 hours of sunlight daily.

What type of sugarcane seeds are used for planting?

-Sugarcane is typically planted using certified superior varieties, often in the form of stem cuttings with two eyes or more.

When is the best time to plant sugarcane?

-Sugarcane is usually planted between May and August, or from October to November, depending on the local climate.

What is the optimal age for harvesting sugarcane?

-Sugarcane is ready for harvest after 10 to 16 months, when its vegetative growth stops.

How is the sugarcane harvesting process conducted?

-The harvesting process is largely mechanized, which helps reduce labor and machinery costs. The cane is harvested efficiently, with 16 hectares being burned for 30 minutes to aid the process.

What happens to the sugarcane after harvesting?

-Once harvested, the sugarcane is transported to a factory where it undergoes several processes, including weighing, cleaning, and crushing to prepare it for milling.

What is bagasse, and how is it used in sugar production?

-Bagasse is the fibrous material left over after sugarcane juice is extracted. It is used as fuel for steam boilers that generate electricity to power the production process.

What is the role of Nira liquid in sugar processing?

-Nira liquid, extracted from the sugarcane, is analyzed for sugar content. It undergoes a clarification process to remove impurities, and the remaining liquid is boiled to concentrate into syrup.

How are sugar crystals separated from molasses?

-The concentrated syrup is spun in a centrifuge to separate the sugar crystals from molasses. Hot water is added to help the crystals detach from the molasses.

What happens during the refining process of raw sugar?

-In the refining process, raw sugar is mixed with warm syrup and then centrifuged again. It is melted, filtered, and passed through an ionized vat to purify it into white crystalline sugar.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

PENGOLAHAN LIMBAH CAIR AGROINDUSTRI GULA - METODE FISIKA BIOLOGI

Kimia Industri - Diagram Alir Proses Pembuatan Gula tebu

THIS IS THE MODERN PROCESS OF SUGAR FARMING IN AUSTRALIA | THE SECRET BEHIND EXPORTED GRANULATED ...

Ekstraksi Tebu menjadi Nira - Diagram Alir Proses Industri Gula (part 1/4)

Growing and Harvesting Billions Tons of Sugarcane to make Sugar - Sugar Processing Line in Factory

Matches | How It's Made

5.0 / 5 (0 votes)