Production Systems - Facilities & Manufacturing Support Systems

Summary

TLDRThis tutorial introduces the foundational concepts of production systems, facilities, and manufacturing support systems, essential for industrial automation and computer-integrated manufacturing. It explains the evolution from manual to automated production, detailing the components of production systems, including facilities and support systems. The tutorial also covers manual, work-aided machine, and automated systems, emphasizing their roles in modern manufacturing. It outlines the functions of manufacturing support systems, including business, product design, planning, and control, which are crucial for efficient production operations.

Takeaways

- 📚 The term 'manufacturing' originates from Latin words 'manus' (hand) and 'facere' (to make), reflecting early production methods.

- 🏭 A production system encompasses people, equipment, and procedures to carry out a company's manufacturing operations.

- 🔩 Facilities are a key component of production systems, including physical structures, equipment layout, and the factory environment.

- 🛠️ Manufacturing support systems involve procedures for managing production, addressing technical and logistical challenges, and ensuring quality standards.

- 👷♂️ Direct labor in production systems includes both blue-collar workers operating facilities and white-collar workers managing support systems.

- 🔄 Production systems have evolved from manual work to work-aided machine systems and fully automated systems.

- 🤖 Automation in production systems is characterized by machines performing processes with minimal or no human intervention.

- 🔍 Manufacturing planning involves process planning, scheduling, material requirements planning, and capacity planning to ensure efficient production.

- 📈 Manufacturing control includes shop floor control, inventory control, and quality control to manage and monitor the physical production operations.

- 📊 Quality control involves inspection, data collection, and problem-solving to maintain product quality as per design specifications.

Q & A

What is the origin of the word 'manufacturing'?

-The word 'manufacturing' is derived from two Latin words 'manus' meaning hand and 'facere' meaning to make, implying that the term originally referred to items made by hand.

What are the two major components of a production system?

-A production system consists of two major components: facilities and manufacturing support systems. Facilities include the physical aspects like equipment and factory layout, while manufacturing support systems encompass the procedures for managing production.

What does the term 'facilities' in production systems refer to?

-In the context of production systems, 'facilities' refers to the physical infrastructure, including the factory, production machines, tooling, material handling equipment, inspection equipment, and computer systems that control the manufacturing operations.

How are manufacturing systems categorized based on human participation?

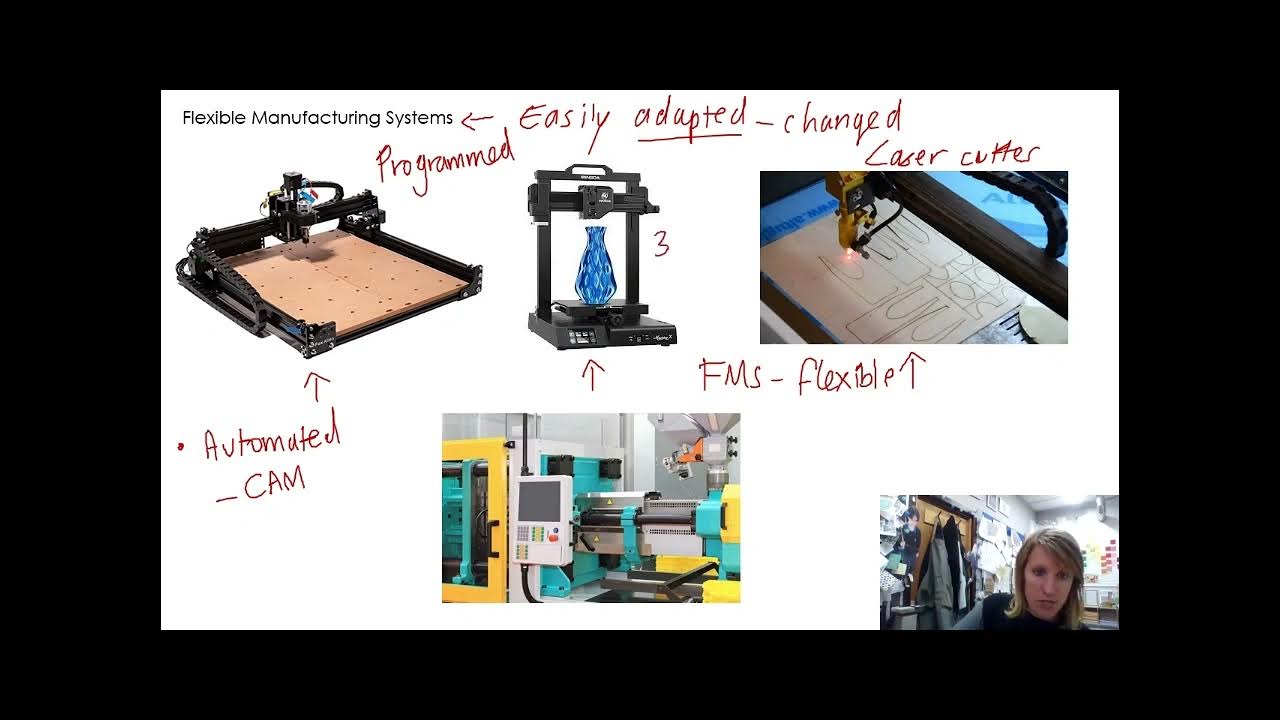

-Manufacturing systems are categorized into three basic types based on human participation: manual work systems, work-a-machine systems, and automated systems. Manual work systems involve workers using hand tools, work-a-machine systems involve human workers operating powered equipment, and automated systems perform processes without direct human participation.

What is the difference between semi-automated and fully automated systems?

-Semi-automated machines perform a portion of the work cycle under program control, requiring human intervention for the remainder of the cycle. Fully automated machines can operate for extended periods without human attention, with a worker only occasionally tending to the machine.

What are the four functions of manufacturing support systems?

-The four functions of manufacturing support systems are business functions, product design, manufacturing planning, and manufacturing control. These functions involve activities such as sales and marketing, design engineering, process planning, scheduling, and quality control.

Why are manufacturing support systems essential for efficient production?

-Manufacturing support systems are essential for efficient production as they plan and control the progress of products through the factory, manage production orders, and ensure product quality meets the specified standards.

What role do business functions play in the manufacturing process?

-Business functions serve as the primary means of communication between the company and the customer. They include sales, marketing, sales forecasting, order entry, and customer billing, and are the starting and ending points of the information processing sequence in manufacturing.

How does product design fit into the manufacturing process?

-Product design is a critical part of the manufacturing process where the product is developed and designed, either based on customer specifications or as a proprietary product by the manufacturer. This phase involves research and development, design engineering, and prototyping.

What is the purpose of manufacturing planning in production systems?

-Manufacturing planning involves process planning, master scheduling, material requirements planning, and capacity planning. Its purpose is to translate the authorization to produce a product into a feasible production plan, ensuring that all necessary materials, components, and resources are available when needed.

Can you explain the role of manufacturing control in production systems?

-Manufacturing control is responsible for managing and controlling the physical operations in the factory to implement the manufacturing plans. It includes shop floor control, inventory control, and quality control, ensuring that products are processed, assembled, and inspected according to the planned schedule and quality standards.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführen5.0 / 5 (0 votes)