Automation in Production Systems.

Summary

TLDRThis script discusses the automation of manufacturing systems, categorizing them into automated manufacturing systems and computerized manufacturing support systems. It delves into three types of automation: fixed, programmable, and flexible, each suited to different production volumes and product varieties. The script also touches on computer-integrated manufacturing (CIM), highlighting its role in product design, planning, control, and information processing, aiming to streamline manufacturing operations.

Takeaways

- 🏭 Automated manufacturing systems operate within factories to perform tasks such as processing, assembly, inspection, and material handling with minimal human intervention.

- 🔗 The automation of manufacturing systems is closely tied to computerization, which supports both the factory floor operations and the broader enterprise management.

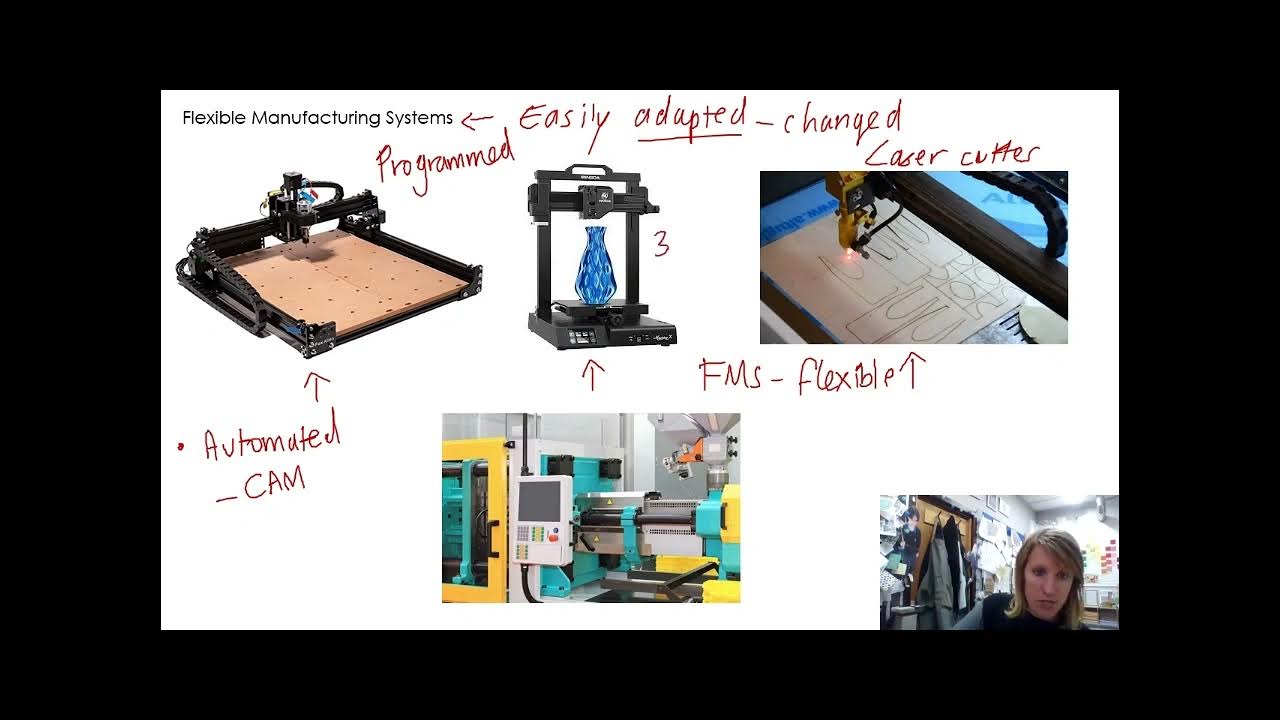

- 📊 Automated systems can be categorized into fixed automation, programmable automation, and flexible automation, each serving different production needs and volumes.

- 💼 Fixed automation is suitable for high-volume, consistent production due to its high initial investment and lack of flexibility.

- 🛠 Programmable automation allows for changes in the sequence of operations through programming, suitable for batch production with varying product configurations.

- 🔄 Flexible automation enables the production of a variety of parts or products with minimal changeover time, ideal for medium production rates and frequent design variations.

- 💡 Computerized manufacturing support systems aim to reduce manual and clerical work in product design, planning, control, and business functions.

- 🖥️ Computer-integrated manufacturing (CIM) represents the comprehensive integration of computer systems across all aspects of manufacturing, from design to production control.

- 🎛️ CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) are integral parts of CIM, supporting product design and manufacturing engineering functions.

- 📈 The implementation of CIM can lead to more efficient manufacturing processes by streamlining information flow and decision-making across the enterprise.

Q & A

What are the two categories of automation in a production system?

-The two categories of automation in a production system are the automation of the manufacturing systems in the factory and the computerization of the manufacturing support systems.

What is the difference between automated and manual operations in a production system?

-Automated operations in a production system perform tasks with a reduced level of human participation compared to the corresponding manual process. In highly automated systems, there can be virtually no human participation.

What are the examples of automated manufacturing systems?

-Examples of automated manufacturing systems include automated machine tools, transfer lines, automated assembly systems, automatic material handling and storage systems, and automatic inspection systems for quality control.

How are automated manufacturing systems classified?

-Automated manufacturing systems are classified into three basic types: fixed automation, programmable automation, and flexible automation.

What is fixed automation and what are its typical features?

-Fixed automation is a system where the sequence of processing or assembly operations is fixed by the equipment configuration. Its typical features include high initial investment, high production rates, and low flexibility to accommodate product variety.

What is programmable automation and how does it differ from fixed automation?

-Programmable automation allows the sequence of operations to be changed to accommodate different product configurations, controlled by a program. It differs from fixed automation by offering flexibility to deal with variations and changes in product configuration, and is suitable for batch production.

What is flexible automation and how does it extend programmable automation?

-Flexible automation is capable of producing a variety of parts or products with virtually no time lost for changeovers. It extends programmable automation by allowing continuous production of variable mixtures of parts or products without significant changeover times.

What is the purpose of computerized manufacturing support systems?

-The purpose of computerized manufacturing support systems is to reduce the amount of manual and clerical effort in product design, manufacturing planning and control, and the business functions of the firm.

What is computer-integrated manufacturing (CIM) and how does it relate to automation?

-Computer-integrated manufacturing (CIM) refers to the pervasive use of computer systems to design products, plan production, control operations, and perform various information processing functions in a manufacturing firm. It involves integrating all these functions into one system that operates throughout the enterprise.

What are the four basic manufacturing support functions that computer integrated manufacturing supports?

-The four basic manufacturing support functions supported by computer integrated manufacturing are business functions, product design, manufacturing planning, and manufacturing control.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Production Systems - Facilities & Manufacturing Support Systems

An Introduction to Manufacturing Engineering

Video 2 - Flexible and Lean Manufacturing

Manufacturing Systems | Industrial Automation

RAMI 4.0: Reference Architecture Model for Industry 4.0 Explained - Industry 4.0 Tutorial [3 of 6]

Manufacturing Metrics | Performance and Cost

5.0 / 5 (0 votes)