In The Materials Lab Non Destructive Testing Network Rail engineering education 15 of 15

Summary

TLDRThis video script delves into the world of non-destructive testing (NDT), showcasing various techniques like dark penetrant testing, magnetic particle inspection, and ultrasonic testing to detect defects in materials without causing damage. It highlights the importance of these methods in ensuring safety and quality in industrial applications. The script also touches on the use of sophisticated equipment like the scanning electron microscope for high-magnification imaging and forensic engineering, demonstrating the broad applications of NDT in both industry and legal investigations.

Takeaways

- 🔍 Non-destructive testing (NDT) is vital in industry for evaluating materials without causing damage, allowing tested components to be reused.

- 🛠️ Dye penetrant testing helps detect surface-breaking defects by using a dye to reveal cracks or open pores that could lead to component failure.

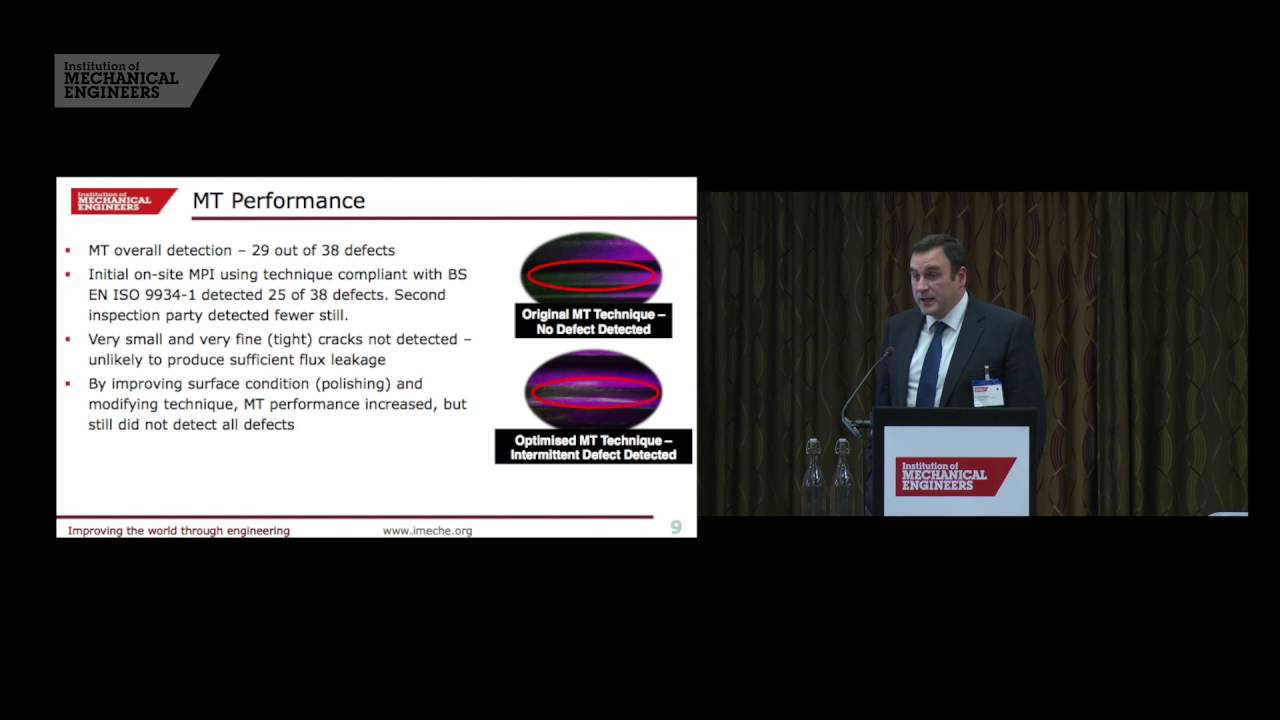

- ⚙️ Magnetic particle inspection is used to detect subsurface defects in magnetic materials by inducing a magnetic field and applying magnetic ink.

- 🔧 Ultrasonic testing is a powerful method for detecting internal defects deep within a material, such as gas porosity or tiny cracks.

- 🧲 Magnetic particle inspection can't be used on non-magnetic materials, but it allows for slightly deeper inspection than dye penetrant testing.

- 💡 Ultrasonic testing is similar to medical ultrasounds, using sound waves to detect internal flaws in a material, even meters deep.

- 🔬 Scanning electron microscopy offers extremely high magnification and resolution, allowing for detailed analysis at the atomic level.

- 🧪 The scanning electron microscope can be used for both imaging and chemical analysis, making it useful for materials development and forensic investigations.

- 🚗 Forensic engineering uses principles of physics, chemistry, and materials science to analyze failures, such as determining if a car's headlight was on during an accident.

- 🧬 The scanning electron microscope has diverse applications, from developing new materials to solving forensic cases and enhancing existing materials.

Q & A

What is non-destructive testing and why is it important in industry?

-Non-destructive testing (NDT) is a broad group of analysis techniques used in science and industry to evaluate the properties of a material without causing damage. It is crucial in industry because it allows components to be tested for integrity without being destroyed, ensuring they can continue to be used after testing.

What are the key components used in a dark penetrant test?

-The key components used in a dark penetrant test include a dye penetrant, cleaning fluid, and a developer, which is a substance similar to talcum powder. These are used to detect open pores or surface-breaking cracks.

How long should the penetrant be left on the sample during a dark penetrant test?

-The penetrant should be left on the sample for about 20-30 minutes to allow sufficient time for it to seep into any surface-breaking defects.

What is the purpose of the developer in a dark penetrant test?

-The developer in a dark penetrant test is used to draw the penetrant back out of any defects, revealing them as visible indications on the surface of the material.

What is magnetic particle inspection and how does it differ from dark penetrant testing?

-Magnetic particle inspection is a method of NDT that uses magnetic particles to detect surface and slightly subsurface defects in ferromagnetic materials. It differs from dark penetrant testing in that it requires the material to be magnetizable, whereas dark penetrant testing is not limited by material type.

What materials can be tested with ultrasonic testing?

-Ultrasonic testing can be used on a wide range of materials, including metals, plastics, and ceramics. It is particularly useful for detecting internal defects such as cracks, gas porosity, and inclusions that may be far from the surface.

How does a scanning electron microscope (SEM) contribute to materials engineering?

-A scanning electron microscope allows materials engineers to examine materials at very high magnifications and resolutions, providing detailed images and chemical analysis. This capability is crucial for developing and enhancing materials, as well as for forensic engineering applications.

What is forensic engineering and how does it utilize the scanning electron microscope?

-Forensic engineering applies the principles of math, physics, and chemistry to support legal arguments, often involving the investigation of failures or accidents. A scanning electron microscope is used in forensic engineering to analyze materials at the microscopic level, providing evidence such as whether a vehicle's light was on during a collision.

How does the scanning electron microscope create an image of the sample?

-The scanning electron microscope creates an image by directing a focused beam of electrons onto the sample's surface. The electrons interact with the sample, producing signals that are detected and used to form an image on a screen.

What is the significance of the globules observed on the tungsten filament in a forensic investigation?

-The globules observed on the tungsten filament in a forensic investigation indicate that the filament was hot at the time of the collision, suggesting that the light was on. This is deduced from the presence of silica globules, which are a result of the filament's heat causing the glass from a broken bulb to melt and form globules upon impact.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآن5.0 / 5 (0 votes)