Fuselages - Part I: Preliminary considerations

Summary

TLDRThis presentation series explains the analysis of planes with fuselages using flow5, highlighting the significant impact of fuselage inclusion on performance. It covers the necessary steps, including geometry construction, mesh generation, and critical review of results, emphasizing the importance of correctly connecting wing and fuselage meshes and the use of boundary element methods.

Takeaways

- 🛫 The presentation is a 5-part series focusing on analyzing the aerodynamics of a plane with a fuselage using Flow5.

- 🛠 Unlike xflr5, Flow5 has all the necessary tools for analyzing a plane with a fuselage, both theoretically and numerically.

- 📊 Including the fuselage in the analysis can significantly affect performance, as shown by the difference in polar graphs between the blue (without fuselage) and red (with fuselage) curves.

- ⚠️ The inclusion of the fuselage requires careful construction of geometries and surface meshes, and a critical review of results to avoid errors.

- 🔍 The main challenge is ensuring the union of surface mesh elements forms closed, non-intersecting volumes, which is crucial for the boundary element methods used in Flow5.

- 🛑 It's important to connect wing meshes to the fuselage mesh without leaving panels inside the wing thickness and avoiding volume intersections.

- 🔨 Flow5 uses the open cascade API to build closed volumes, which requires closed trailing edges for wings and careful handling of half-wings like fins.

- 💻 The presenter implemented a custom mesher using the advancing front method due to issues with existing open-source meshers.

- 📏 Mesh quality is crucial, and special attention should be given to avoiding small edges, which can cause high local triangle counts and mesh sizes.

- 🔗 When connecting wing and fuselage meshes, Flow5 aligns nodes, but manual adjustment may be needed for edges crossing the wing root section.

- 🌐 After connecting meshes, the triangle mesh needs to be connected, which can be done automatically or manually, with free edges highlighted for review.

- 📉 The analysis results are derived from doublet densities, so it's essential to ensure these densities are calculated correctly and exhibit no unusual patterns.

Q & A

What is the main purpose of the 5-part presentation?

-The main purpose of the presentation is to explain how to run the analysis of a plane with a fuselage using flow5, emphasizing the importance of including the fuselage in the analysis for accurate results.

What is the difference between the results shown by the blue and red curves in the polar graphs?

-The blue curve corresponds to the case without a fuselage, while the red curve includes the fuselage. The difference highlights the significant drop in performance when the fuselage is considered, such as in glide ratio and drag polar.

Why is it important to include the fuselage in the analysis?

-Including the fuselage is important because it has a significant influence on the plane's performance and can affect results like glide ratio and drag polar, as shown in the polar graphs.

What are the challenges in including the fuselage in the analysis?

-The challenges include building and constructing the geometries and surface mesh carefully, ensuring that the union of surface mesh elements defines one or more closed, non-intersecting volumes, and avoiding intersections between volumes like the tail end.

What is the role of the open cascade API in flow5?

-The open cascade API is used by flow5 to build closed volumes, which is essential for connecting the wings to the fuselage mesh and ensuring that individual volumes form closed solids.

Why is it necessary to close the trailing edges of the wings in the analysis?

-Closing the trailing edges of the wings is necessary to form closed volumes that can be connected to the fuselage, which is a requirement for the boundary element methods used in flow5.

What issues did the presenter encounter with open-source meshers, leading to the development of a custom mesher?

-The presenter encountered various issues with existing open-source meshers, which led to the development of a custom mesher using the advancing front method for better performance and quality in most cases.

What are the considerations to ensure a good quality mesh in the custom mesher?

-The considerations include defining the geometry as a union of faces with closed contours, avoiding free edges, and being cautious about small edges that can lead to high mesh sizes and numerical issues.

How does flow5 handle the connection between the wing mesh and the fuselage mesh?

-Flow5 ensures that the fuselage nodes fall opposite the wing nodes, with the exception of edges in the fuselage that cross the wing root section, which may require manual adjustment.

What is the significance of the wake panels or vortices extending from the wing trailing edges in flow5?

-The wake panels or vortices are significant because they need to be checked for intersection with downstream parts, ensuring that elements like the elevator are not located in the same horizontal plane as the main wing.

How does the presenter suggest analyzing a plane with its fuselage for the best results?

-The presenter suggests using the thick triangular panel method with linear doublet densities, simplifying and cleaning the geometry before import, and ensuring a good mesh quality for accurate analysis.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

Aircraft Structures - Airframe Construction - Airframes & Aircraft Systems #2

Foils in flow5

How do SQL Indexes Work

Dholera Smart City | Gujarat | Drone View | Tata Semiconductor Company

Transformes for Time Series: Is the New State of the Art (SOA) Approaching? - Ezequiel Lanza, Intel

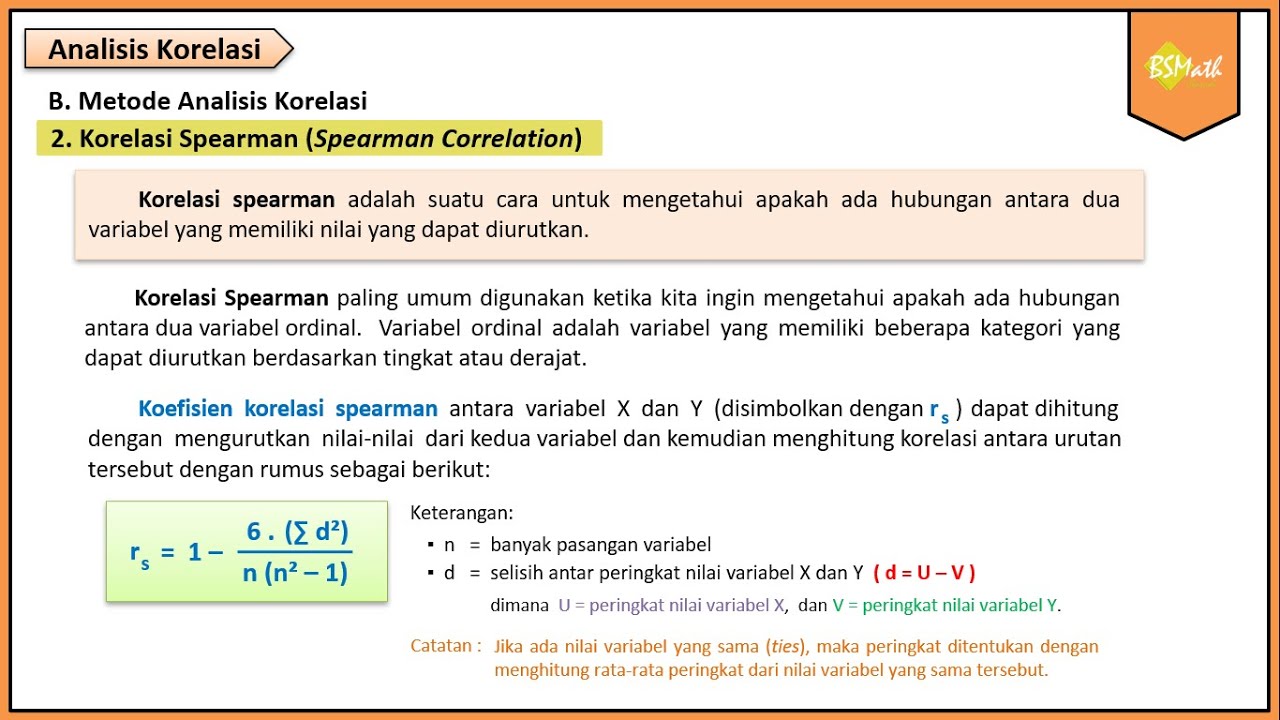

Korelasi Spearman - Matematika Wajib SMA Kelas XI Kurikulum Merdeka

5.0 / 5 (0 votes)