How Does a Waterjet Work? It Slices Steel with Water!

Summary

TLDRWater jet cutting is a powerful industrial technology that uses high-pressure water, sometimes mixed with abrasive particles, to slice through tough materials like steel, granite, and titanium. This cold cutting method avoids the heat distortion common with other tools, making it ideal for precise, intricate cuts without producing smoke, dust, or hazardous fumes. Water jet cutters can achieve extreme accuracy with tolerances as tight as 0.1 millimeters, making them valuable in fields like aerospace, architecture, and even culinary arts. The process demonstrates how water, under intense pressure, can cut through the hardest materials, showcasing the power of physics and engineering.

Takeaways

- 😀 Water jet cutting uses a high-pressure jet of water to slice through materials like metal, stone, and even food.

- 😀 The process works by eroding materials with water at pressures up to 6,000 bars, far beyond a typical fire hose.

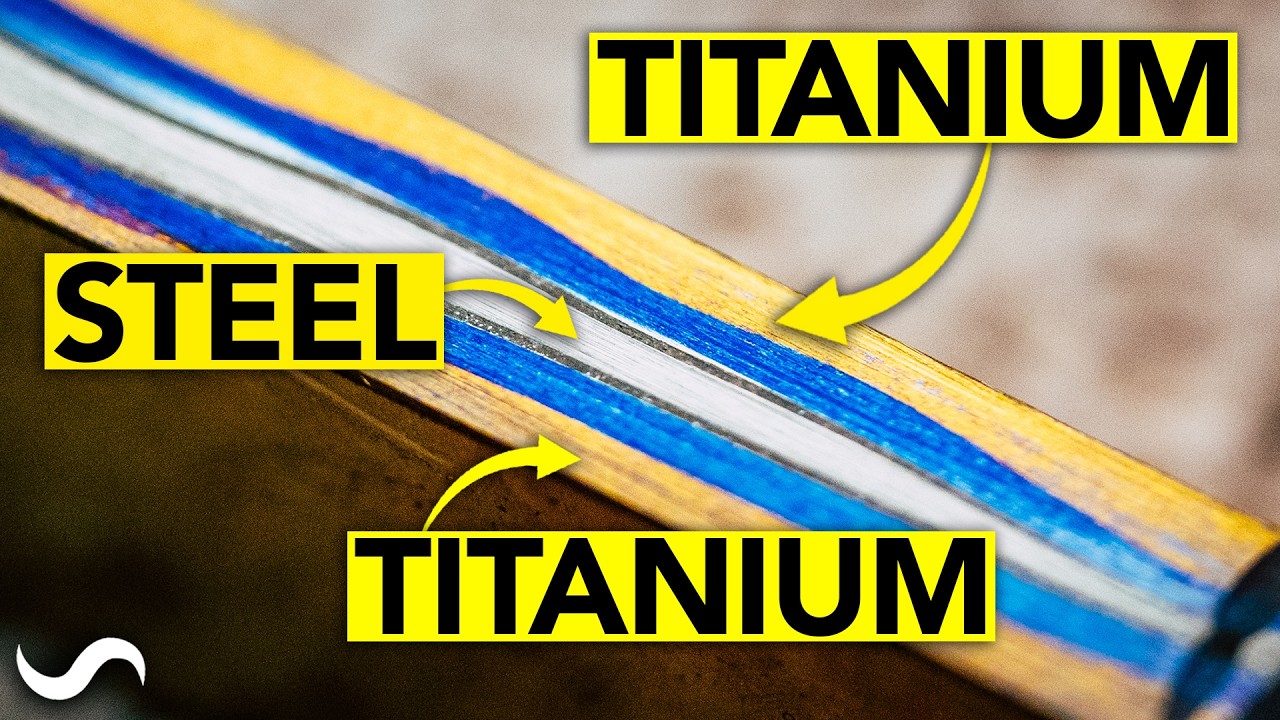

- 😀 When cutting harder materials like metal or stone, the water is mixed with abrasive materials, like garnet, to enhance cutting power.

- 😀 Water jet cutting operates without generating heat, making it ideal for materials sensitive to temperature changes.

- 😀 One key advantage of water jet cutting is its ability to cut cleanly without causing thermal distortion, warping, or burning.

- 😀 The precision of water jet cutting is remarkable, with tolerances as tight as 0.1 millimeter, making it suitable for intricate designs.

- 😀 Water jet cutters can be controlled by computer numerical control (CNC) systems, allowing for highly accurate, programmable cuts.

- 😀 The machine uses a small, synthetic sapphire or diamond nozzle that focuses the water jet into a supersonic stream, reaching speeds of up to 900 m/s.

- 😀 Water jet cutting can be used in various industries, from aerospace engineering to creating art, including cutting delicate materials like pastries.

- 😀 The process is eco-friendly, as the water used in water jet cutting can often be recycled through a closed-loop system, minimizing waste.

Q & A

What is water jet cutting?

-Water jet cutting is a machining process that uses a high-pressure jet of water to slice through materials. It can also incorporate abrasive materials like garnet to cut through harder substances such as metal, granite, and titanium.

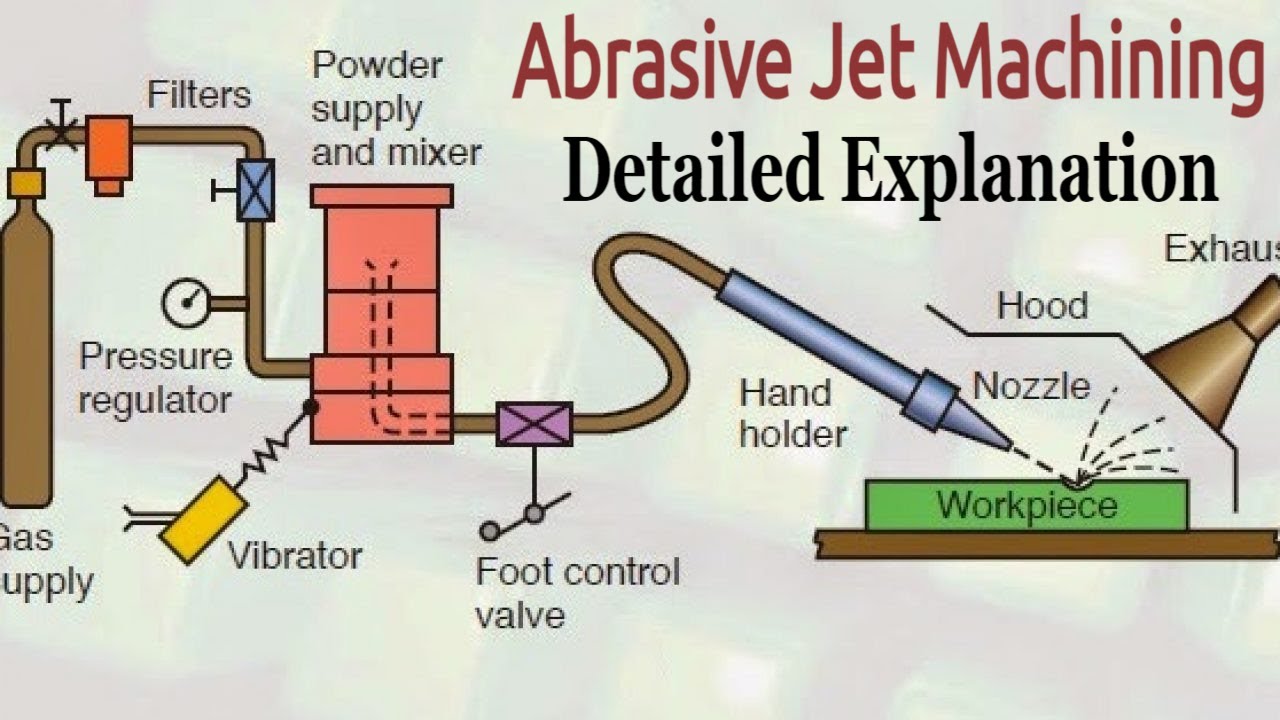

How does water jet cutting work?

-Water jet cutting works by pressurizing water to extremely high levels (up to 6,000 bars or 90,000 PSI) and directing it through a narrow nozzle. For tougher materials, abrasive particles are added to the water, creating a high-speed abrasive slurry that erodes the material.

What types of materials can water jet cutting be used on?

-Water jet cutting can be used on a variety of materials, including soft ones like rubber, plastic, wood, and food, as well as hard materials like granite, titanium, and steel.

Why is water jet cutting so effective?

-Water jet cutting is effective because it combines high water pressure with abrasive particles, allowing it to erode and slice through tough materials. The process is precise, cold, and doesn't generate heat, making it ideal for sensitive materials.

What is the role of the nozzle in water jet cutting?

-The nozzle in water jet cutting is a tiny opening, often made of synthetic sapphire or diamond, that focuses the high-pressure water into a razor-sharp, supersonic jet. This focused stream enables the machine to cut through tough materials with precision.

How does the addition of abrasive materials affect water jet cutting?

-The addition of abrasive materials like garnet or sand transforms the water jet into a high-speed slurry that can effectively erode hard materials like metal or stone. The abrasive particles act like microscopic sandblasters, helping to grind away at the material.

What makes water jet cutting a cold process?

-Water jet cutting is considered a cold process because it does not generate significant heat during the cutting. Unlike plasma cutters or lasers, it doesn't melt or warp the material, which is crucial for materials sensitive to heat.

What are the benefits of water jet cutting in terms of safety and environmental impact?

-Water jet cutting is safer compared to other methods because it doesn't produce smoke, dust, or hazardous fumes. Additionally, it is eco-friendly since the water used in the process can often be recycled through a closed-loop system.

What level of precision can water jet cutting achieve?

-Water jet cutting can achieve extremely precise cuts, with tolerances as tight as 0.1 millimeters. This makes it suitable for intricate and detailed work, such as etching patterns into glass or cutting complex parts for aerospace applications.

How does water jet cutting compare to traditional methods like plasma or laser cutting?

-Water jet cutting is superior in certain cases because it is a cold cutting process, avoiding the heat-affected zones that plasma or laser cutting can cause. This allows it to cut sensitive materials more precisely without warping or altering their structure.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

WATER JET MACHINE PROCESS : Working of abrasive water Jet machining process (animation).

This Should Be Impossible...

How an Abrasive Jet Machining Works?

Materiais e Processos de Fabricação para Engenharia de Produção: Usinagem não convencional

Electrochemical Grinding Process | How electrochemical grinding works

The Anatomy of a Sly Impinjet Wet Scrubber

5.0 / 5 (0 votes)