Materiais e Processos de Fabricação para Engenharia de Produção - Usinagem convencional: Exercícios

Summary

TLDRThis video lesson covers key concepts in machining processes, focusing on conventional machining with defined tool geometry. It includes practical exercises on turning, drilling, and milling, illustrating essential calculations for each process. The lesson walks through the steps to calculate cutting speed, material removal rate, rotation speed, and other factors for turning, drilling, and milling operations. The content is geared toward production engineering students, with detailed problem-solving methods and the use of relevant formulas to enhance understanding of machining processes. The lesson concludes with an introduction to non-conventional machining methods for the following week.

Takeaways

- 😀 The video lesson covers basic machining processes such as turning, drilling, and milling, focusing on their respective calculations and applications in manufacturing.

- 😀 Turning is explained with a detailed exercise where the goal is to reduce the diameter of a stainless steel workpiece, using concepts like cutting speed, material removal rate, and feed rate.

- 😀 A formula for calculating cutting speed is provided: the speed of cutting (V) is related to the rotational speed (RPM) and diameter of the piece, with results in millimeters per minute for the given units.

- 😀 Material removal rate is calculated using the cutting speed, cutting depth, and feed per revolution, highlighting how these factors contribute to the efficiency of the machining process.

- 😀 Drilling operations are analyzed using an exercise with a high-speed steel drill bit, with calculations for RPM, approach distance, cutting time, and material removal rate.

- 😀 In the drilling example, cutting speed is used to calculate the optimal rotational speed (RPM), and the geometry of the drill bit is considered for calculating approach distance using trigonometric relations.

- 😀 Time to perform a drilling operation is calculated using the formula that incorporates workpiece thickness, approach distance, and feed rate, with a focus on converting feed per revolution to feed per minute.

- 😀 Milling is demonstrated using an example with a face mill and multiple teeth. Calculations for RPM, approach distance, and machining time are included, considering the tool's diameter and number of teeth.

- 😀 For milling, cutting speed, tool diameter, and the number of teeth are key parameters for calculating RPM and material removal rate, similar to turning and drilling operations.

- 😀 The total machining time for milling is derived by considering the length of the workpiece, approach distance, tool engagement, and feed rate, with all these values factored into the final calculation.

- 😀 Throughout the video, the importance of understanding basic machining parameters such as cutting speed, feed rate, tool geometry, and RPM is emphasized to optimize manufacturing processes.

Q & A

What is the main focus of this video lesson?

-The main focus of the video lesson is to explain the calculation and principles behind various conventional machining processes such as turning, drilling, and milling, including the relevant formulas and calculations involved in these processes.

What is the diameter reduction process in the turning exercise?

-In the turning exercise, a stainless steel part with an initial diameter of 12.5 mm is reduced to a final diameter of 12 mm by using a turning operation, where the tool cuts the material as the piece rotates.

How is cutting speed calculated for turning?

-Cutting speed for turning is calculated using the formula: V = (π × D × N) / 1000, where V is the cutting speed in mm per minute, D is the initial diameter of the piece in millimeters, and N is the rotational speed in RPM.

What is the formula for material removal rate in turning?

-The material removal rate (MRR) in turning is calculated using the formula: MRR = Vc × d × f, where Vc is the cutting speed, d is the depth of cut, and f is the feed rate per rotation.

What is the depth of cut in the turning process and how is it calculated?

-The depth of cut in the turning process is calculated by the difference between the initial and final diameters of the piece, divided by two. In this case, the depth of cut is (12.5 mm - 12 mm) / 2 = 0.25 mm.

How is the feed rate for turning determined?

-The feed rate for turning is determined by dividing the linear feed speed by the rotational speed of the piece. In this case, with a linear feed speed of 200 mm/min and a rotational speed of 400 RPM, the feed rate per rotation is 0.5 mm/rotation.

What formula is used to calculate the rotation speed for drilling?

-For drilling, the rotation speed (RPM) is calculated using the formula: RPM = (1000 × Vc) / (π × D), where Vc is the cutting speed in meters per minute and D is the diameter of the drill in millimeters.

What is the significance of the 'approach' distance in drilling?

-The 'approach' distance in drilling refers to the distance the drill bit travels before it begins cutting the material. It is the vertical distance from the tip of the drill to the point where the cutting begins.

What is the formula to calculate the material removal rate for drilling?

-The material removal rate for drilling is calculated using the formula: MRR = (π × D² × V) / 4, where D is the drill diameter, and V is the feed rate in millimeters per minute.

What is the formula for calculating the rotation speed for milling?

-For milling, the rotation speed (RPM) is calculated using the formula: RPM = (1000 × Vc) / (π × D), where Vc is the cutting speed in millimeters per minute and D is the diameter of the milling cutter in millimeters.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

Introduction: Advanced Machining Processes

Materiais e Processos de Fabricação para Engenharia de Produção - Usinagem convencional: conceitos

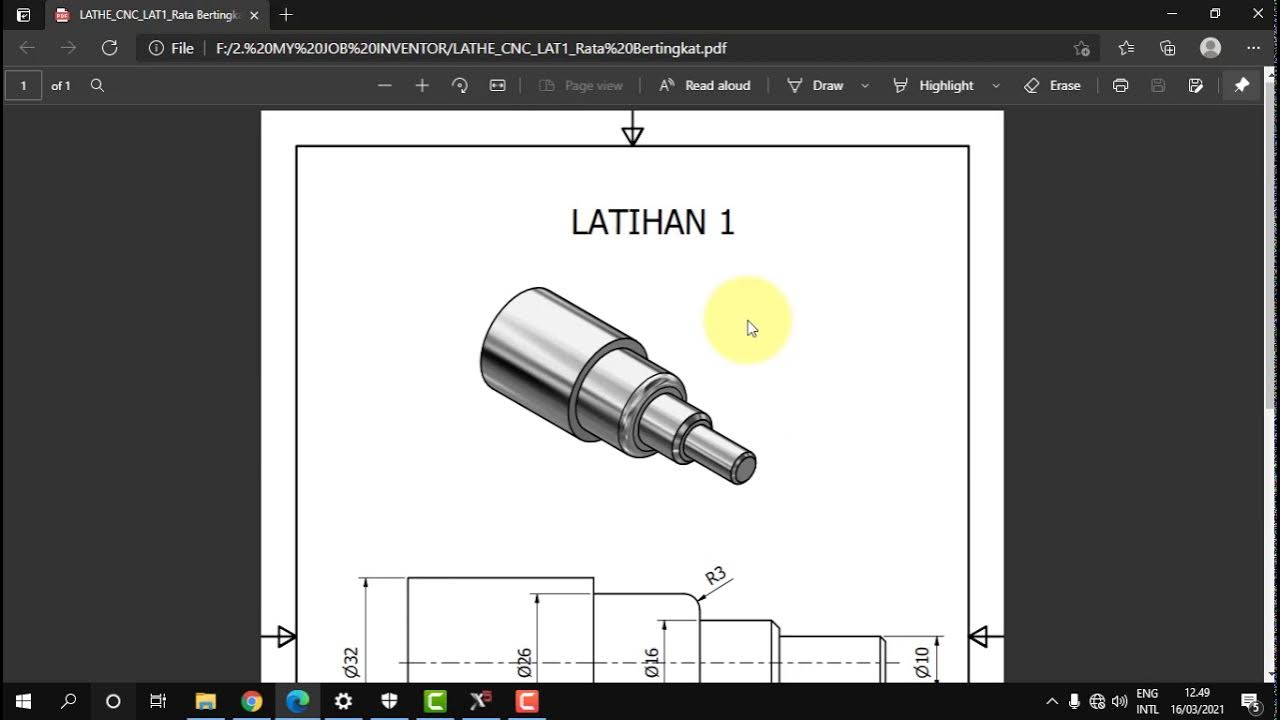

MASTERCAM X5_BUBUT DASAR BIDANG BERTINGKAT

Mastercam Mill 3D || Pocket Roughing || Surface High Speed Rough Tool paths | @VirenderSinghBhati

Milling machine tutorial - cutter selection, speeds and feeds, coolant, high speed machining

Materiais e Processos de Fabricação para Engenharia de Produção - Usinagem não convencional...

5.0 / 5 (0 votes)