Mastercam Mill 3D || Pocket Roughing || Surface High Speed Rough Tool paths | @VirenderSinghBhati

Summary

TLDRThis Mastercam 3D tutorial focuses on tool preparation and machining processes. It covers the steps to prepare tools, set machining parameters, and handle various tool types for different components. The video dives into topics such as pocketing, surface parameters, and material handling, all aimed at ensuring smooth machining. It also highlights essential steps for creating solid models, tool selection, and managing program numbers. Viewers can learn how to apply different methods, including refitting and tool entry options, for optimized machining results in Mastercam, with an emphasis on achieving precise and efficient outcomes.

Takeaways

- 😀 Tool preparation for machining is essential, and the video provides a guide to setting up various tools and parameters for Mastercam Mill 3D.

- 😀 The tutorial covers different types of tooling methods, including refitting and using tools for specific tasks.

- 😀 Parameters such as spindle speed, cutting depth, and feed rates are crucial for efficient machining, and the video discusses how to set them up in Mastercam.

- 😀 It explains the process of preparing a component for machining, including how to select appropriate tools and adjust settings based on material type.

- 😀 Pocketing operations are demonstrated with an emphasis on creating smooth cuts using Mastercam's features for pocket creation and parameter adjustments.

- 😀 Understanding entry options and selecting appropriate tool paths are key for successful machining; this includes determining the best start points and tool movements.

- 😀 The video explains how to select different surface parameters for machining, optimizing tool paths for surface finishing.

- 😀 In-depth discussion on the importance of material selection, ensuring the right materials are used for specific tasks to improve machining efficiency.

- 😀 Step-by-step instructions for setting up boundary lines and machining paths are provided to ensure precision during operations.

- 😀 The video emphasizes the use of simulations and toolpath verification before actual machining to avoid errors and ensure accuracy in the final product.

- 😀 The tutorial concludes by showing how to use the Mastercam tool library, enabling easy access to various tools and settings for future operations.

Q & A

What is the primary topic discussed in the video?

-The video primarily discusses how to prepare tool paths and machining strategies in Mastercam for 3D milling. It covers various tool setups, parameters, and machining techniques.

What are the two types of tools mentioned in the script?

-The two types of tools discussed in the script are 'Refit' and 'Pysindur' tools, which are used for different machining operations in Mastercam.

How are tool paths generated in Mastercam according to the script?

-Tool paths are generated in Mastercam by setting up the correct parameters and selecting appropriate tools for machining. The software helps in generating the tool paths by utilizing predefined settings and components for accurate machining.

What is the significance of parameter settings in Mastercam?

-Parameter settings in Mastercam are crucial as they define the machining conditions, such as tool speed, feed rate, and material type, ensuring accurate and efficient machining operations.

How does the script describe the process of preparing a tool for machining?

-The script highlights that preparing a tool involves selecting the right tool for the job, adjusting tool parameters such as speed and feed rates, and ensuring proper settings for the material being machined.

What role does material selection play in machining, according to the script?

-Material selection plays a vital role as it influences the machining parameters like cutting speed, tool wear, and the overall efficiency of the machining process. Different materials require different tool settings for optimal results.

What is mentioned about the 'floating solid' in the context of the video?

-The 'floating solid' refers to a method in Mastercam used to define the geometry or toolpath that automatically adjusts, ensuring smooth machining of the component during the process.

Can the script help users understand surface parameter settings?

-Yes, the script discusses surface parameter settings, including clearance, depth of cut, and other factors that influence how the tool interacts with the material surface during machining.

What are the steps for setting up a pocket operation in Mastercam?

-The script explains that setting up a pocket operation involves selecting the pocket geometry, defining the tool entry point, and adjusting parameters such as tool size, step-down depth, and feed rates to ensure efficient cutting.

How does the video address the topic of tolerance and its importance?

-The video touches on tolerance by explaining how it affects the accuracy of the final product. Proper tolerance settings ensure that parts are machined within the required specifications, avoiding errors during production.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

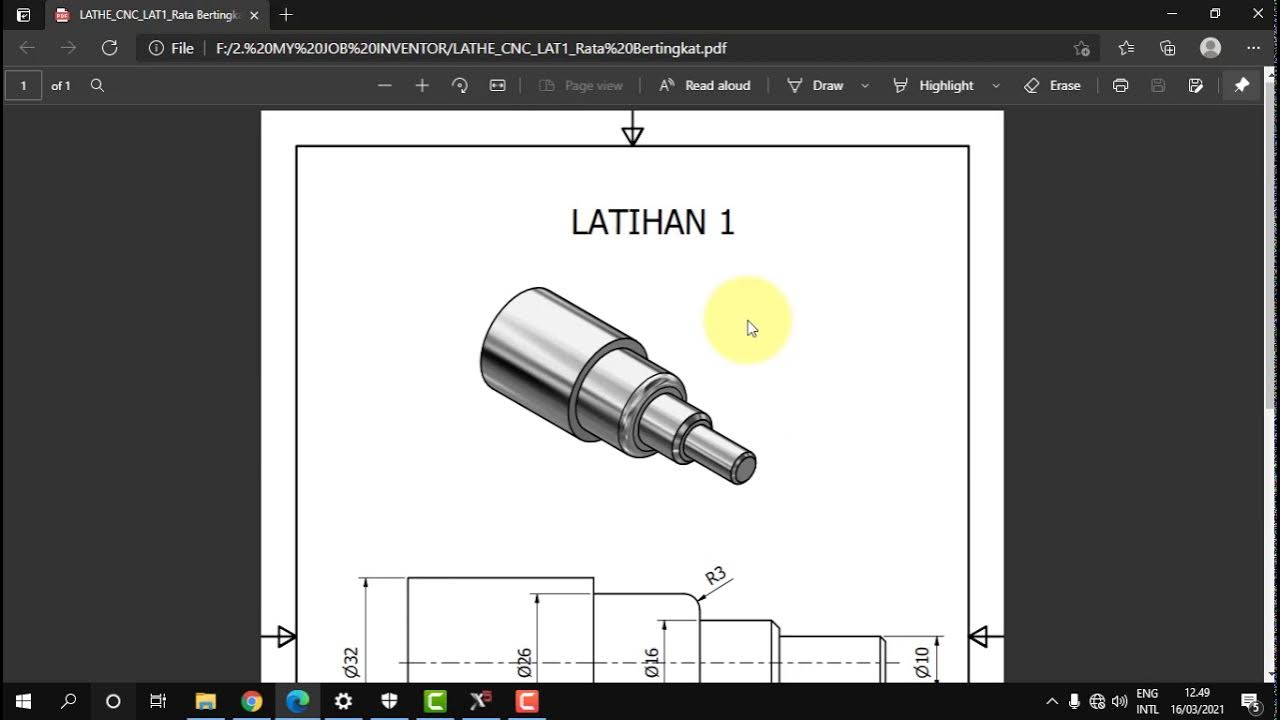

MASTERCAM X5_BUBUT DASAR BIDANG BERTINGKAT

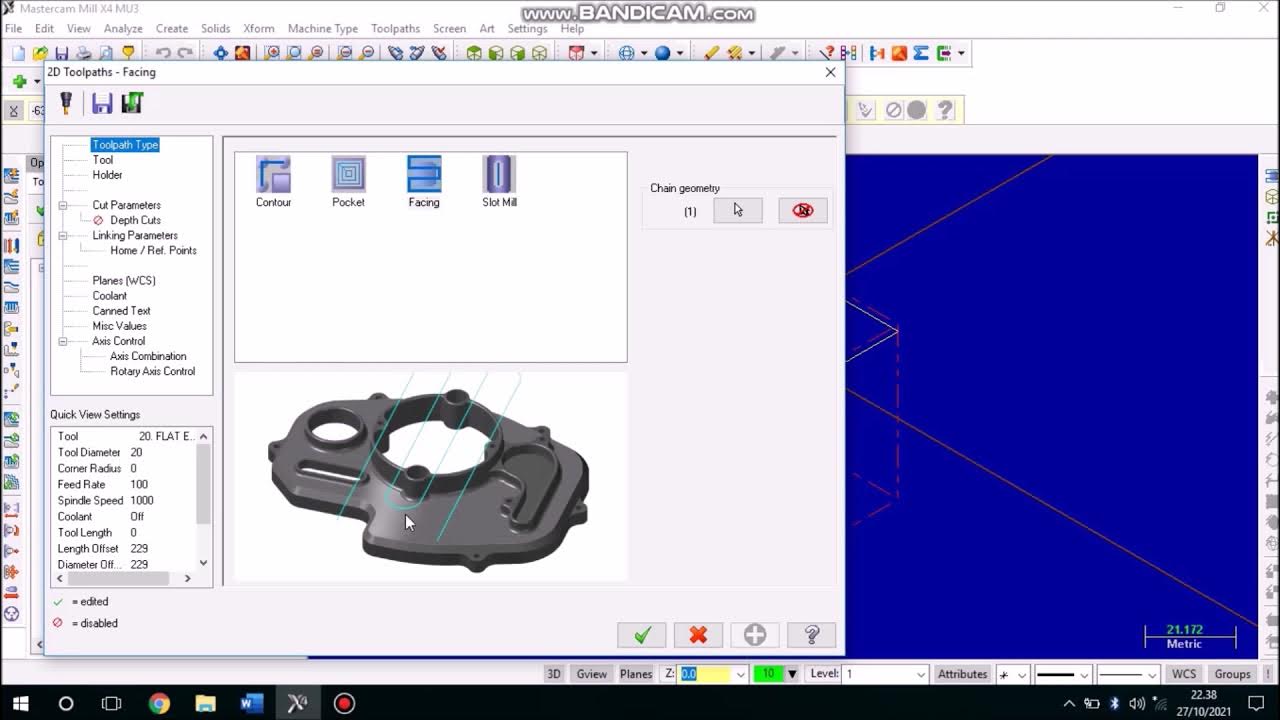

Job Facing Master CAM Mill

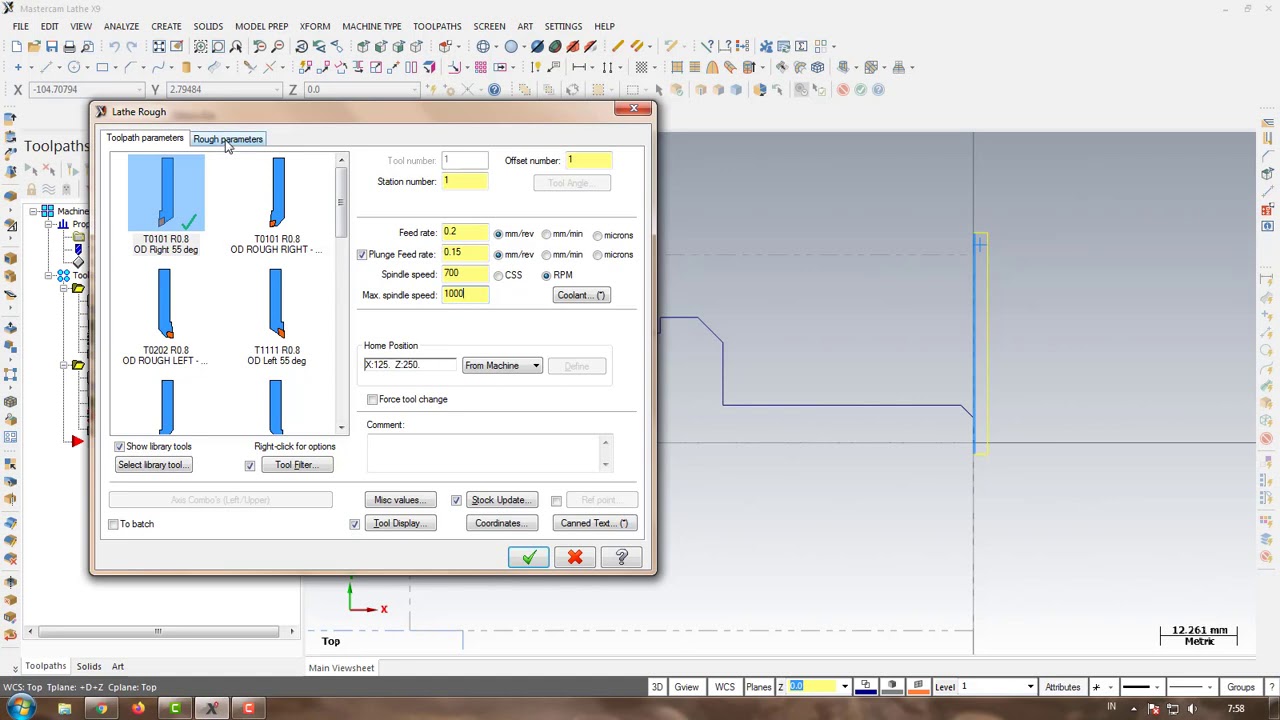

Program CNC Turning Menggunakan MasterCAM X9 (Pembuatan PIN)

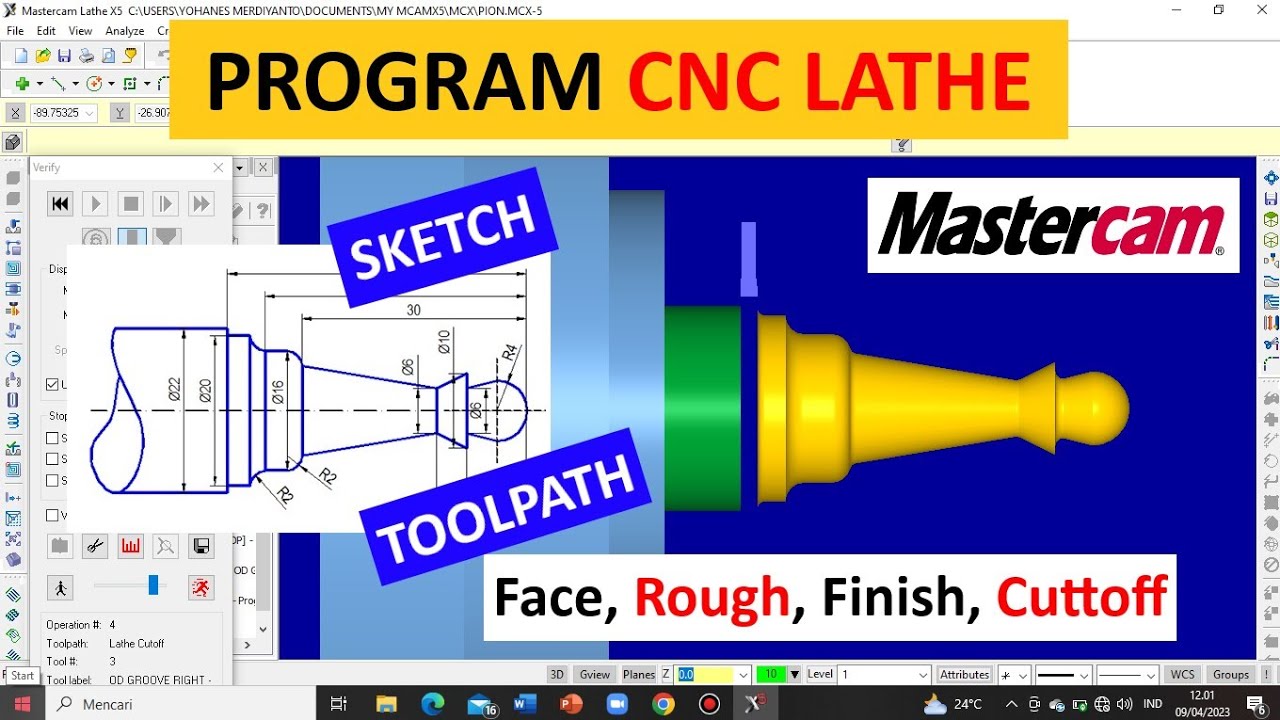

TUTORIAL MASTERCAM X5 MEMBUAT PION || CNC Turning (Lathe) || Simpel & Mudah dipahami !!

#1 - Pengenalan MasterCam

Cara membuat LOGO dan Tulisan pada software Mastercam 2017 - Logo Barcelona

5.0 / 5 (0 votes)