caracteristicas de los instrumentos de medicion

Summary

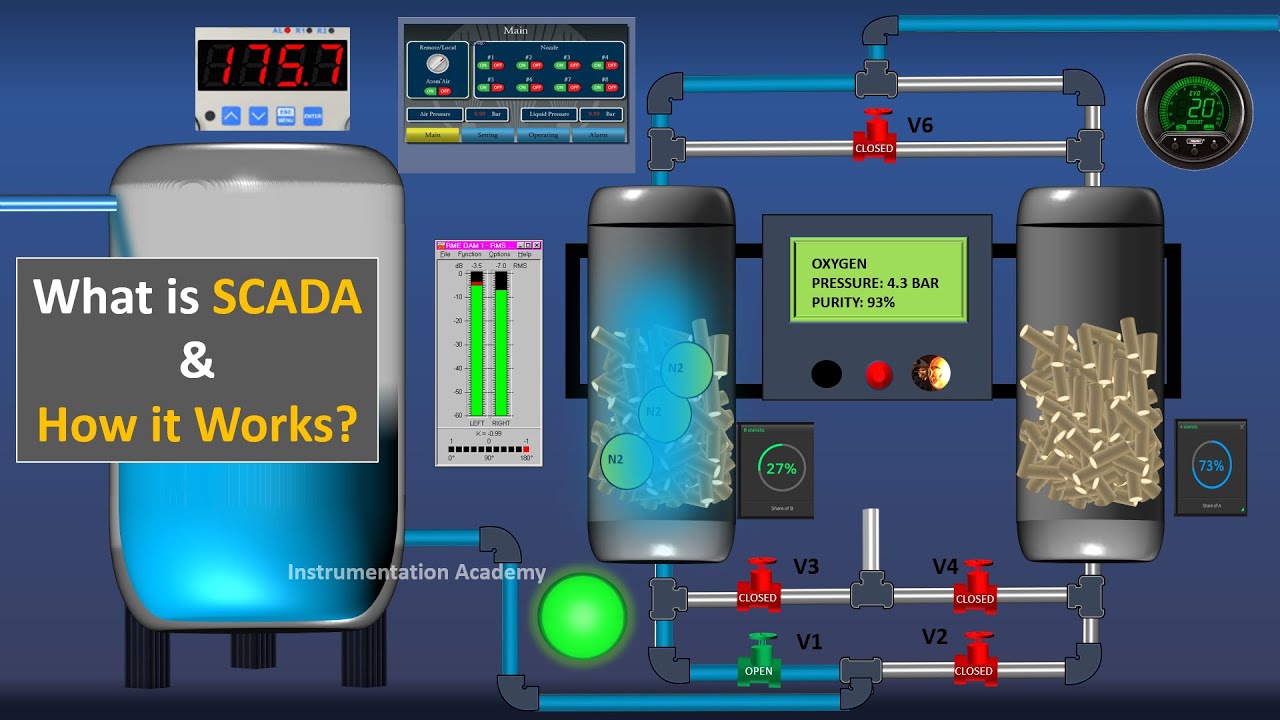

TLDRThis video from an industrial instrumentation course explores key characteristics and specifications of measurement and control instruments. It covers essential terms like range, accuracy, span, calibration, and tolerance, explaining how these affect the performance and calibration of instruments like manometers, thermometers, and pressure transmitters. The video emphasizes the importance of understanding these specifications to communicate effectively, perform calibration tasks, and maintain precise measurements in industrial settings. Viewers are encouraged to apply this knowledge to enhance their skills and understanding of instrumentation, with reference to industry standards like ANSI ISA S 5.1.

Takeaways

- 😀 Instrumentation plays a critical role in industrial processes, focusing on measurement and control specifications.

- 😀 Key specifications to understand include range, accuracy, type of signal, and sensor compatibility with controllers.

- 😀 Manufacturers provide specification sheets for each instrument, detailing factors like range, size, temperature, and sensor type.

- 😀 The 'range' refers to the limits within which an instrument can measure, both the maximum and minimum values.

- 😀 A transmitter’s range is often not displayed on the instrument, but found on its specification plate, unlike instruments like manometers.

- 😀 The 'span' refers to the difference between the upper and lower values in an instrument's range.

- 😀 Accuracy is a vital specification that defines how close an instrument’s reading is to the true value of the variable being measured.

- 😀 Accuracy can be expressed in percentage of range, span, or even in direct units of the variable measured.

- 😀 Knowing the accuracy helps when calibrating instruments and understanding the possible margin of error.

- 😀 Precision, unlike accuracy, refers to how consistent an instrument’s readings are, with high precision meaning low variability in repeated measurements.

- 😀 Tolerance is similar to accuracy but is typically based on an instrument's experience and operating conditions, rather than being listed in the specifications.

Q & A

What is the purpose of a specification sheet for measuring instruments?

-A specification sheet outlines the key features and characteristics of a measuring instrument, such as its range, accuracy, type of signal, and the sensors it can connect to. It helps users understand the instrument's capabilities and ensures proper use.

What information can typically be found on an instrument's specification sheet?

-Typical information on an instrument's specification sheet includes the range, size, pressure and temperature limits, sensor types, and other technical details essential for proper operation and calibration.

What does 'range' mean in the context of measuring instruments?

-The 'range' of an instrument refers to the set of values the instrument can measure, defined by its minimum and maximum limits. For example, a manometer may have a range from 0 to 21 kg/cm².

What is the difference between a manometer and a transmitter in terms of range?

-A manometer typically displays its range directly on its scale, while a transmitter's range is indicated on the device's plate, rather than on its screen. Additionally, the transmitter may have a calibration range distinct from its measurement range.

What is the 'span' of a measuring instrument?

-The 'span' (or 'range span') is the algebraic difference between the upper and lower values of an instrument's range. For example, if a thermometer has a range from 200°F to 1000°F, the span is 800°F.

Why is accuracy important for measuring instruments?

-Accuracy indicates how closely the instrument's readings match the true value of the measured variable. High accuracy ensures that the instrument provides reliable and truthful measurements, which is essential for proper process control and calibration.

How is accuracy typically expressed on a specification sheet?

-Accuracy is usually expressed as a percentage of the instrument's full scale, percentage of the span, or directly in the units of the measured variable. It may also be indicated as a percentage of the reading or as a fixed error margin.

What is the significance of understanding the accuracy of an instrument when calibrating it?

-Knowing the accuracy of an instrument allows the user to determine the acceptable error margin when comparing the instrument’s reading to a known reference. It ensures that the instrument operates within acceptable limits for its intended purpose.

What is the difference between tolerance and accuracy in measuring instruments?

-Accuracy refers to how closely an instrument's readings match the true value, while tolerance is the allowable variation in readings based on operational conditions or the instrument's experience. Tolerance is more flexible and often based on the specific context.

How do precision and accuracy differ in measuring instruments?

-Precision refers to the consistency of measurements taken with an instrument, meaning the readings are close to each other, while accuracy refers to how close the measurements are to the true value. An instrument can be precise but not accurate if it consistently provides incorrect measurements.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

5.0 / 5 (0 votes)