What is a PLC? (90 sec)

Summary

TLDRThis video explains the basics of a Programmable Logic Controller (PLC), highlighting its key components: Input, CPU, and Output. Using an example of a motor controlled by a push button, it demonstrates how a PLC processes input signals, runs them through the CPU, and delivers the output to control devices like motors. The video also touches on the importance of programming the PLC to perform specific tasks, such as turning a motor on or off with the press of a button. Viewers are encouraged to subscribe for more educational content.

Takeaways

- 🤖 A Programmable Logic Controller (PLC) is a special type of computer used to control industrial processes in fields like petroleum, steel, and automotive.

- 🖥️ Every PLC consists of three main parts: Input, CPU, and Output.

- 🔘 In an example with a motor and push button, the goal is to turn the motor on when the button is pressed and turn it off when pressed again.

- 📝 To achieve this, a program must be written and downloaded to the PLC's CPU.

- ⚙️ The input (button) sends an electrical signal to the PLC, which passes it to the CPU for processing.

- 🔄 The CPU cannot directly process raw electrical signals, so the input is converted into a format the CPU can handle.

- 📡 After processing, the CPU sends the output signal, which is converted back to an electrical signal to control the motor.

- 🔁 When the button is pressed again, the same process repeats, turning the motor off.

- 🎮 This process is similar to how a power button on a TV remote works.

- 📢 The video encourages viewers to subscribe for more educational content.

Q & A

What is a Programmable Logic Controller (PLC)?

-A Programmable Logic Controller (PLC) is a special type of computer designed to control industrial processes such as those in petroleum, steel, or automotive industries.

What are the three main components of a PLC?

-The three main components of a PLC are the Input, CPU, and Output.

What is the function of a PLC in the motor and push button example?

-In the motor and push button example, the PLC controls the motor by turning it on when the button is pressed and turning it off when the button is pressed again, similar to the power button on a TV remote.

What is the purpose of writing a program for the PLC?

-The purpose of writing a program is to instruct the PLC how to process the input signal (button press) and control the output (motor operation) based on the program logic.

Why does the input signal need to be converted before being sent to the CPU?

-The input signal needs to be converted into a format the CPU can process because the CPU cannot handle raw electrical signals directly.

What happens when the button is pressed in the described system?

-When the button is pressed, an electrical signal is sent to the PLC. The input component converts this signal, which is then processed by the CPU. The CPU sends instructions to the output, which turns on the motor.

What happens when the button is pressed again?

-When the button is pressed again, the same process repeats, and the motor is turned off.

How is the output signal processed to control the motor?

-The output component of the PLC converts the processed data back into a raw electrical signal and applies it to the motor, either turning it on or off based on the logic.

Why does the PLC need to convert signals at both the input and output stages?

-The PLC converts signals at the input stage so the CPU can process them, and at the output stage to send the appropriate electrical signals to control devices like the motor.

How does the example in the script compare to the power button on a TV remote?

-The motor and push button system in the example functions similarly to a TV remote's power button, where pressing the button alternately turns the motor (or TV) on or off.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

DASAR PEMOGRAMAN PLC - SIMBOL - SIMBOL DASAR PLC

PLC Learning Series - What are PLC Inputs?

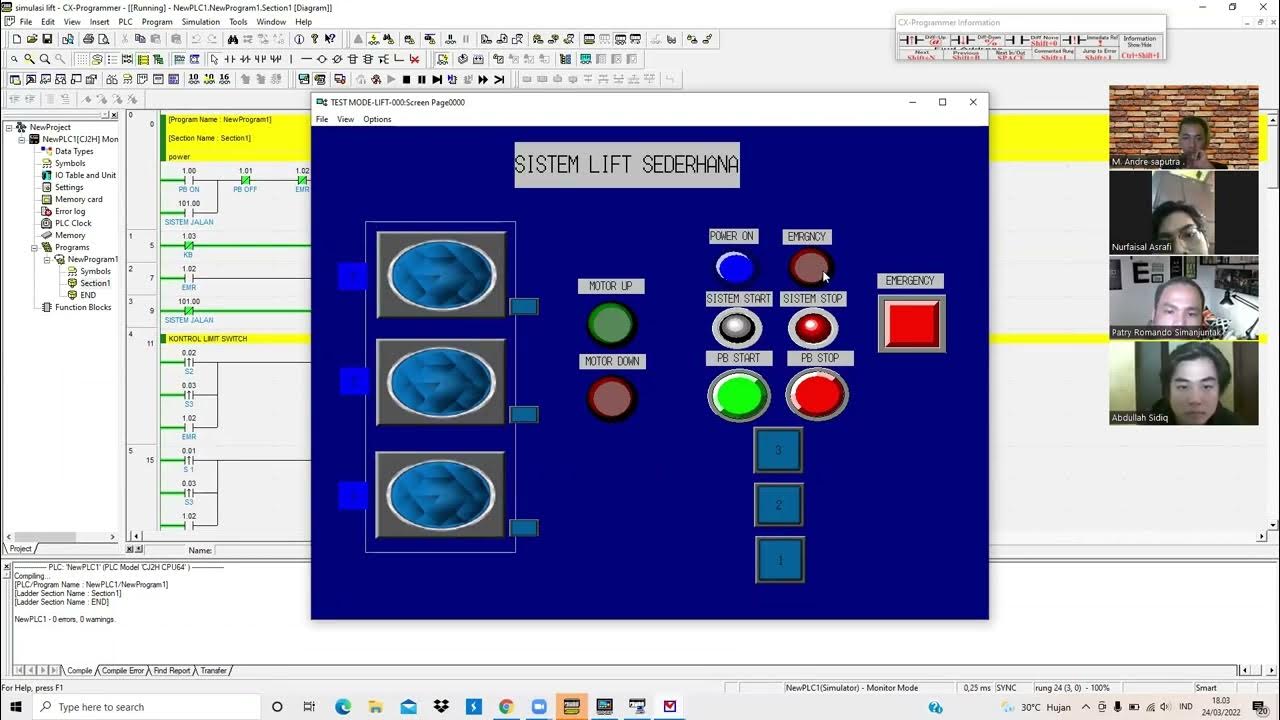

Simulasi Lift sederhana 3 Lantai dengan menggunakan PLC pada CX-Programmer dan CX-Designer

Source & Sink Concept in PLC । What is Sourcing & Sinking in PLC । PLC मैं Sink और Source कनेक्शन ?

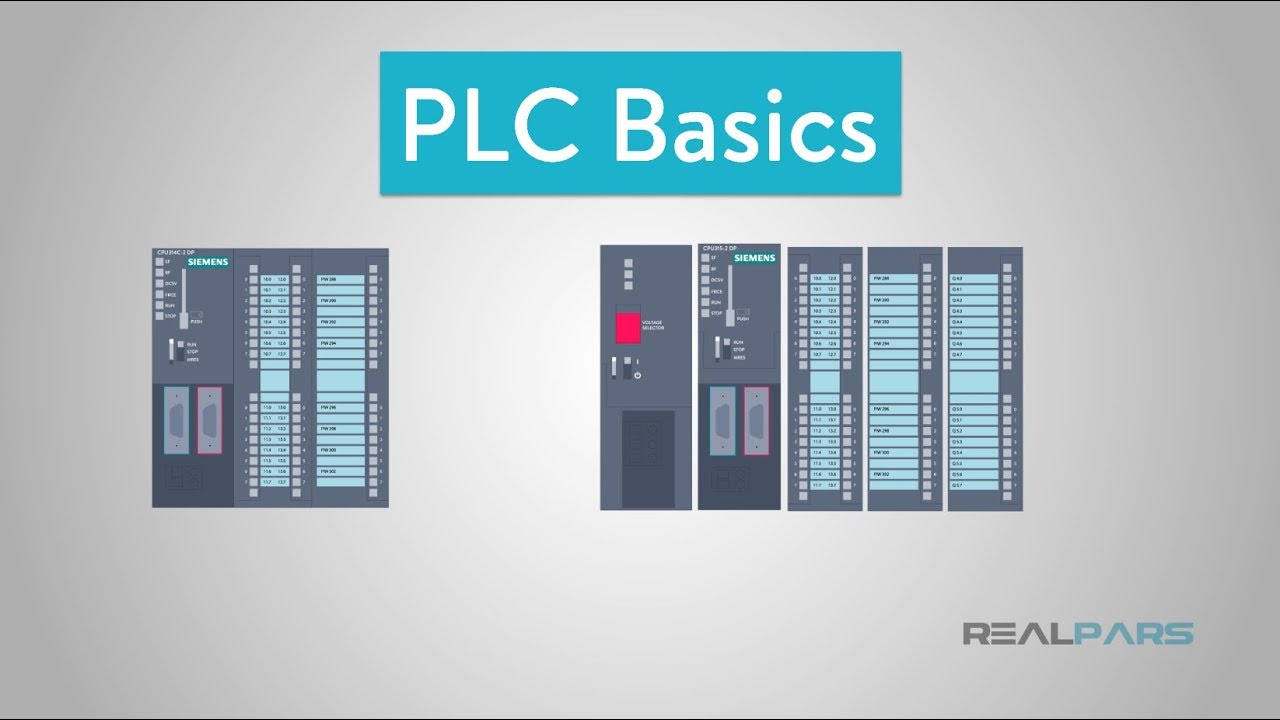

PLC Basics | Programmable Logic Controller

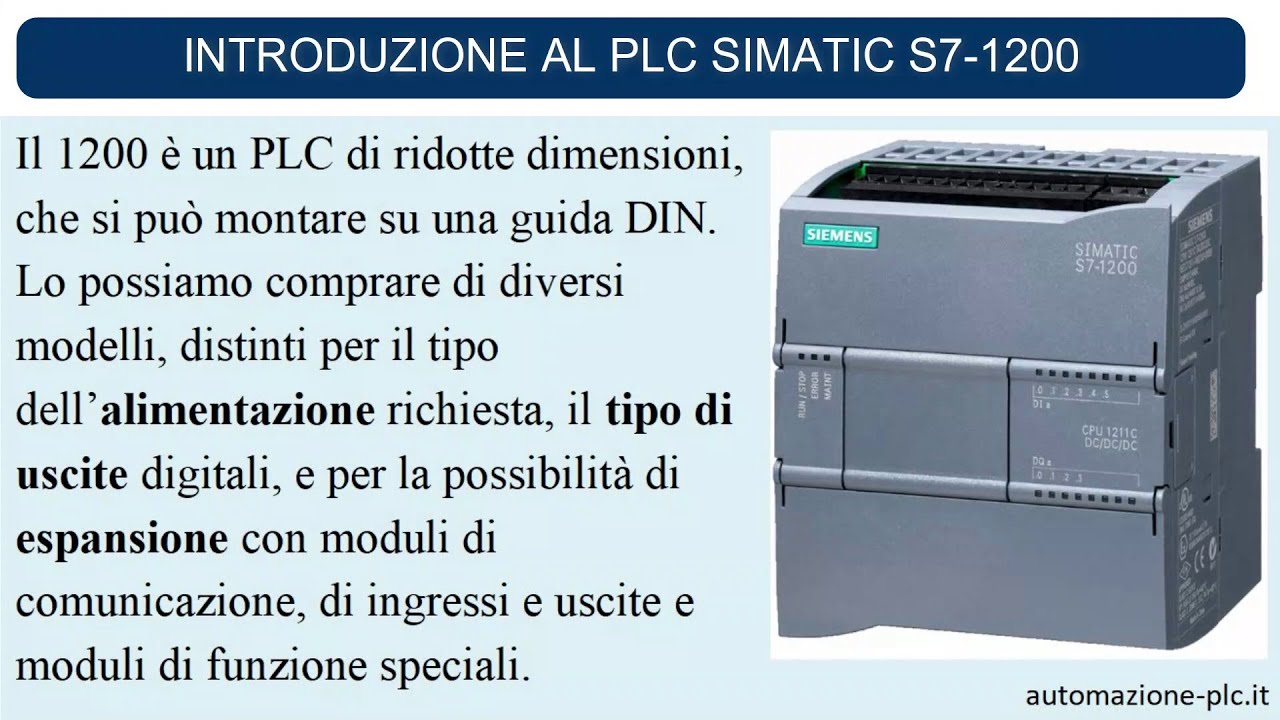

Introduzione al plc Simatic S7-1200 Siemens

5.0 / 5 (0 votes)