Introduzione al plc Simatic S7-1200 Siemens

Summary

TLDRThis video introduces Siemens' Simatic S7-1200 PLC, a compact programmable logic controller for small to medium installations. It covers the different models, power supply options, digital input/output configurations, and expansion capabilities, including communication modules and safety functions. The S7-1200 is noted for its cost-effectiveness and compatibility with the Siemens TIA Portal programming suite, which simplifies automation projects and enables advanced integration, including with Industry 4.0 standards like OPC-UA. The video highlights its flexibility, scalability, and integration with web-based monitoring and control systems.

Takeaways

- 🤖 The Siemens Simatic S7 1200 is a compact PLC designed for small to medium-sized installations, with various models available depending on power supply and output types.

- 🔧 The PLC 1200 can be expanded with communication, input/output, and special function modules, making it versatile for different applications.

- 📊 It belongs to the mid-range PLC category, positioned between micro PLCs like the Siemens LOGO and larger PLCs such as the Simatic S7 1500.

- ⚡ The 1200 PLC can be powered by 24V DC or 85-264V AC, with different models designed for specific power supply and output needs.

- 🛠️ The hardware offers scalability depending on the chosen CPU, ranging from the entry-level CPU 1211C to the high-performance CPU 1217C, which supports up to 8 additional modules.

- 🖥️ Programming the 1200 PLC is done using Siemens' TIA Portal, a powerful software suite used for larger PLCs, offering consistent programming practices across Siemens models.

- 💻 The S7 1200 can be programmed using ladder logic, function block diagrams, and structured text, offering flexibility for different programming preferences.

- 🌐 The PLC supports Ethernet communication via its onboard port, and additional modules can be installed for serial, Profibus, and wireless communications such as GPRS and LTE.

- 📈 The S7 1200 includes features like an integrated web server for monitoring and controlling variables via a web browser, and supports Industry 4.0 standards with secure OPC UA communication.

- 🔐 Some versions of the S7 1200 offer failsafe CPUs for safety applications, making it suitable for use in environments requiring higher security and reliability.

Q & A

What is the Siemens Simatic S7 1200 PLC and where does it fit in the market?

-The Siemens Simatic S7 1200 is a compact programmable logic controller (PLC) designed for small to medium installations. It fits into the category of compact PLCs, positioned between micro PLCs and larger, more powerful PLCs like the Simatic S7 1500 series.

What are the power supply options available for the S7 1200?

-The S7 1200 PLC is available with both DC and AC power supply options. For DC, it operates on 24V DC, while the AC version can handle voltages between 85V and 264V.

How can the outputs of the S7 1200 be configured?

-The outputs of the S7 1200 can be either static or relay-based. Static outputs work with direct current (DC), while relay outputs can control both DC and alternating current (AC) circuits.

What are the key differences between the various CPU models in the S7 1200 family?

-The CPUs range from the lower-end models like the 1211C and 1212C, which support fewer expansion modules, to the more advanced 1217C, which can accommodate up to 8 additional input/output modules.

What programming languages are supported by the S7 1200?

-The S7 1200 can be programmed using ladder logic, function block diagrams (FBD), and structured text (ST). These are common PLC programming languages, and Siemens refers to them as LAD, FUP, and SCL respectively.

Can the S7 1200 be expanded with additional modules?

-Yes, the S7 1200 supports various expansion modules, including digital and analog input/output modules, communication modules, and specialized function modules such as weighing and continuous monitoring systems.

How is the S7 1200 integrated with external networks and devices?

-The S7 1200 can connect to external devices using Ethernet, which is built into the PLC. It can also be expanded with additional communication modules for serial communication (RS232, RS485), Profibus, and even wireless communications via GPRS and LTE.

What role does TIA Portal play in the use of the S7 1200?

-The S7 1200 is programmed and configured within Siemens' TIA Portal software suite. This environment provides tools for designing, simulating, and monitoring automation systems, making it easier to integrate the S7 1200 with other Siemens products.

What are some notable features of the S7 1200's web server capabilities?

-The S7 1200 includes an integrated web server, allowing users to access and control the PLC via a web browser. This includes viewing and controlling variables, diagnosing issues, and accessing custom web pages, either on a local network or over the internet.

How does the S7 1200 fit into Industry 4.0 and modern communication standards?

-The S7 1200 supports the OPC UA protocol, which facilitates secure and standardized communication between devices in an Industry 4.0 environment. It also includes features like digital signatures and encryption for secure communication.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Überblick Siemens Simatic SPS Hardware - SPS programmieren lernen - Online Grundkurs (Kapitel 1.2)

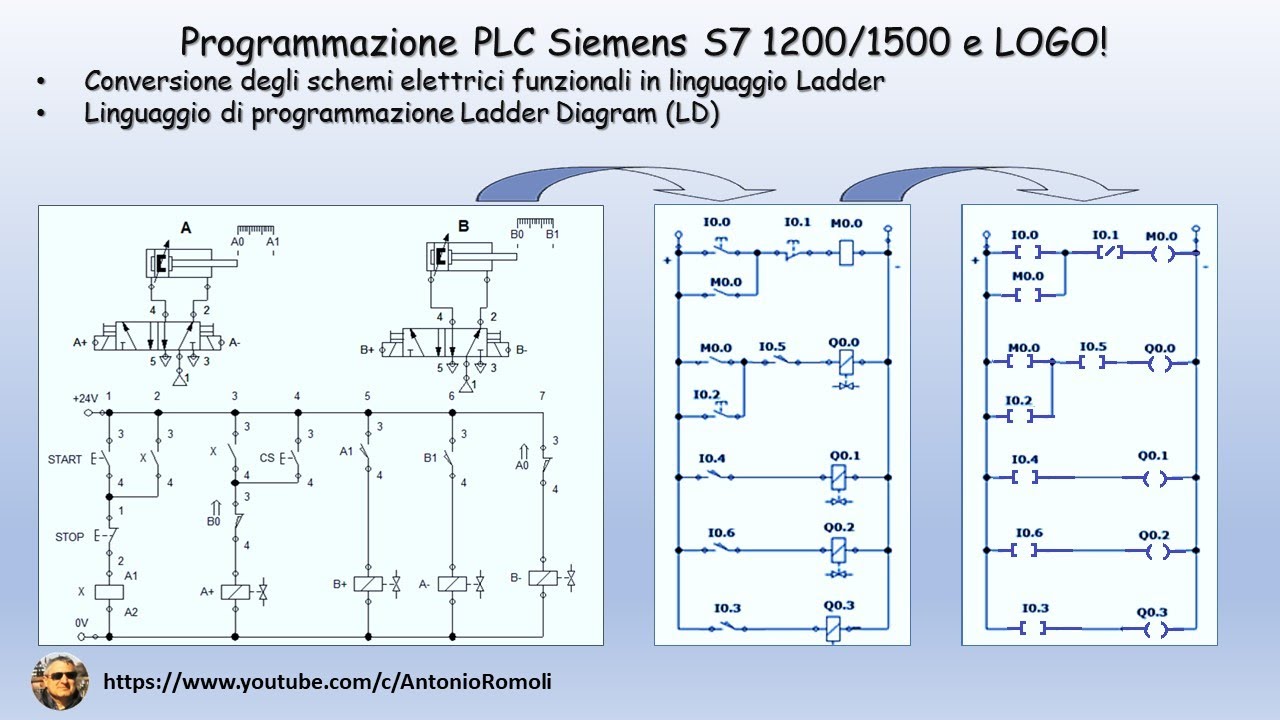

PLC: convertire lo schema elettrico funzionale in linguaggio di programmazione Ladder (Video 1.1)

Source & Sink Concept in PLC । What is Sourcing & Sinking in PLC । PLC मैं Sink और Source कनेक्शन ?

Example PLC: EATON EASY Intelligent Relay (Full Lecture)

DASAR PEMOGRAMAN PLC - SIMBOL - SIMBOL DASAR PLC

PLC SIEMENS S7 1200 - Montaje y Alimentación de CPU y módulos de expansión - Primeros Pasos

5.0 / 5 (0 votes)