#411 Ten Fluid Level (Water Level) Sensors and how to use them (Arduino, ESP32, ESP8266)

Summary

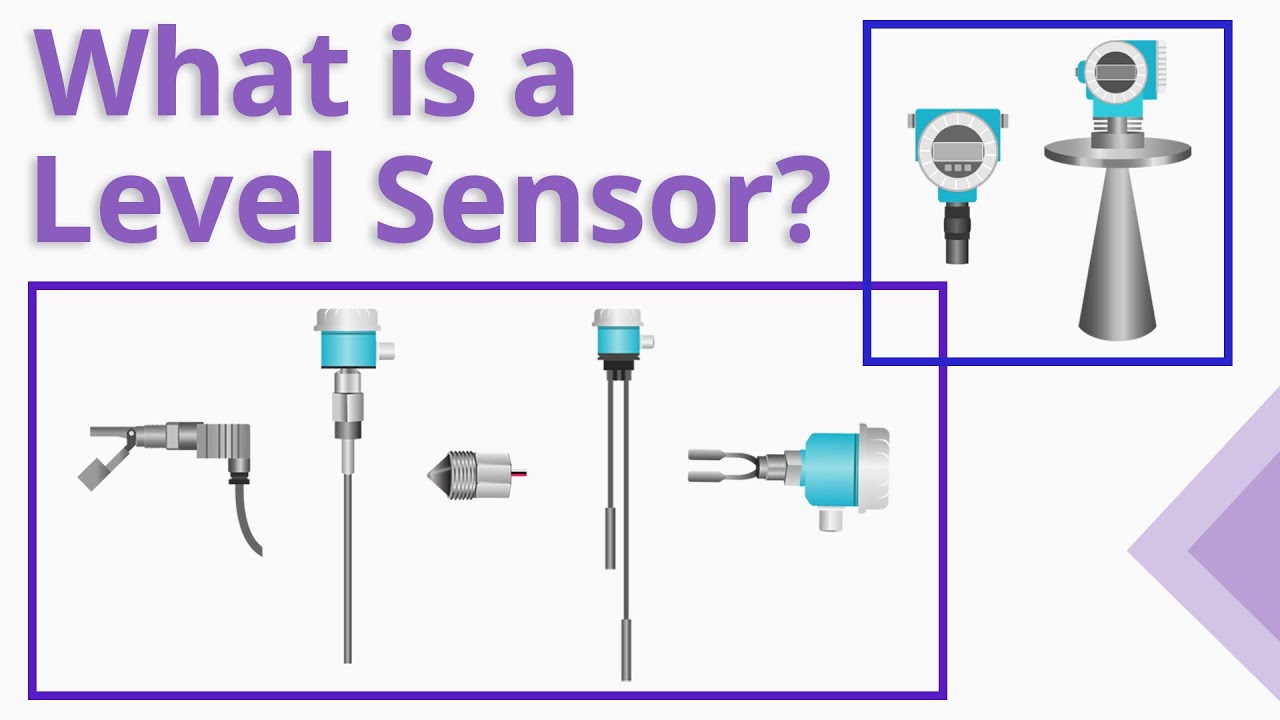

TLDRThis video explores various sensors for measuring liquid levels, from simple threshold sensors to advanced ultrasonic and pressure sensors. It discusses mechanical and electronic sensors, their mounting inside or outside tanks, and considerations for corrosion resistance and contamination. The video also covers different interfaces like open collector and current loop, and provides insights on connecting these sensors to microcontrollers. It's a comprehensive guide for those looking to monitor liquid levels in different applications.

Takeaways

- 🔍 The video discusses various methods and sensors for measuring liquid levels in different settings, such as home appliances, rural water tanks, and industrial chemical storage.

- 🏡 Two main motivations for the video are presented: monitoring liquid levels remotely in a cottage and avoiding coffee machine water shortages at home.

- 🔄 The video introduces 10 different types of sensors, including threshold sensors, distance sensors, and pressure sensors, each with their unique applications and mounting requirements.

- 🛠 Mechanical threshold sensors are explained, which work by making contact with the liquid and can be made of metal or plastic, raising concerns about corrosion and contamination.

- 📶 Electronic threshold sensors using capacitive or resistive methods are discussed, with an emphasis on their compatibility with plastic tanks and their open collector (OC) output.

- 💧 The importance of considering corrosion resistance and non-contamination when selecting sensors that come into direct contact with liquids is highlighted.

- 📊 For more precise liquid level measurement, the video covers distance sensors that use ultrasonic waves or laser light, and the challenges they face such as corrosion and signal reflection.

- 🔧 Pressure sensors are introduced as an indirect method to measure liquid levels by calculating the pressure at the bottom of a tank, with considerations for sensor placement and compatibility.

- ⚙️ The video also touches on the technical aspects of interfacing sensors with microcontrollers, including the use of resistors, voltage dividers, and analog-to-digital conversion.

- 🔗 The video concludes with a call to action for viewers to share their experiences with different sensors, emphasizing the value of collective knowledge in solving practical problems.

Q & A

What types of liquid level measurement sensors are discussed in the video?

-The video discusses sensors that react to fluid level thresholds, sensors that measure the exact fluid level, sensors mounted inside and outside of tanks, and sensors for the top and bottom of tanks.

What are threshold sensors, and how do they function?

-Threshold sensors detect when a particular fluid level is reached. They come in two types: mechanical switches or electronic sensors, which can use capacitive or resistive methods. They need to be in contact with the liquid to function.

What are the potential issues with mechanical sensors in liquid environments?

-Mechanical sensors can corrode when in contact with liquids, and their material may contaminate the liquid, particularly if they rust.

How do open collector (OC) outputs work and why are they beneficial?

-Open collector outputs allow the sensor's output voltage to be independent of the sensor’s supply voltage. By adding a resistor, the output can be controlled and customized, providing flexibility when dealing with varying voltage levels.

What are the differences between time-of-flight sensors using ultrasound and laser light?

-Ultrasound sensors use slower sound waves, while laser light sensors (often called LIDAR) use faster light waves. Both measure the distance between the sensor and the liquid surface, but are affected by factors like evaporation, pollution, and tank geometry.

How can pressure sensors be used to measure fluid levels?

-Pressure sensors measure the pressure at the bottom of the tank, which correlates to the liquid level based on the specific weight of the fluid. They need access to the tank's lowest point or can be placed directly in the fluid with a long cable.

What are the benefits of using current loop interfaces for long-cable sensors?

-Current loop interfaces are robust and efficient for sensors with long cables. They only require two wires to both power the sensor and transmit data, making them straightforward and reliable.

What measures can be taken to prevent sensor corrosion and contamination?

-Sensors that come into contact with liquids should be corrosion-resistant and not contaminate the tank’s contents. For internal sensors, materials must be selected carefully, especially in sensitive environments.

What is the advantage of reducing the number of sensor readings in systems where fluid levels don't change rapidly?

-By reducing the number of sensor readings, energy consumption is minimized, which is particularly important for electronic sensors that consume power while measuring. This can extend sensor and system longevity.

What mounting considerations should be taken into account for different sensor types?

-Different sensors require specific mounting locations. For example, time-of-flight sensors should be mounted on top of the tank to point towards the liquid surface, while pressure sensors must be mounted at the bottom or submerged.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级5.0 / 5 (0 votes)