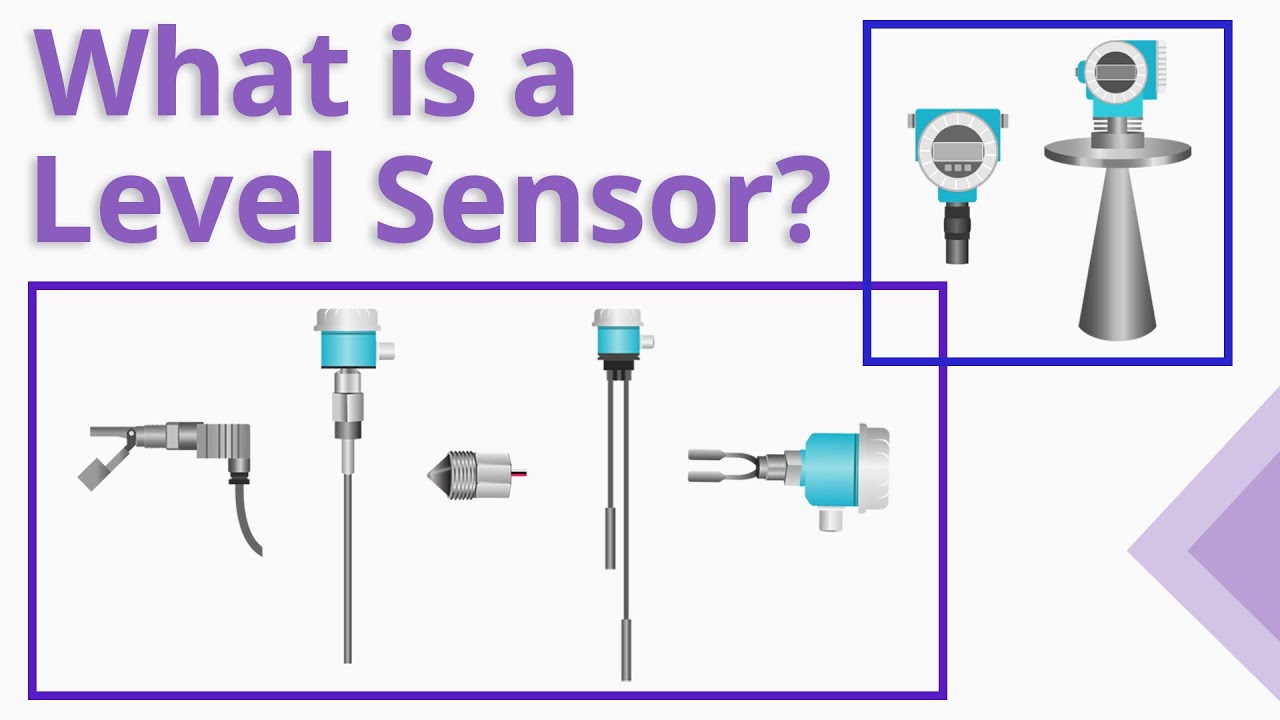

Level Sensors | Types of Level Sensors |Applications of Level Sensors

Summary

TLDRIn this video, Neeta's Communication Tutorial explores level sensors, crucial in various consumer and industrial applications. The tutorial covers two main types: point level sensors, which detect liquid presence at specific points, and continuous level sensors, which measure liquid levels continuously. Point level sensors include capacitance, optical, conductivity, vibrating, and float switch types, each with unique advantages and applications. Continuous level sensors encompass ultrasonic and radar types, known for their non-invasiveness and accuracy. The video provides insights into the working principles and ideal use cases for each sensor type, making it an informative resource for those in industries dealing with liquid, slurry, and granular material levels.

Takeaways

- 🔍 Level sensors are crucial in various industries for detecting the level of liquids, fluids, and fluidized solids.

- 📊 They are categorized into point level measurement and continuous level measurement, each serving different monitoring needs.

- 📛 Point level sensors indicate presence at a specific point, whereas continuous level sensors track the level as it changes.

- 🌊 Capacitive sensors use an electric field affected by the dielectric constant of the liquid to measure level.

- 💡 Optical sensors function by reflecting light from a cone-shaped tip, which changes state when submerged.

- 💧 Conductivity sensors rely on the electric current flow through conductive liquids to signal level changes.

- 🔊 Vibrating fork sensors detect level by measuring changes in the oscillation frequency of a piezo ceramic crystal.

- 🔄 Float switches use a mechanical float to indicate level by opening or closing an electrical circuit.

- 📈 Ultrasonic sensors measure level by timing the echo of emitted sound waves, unaffected by material properties.

- 📡 Radar sensors use microwaves to determine level, offering accuracy without contact and resistance to environmental factors.

Q & A

What are level sensors and why are they important?

-Level sensors are devices that detect the level of liquids, fluids, and fluidized solids, including slurries, granular materials, and powders. They play a crucial role in a variety of consumer and industrial applications by ensuring the correct amount of liquid or material is present in a given process or container.

What are the two main types of level sensors discussed in the script?

-The two main types of level sensors discussed are point level measurement and continuous level measurement. Point level measurement indicates when a product is present at a certain point, while continuous level measurement indicates the continuous level of a product as it rises or falls.

How do capacitive level sensors work?

-Capacitive level sensors work by giving off an electric field and detecting the level by the effect of its electric field. They use a probe to check changes in the level, which are then converted into analog signals. The principle is based on the capacitance equation where capacitance is directly proportional to the permittivity of the liquid.

What are the advantages of using optical level sensors?

-Optical level sensors have the advantage of being non-invasive and providing a direct indication of the level. They work by converting light rays into electrical signals, which measure the physical quantity of light and translate it into a measurement.

How do conductivity type level sensors operate?

-Conductivity level sensors operate on the principle that most liquids conduct electricity. They use a probe with a pair of electrodes, and when the liquid covers the probe, it forms an electric circuit, causing current to flow and signaling the level.

What are the benefits of using vibrating or tuning fork type level sensors?

-Vibrating or tuning fork type level sensors are cost-effective, compact, easy to install, and maintenance-free. They operate by detecting changes in the frequency of a piezo ceramic crystal as the level changes.

How does a float switch work as a point level sensor?

-A float switch works by using a float that raises or lowers when a product is applied or removed, which in turn opens or closes a circuit as the level raises or lowers. This movement provides an indication for high or low levels.

What is the principle behind ultrasonic level sensors?

-Ultrasonic level sensors work by emitting and receiving ultrasonic waves. The time it takes for the waves to reflect back is used to measure the distance to the liquid surface, indicating the level.

How do radar level sensors measure the level of a product?

-Radar level sensors transmit microwaves using an antenna. The product reflects the microwaves back to the antenna, and the time from emission to reception of the signal is proportional to the level of the product. The level in the tank is calculated by subtracting the distance between the sensor and the liquid surface from the height of the radar level sensor.

What are the applications of level sensors in various industries?

-Level sensors are used in a variety of industries, including automobile, oil manufacturing, water treatment, chemical industries, and many others. They ensure proper levels of liquids or materials are maintained for efficient and safe operations.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Temperature Sensor || Type, Application And Advantage Of Temperature Sensor.

Humidity Sensors | Hygrometers | Humidity Parameters|Types of Humidity Sensors |Applications

Pressure Sensor || Working of pressure sensor || Types and application of pressure sensor

What is a Pressure Sensor?

What is a Level Sensor?

Unit I Introduction to Mechatronics, Sensors and Actuators

5.0 / 5 (0 votes)