Pulp and Paper (5) Bleaching

Summary

TLDRThis video explains the processes involved in pulping and bleaching wood fibers for paper production. It contrasts chemical and mechanical pulping, highlighting their effects on lignin content and paper quality. Chemical pulping removes most lignin for high-quality, white paper, while mechanical pulping leaves lignin intact, resulting in stiff, brown fibers for lower-grade papers. The video also explores two bleaching methods: lignin removal for permanent brightness, and lignin masking for short-term whitening. Ultimately, it emphasizes the necessity of virgin fibers from forestry to sustain the paper cycle, as recycled fibers degrade over time.

Takeaways

- 😀 Chemical pulping leaves residual lignin in the paper fiber, while mechanical pulping retains most of the lignin.

- 😀 Chemical pulping results in stronger, cleaner paper but requires some lignin to remain to avoid damaging cellulose.

- 😀 Mechanical pulping produces stiff fibers but makes the paper brown, which is unappealing for high-quality uses.

- 😀 Bleaching is required to improve the whiteness of paper and deal with the residual lignin content.

- 😀 There are two main types of bleaching: lignin removal (permanent effect) and lignin masking (temporary effect).

- 😀 Lignin removal bleaching is used for high-quality paper such as magazines and office papers.

- 😀 Lignin masking bleaching is cheaper and often used for short-lived papers like newspapers and pulp novels.

- 😀 Chlorine dioxide and hydrogen peroxide are common chemicals used for bleaching, with chlorine use declining due to environmental concerns.

- 😀 High-end paper requires chemical pulp with lignin removal, while lower-end paper uses mechanical pulp with lignin masking.

- 😀 The recycling of paper fibers leads to fiber degradation over time, necessitating virgin fiber input to maintain quality in the paper cycle.

- 😀 The paper fiber lifecycle involves various stages, from high-quality paper to downcycled products like tissue or insulation, before being incinerated or recycled.

Q & A

What is the main difference between chemical pulping and mechanical pulping?

-Chemical pulping removes a significant portion of lignin while preserving cellulose, resulting in strong fibers suitable for high-quality paper. Mechanical pulping retains most of the lignin, producing stiff, brown fibers used for lower-quality paper.

Why is bleaching necessary in the paper production process?

-Bleaching is necessary to remove or chemically alter residual lignin in the pulp, which improves the whiteness and appearance of the paper.

What are the two main types of bleaching, and how do they differ?

-The two main types are lignin removal bleaching, which dissolves lignin and permanently increases brightness, and lignin masking bleaching, which chemically alters lignin without removing it, causing paper to eventually turn brown.

Which type of paper typically uses lignin masking bleaching and why?

-Short-life papers such as newspapers and pulp paperbacks use lignin masking bleaching because it is cheaper and faster, and these papers are expected to have a limited lifespan before recycling.

Why is lignin removal bleaching preferred for high-grade papers?

-High-grade papers, such as magazine and office papers, require very white, smooth, and strong paper, which is achieved by removing lignin entirely through chemical pulping and lignin removal bleaching.

Can recycled fibers be used indefinitely in paper production?

-No, recycled fibers degrade over time through downcycling, reducing their quality. Virgin fiber input is essential to maintain the paper quality and ensure a sustainable paper cycle.

What environmental concerns have affected the choice of bleaching chemicals?

-Chlorine bleaching has become less common due to environmental concerns. Alternatives like chlorine dioxide and hydrogen peroxide are now more widely used.

What happens to paper fibers at the end of their lifecycle?

-At the end of their lifecycle, degraded paper fibers are either incinerated for energy recovery or repurposed into products like insulation materials.

Why is it necessary to maintain a forestry cycle in paper production?

-Forestry cycles, including felling and replanting trees, are necessary to provide a continuous supply of virgin fibers, which are crucial for sustaining paper quality and the overall paper production system.

How does lignin content affect the physical properties of paper?

-High lignin content makes fibers stiff and brown, affecting paper appearance and texture. Reducing or masking lignin improves whiteness and can make the paper smoother and more flexible depending on the pulping and bleaching method used.

What is downcycling in the context of paper production?

-Downcycling refers to the gradual degradation of paper fibers through repeated recycling, which reduces their strength and quality, limiting their reuse in high-grade paper products.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

From Tree to Sheet: How Paper Is Made | Unveiling the Manufacturing Process

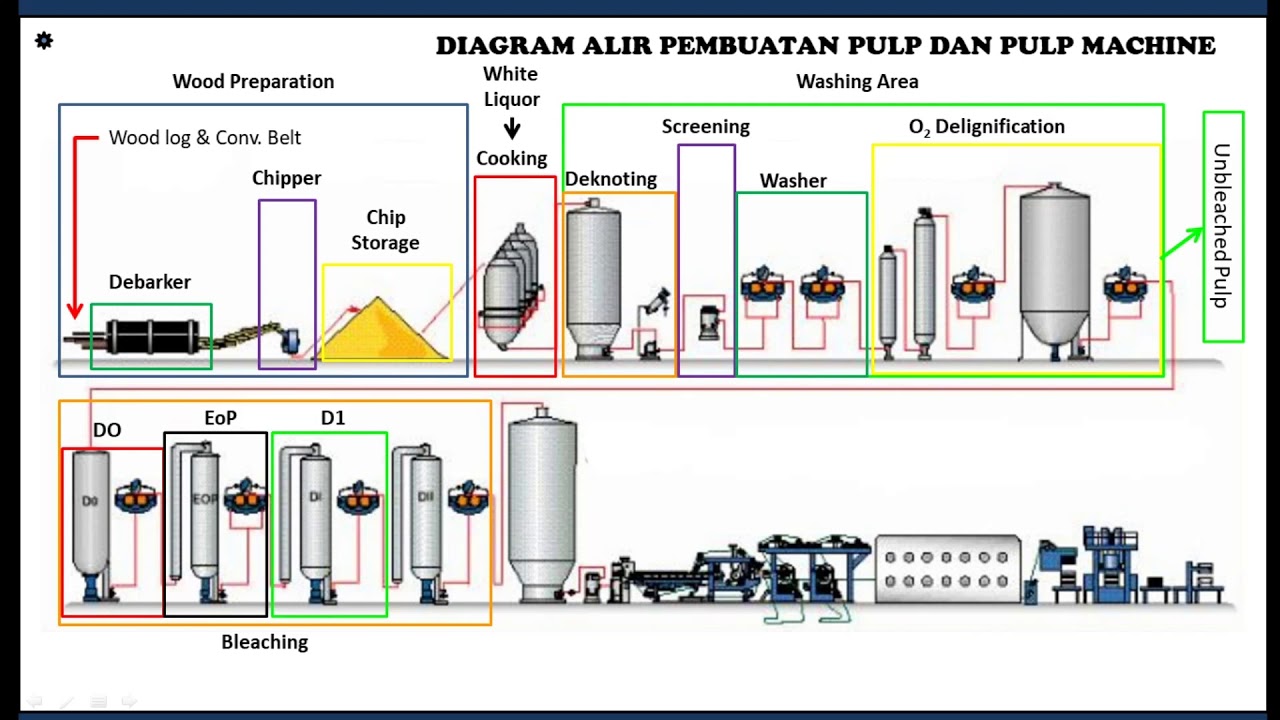

Pembuatan PULP dan KERTAS - Diagram Alir Proses

1. Overview Proses Pembuatan Kertas (Paper Making Process Overview)

How is PAPER Made from WOOD? Amazing Paper Production Factory!

Kimia Industri - Pembuatan Pulp dan Kertas (Diagram Alir proses) (Bag. 2 - Akhir)

Level 2 Papermaking - Bleaching

5.0 / 5 (0 votes)