Pembuatan PULP dan KERTAS - Diagram Alir Proses

Summary

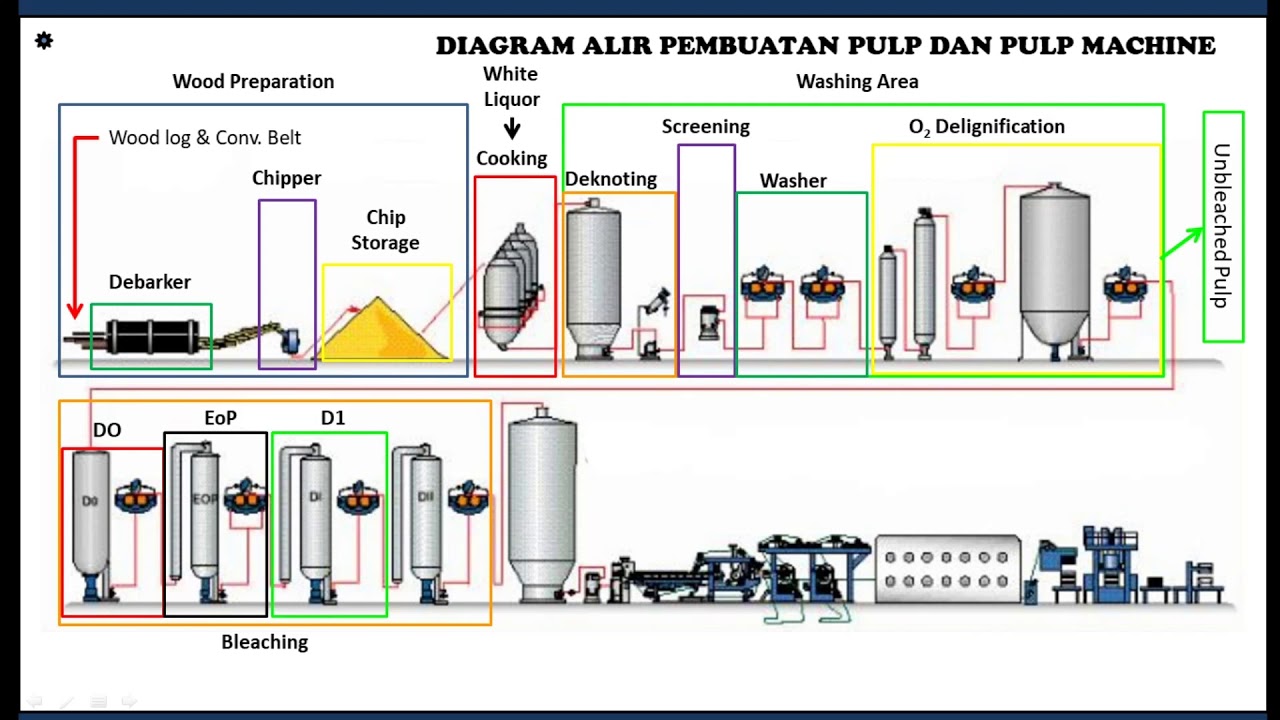

TLDRThis video explains the intricate process of pulp and paper production, focusing on the steps involved in creating paper from raw materials. It covers the separation of fibers, the delignification process, and the chemical treatments required to achieve high-quality paper. The script also highlights the importance of using specific chemicals like sodium hydroxide and chlorine for bleaching, and how waste products like Black Liquor are recycled to generate energy. The entire process emphasizes the chemical and mechanical methods used to produce paper, ensuring both quality and sustainability in paper manufacturing.

Takeaways

- 😀 The script begins with a greeting and introduction to the topic of pulp and paper manufacturing in the chemical engineering field.

- 😀 Pulp is created by separating fibers from raw materials, primarily consisting of cellulose and hemicellulose.

- 😀 The process of paper manufacturing involves compressing these fibers under pressure to create thin sheets of paper.

- 😀 The raw materials, like wood, contain lignin which must be removed to produce high-quality paper with a bright, white finish.

- 😀 Three methods for producing paper pulp are discussed: mechanical, chemical, and combined chemical-mechanical processes.

- 😀 The 'digester' is a key machine where wood chips are cooked to remove lignin and produce pulp.

- 😀 The chemical process of delignification uses white liquor (a mix of chemicals like sodium hydroxide and sodium sulfide) to break down lignin during cooking.

- 😀 After delignification, the paper pulp is separated from the black liquor (the waste byproduct containing lignin and other chemicals).

- 😀 The black liquor is processed for energy recovery and chemical recovery, turning waste into steam to generate electricity for the factory.

- 😀 Bleaching agents like chlorine, hydrogen peroxide, and ozone are used to whiten the paper pulp and achieve the desired brightness before it is dried and converted into finished paper.

Q & A

What is the first step in the pulp and paper manufacturing process?

-The first step is harvesting wood from industrial plantations, which typically involve monoculture forests designed for specific industries, like Acacia for paper production.

Why is delignification important in paper manufacturing?

-Delignification is crucial because lignin, which is present in wood, causes the paper to appear dark. Removing lignin makes the paper lighter and of higher quality.

What chemicals are used in the delignification process during pulping?

-Chemicals such as sodium hydroxide (NaOH), sodium sulfide, and sodium carbonate are used to break down lignin in the wood during the cooking process.

What is 'black liquor' and why is it significant in the pulp and paper industry?

-'Black liquor' is a byproduct of the delignification process. It contains organic material from lignin and other chemicals used during pulping. It is significant because it can be reused to generate energy and recover valuable chemicals like sodium hydroxide.

What is the role of the 'boiler' in the pulp and paper process?

-The boiler is used to generate steam from black liquor, which helps in powering turbines and also recycles energy to support the pulping process.

How is the waste from the pulp and paper process reused for energy production?

-The black liquor, which contains both organic and inorganic solids, is burned in the boiler to generate steam. This steam is then used to drive turbines, producing electricity that can power the entire mill.

What is the purpose of the 'digester' in pulp manufacturing?

-The digester is a large vessel where wood chips are cooked at high pressure and temperature with chemicals to remove lignin, separating cellulose fibers for the pulp.

How is 'bleaching' used in the paper-making process?

-Bleaching is used to further refine the pulp by removing any remaining impurities and lignin, resulting in a brighter and whiter paper. Chemicals like chlorine, hydrogen peroxide, and ozone are often used in this stage.

What types of paper can be produced from the pulp manufactured in this process?

-The pulp can be used to produce various types of paper, including packaging paper, tissue paper, cigarette paper, and different grades of cardboard, depending on the intended use.

What environmental considerations are associated with the pulp and paper manufacturing process?

-The process generates waste products like black liquor and water waste from the bleaching process. However, efforts like the recovery of black liquor for energy generation and chemical recycling help mitigate environmental impact.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

SERING PAKE, TAPI GAK TAU PROSESNYA? TERNYATA BEGINI TAHAP PEMBUATAN KERTAS DARI AWAL HINGGA AKHIR

Kimia Industri - Pembuatan Pulp dan Kertas (Diagram Alir proses) (Bag. 2 - Akhir)

How Paper Is Made

1. Overview Proses Pembuatan Kertas (Paper Making Process Overview)

JARANG ORANG TAHU, BEGINI PROSES PEMBUATAN BENDA-BENDA DISEKITAR KITA.

PRODUCTION PROCESS FOR MAKING FACIAL TISSUE at the FACTORY FROM RECYCLED OFFICE PAPER MATERIALS

5.0 / 5 (0 votes)