Yield Strength and Resilience of Materials | Basic Concepts | Materials Science And Engineering

Summary

TLDRIn this engineering tutorial, the video delves into the properties of materials, focusing on yield strength and resilience. It explains how these properties relate to the stress-strain curve of materials, covering the transition from linear elastic to non-linear plastic regions. The video also explores the concept of resilience, which is the material's ability to absorb and recover energy under elastic deformation. Key methods for determining yield strength are highlighted, along with the modulus of resilience for various materials like aluminum, copper, and steel. The tutorial provides a clear understanding of these concepts in material science.

Takeaways

- 😀 The video discusses the properties of materials, focusing on yield strength and resilience.

- 😀 Yield strength is the stress at which a material transitions from elastic to plastic behavior.

- 😀 Materials undergo both elastic (reversible) and plastic (permanent) deformations under tensile stress.

- 😀 The stress-strain curve consists of a linear elastic region (OM) and a non-linear plastic region (NPQ).

- 😀 The transition point between elastic and plastic behavior is called **yielding**, marked by the yield strength.

- 😀 Yield strength is determined using the **0.2% offset method**, which involves drawing a parallel line to the elastic portion of the curve and determining where it intersects the stress-strain curve.

- 😀 Different materials have different yield strength values; for example, aluminum has 35 MPa, steel has 180 MPa.

- 😀 Resilience is the ability of a material to absorb energy in the elastic region and recover it after unloading.

- 😀 The modulus of resilience quantifies the energy a material can store elastically before yielding.

- 😀 The modulus of resilience is calculated by integrating the stress-strain curve from 0 to the yield strain, i.e., over the linear elastic region.

- 😀 Understanding yield strength and resilience helps in material selection and design, as these properties dictate a material's response to stress.

Q & A

What are the two main types of deformation that materials undergo during a tensile test?

-Materials exhibit elastic deformation, where they return to their original shape after stress removal, and plastic deformation, where they permanently deform and do not return to their original shape.

Define yield strength in materials science.

-Yield strength is the stress at which a material transitions from elastic behavior to plastic behavior during a tensile test.

What is yielding and how is it related to the stress-strain curve?

-Yielding is the phenomenon where a material transitions from the linear elastic region to the non-linear plastic region on the stress-strain curve.

Why is it difficult to locate the exact yield point for most materials?

-Different materials have varying stress-strain characteristics, making the transition from elastic to plastic behavior gradual rather than sharply defined.

Explain the 0.2% offset method for determining yield strength.

-The 0.2% offset method involves drawing a line parallel to the linear elastic region of the stress-strain curve but offset along the strain axis by 0.002. The intersection of this line with the stress-strain curve gives the yield strength.

List the approximate yield strength values (in MPa) for aluminium, copper, iron, steel, and brass.

-Aluminium: 35 MPa, Copper: 69 MPa, Iron: 130 MPa, Steel: 180 MPa, Brass: 75 MPa.

Define resilience in the context of material properties.

-Resilience is the capacity of a material to absorb energy when deformed elastically and release it upon unloading.

How is the modulus of resilience calculated from the stress-strain curve?

-The modulus of resilience (Ur) is calculated as the area under the stress-strain curve in the linear elastic region, given by the integral Ur = ∫₀^εy σ dε, where εy is the yield strain.

Which part of the stress-strain curve represents elastic behavior, and which part represents plastic behavior?

-The linear portion up to point N or P represents elastic behavior, while the non-linear portion beyond this point represents plastic behavior.

Why is resilience only concerned with the elastic region of a material?

-Resilience measures the energy that can be recovered after deformation, which is only possible in the elastic region; in the plastic region, deformation is permanent and energy is not fully recoverable.

How does the stress-strain behavior vary among different materials?

-Different materials exhibit varying stress-strain characteristics; some may fracture before reaching the plastic region, while others show distinct upper and lower yield points, making the stress-strain curve unique for each material.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

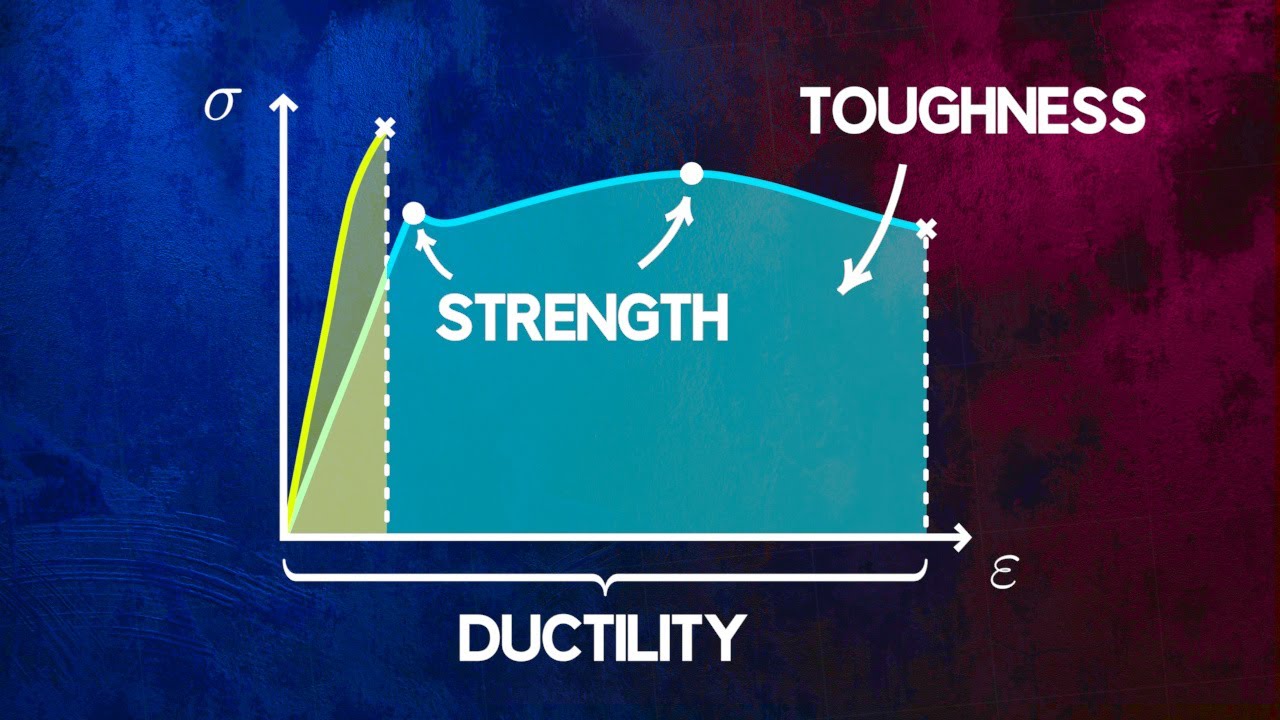

Understanding Material Strength, Ductility and Toughness

stress strain curve explained with tensile test.

Diagramma della prova di trazione carichi-allungamenti @meccanicando

Reaching Breaking Point: Materials, Stresses, & Toughness: Crash Course Engineering #18

EVERYTHING on Axial Loading Normal Stress in 10 MINUTES - Mechanics of Materials

Stress and Strain | Stress strain curve of mild steel | Mechanical Properties of Solids |

5.0 / 5 (0 votes)