What is SCADA? Supervisory Control and Data Acquisition

Summary

TLDRThis video provides an insightful overview of SCADA (Supervisory Control and Data Acquisition) systems in industrial automation. It highlights the essential components, including sensors, field controllers, and supervisory computers, and explains how SCADA systems enable real-time data monitoring, process control, and remote operation. Key functionalities such as data acquisition, communication, alarm management, and control commands are discussed. The video also covers SCADA's features, security concerns, and advantages in reducing downtime and operational costs, making it a vital tool for managing complex industrial processes efficiently.

Takeaways

- 😀 SCADA systems combine both hardware and software to manage industrial operations efficiently.

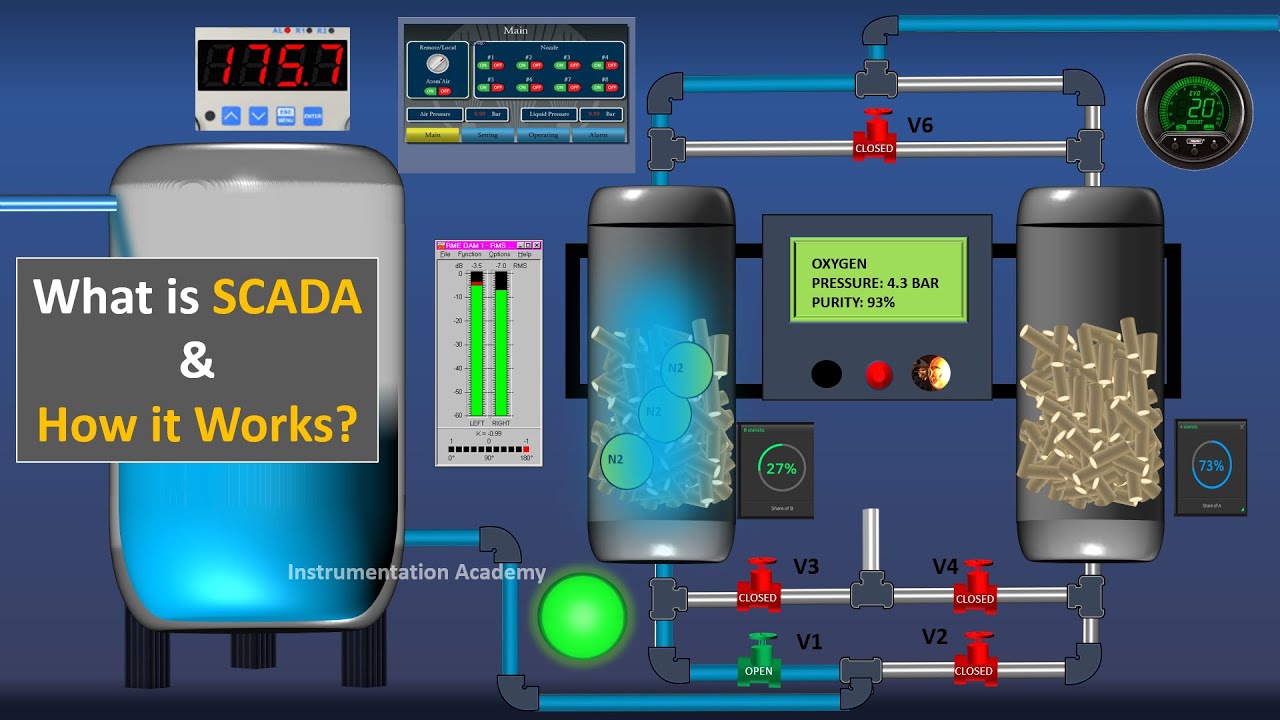

- 😀 SCADA allows real-time data visualization for processes like pipeline flow rates and valve positions.

- 😀 SCADA is essential for maintaining safety, ensuring measurements remain within specified ranges to prevent dangerous situations.

- 😀 SCADA enables remote monitoring and control, even if industrial sites are far from the central control center.

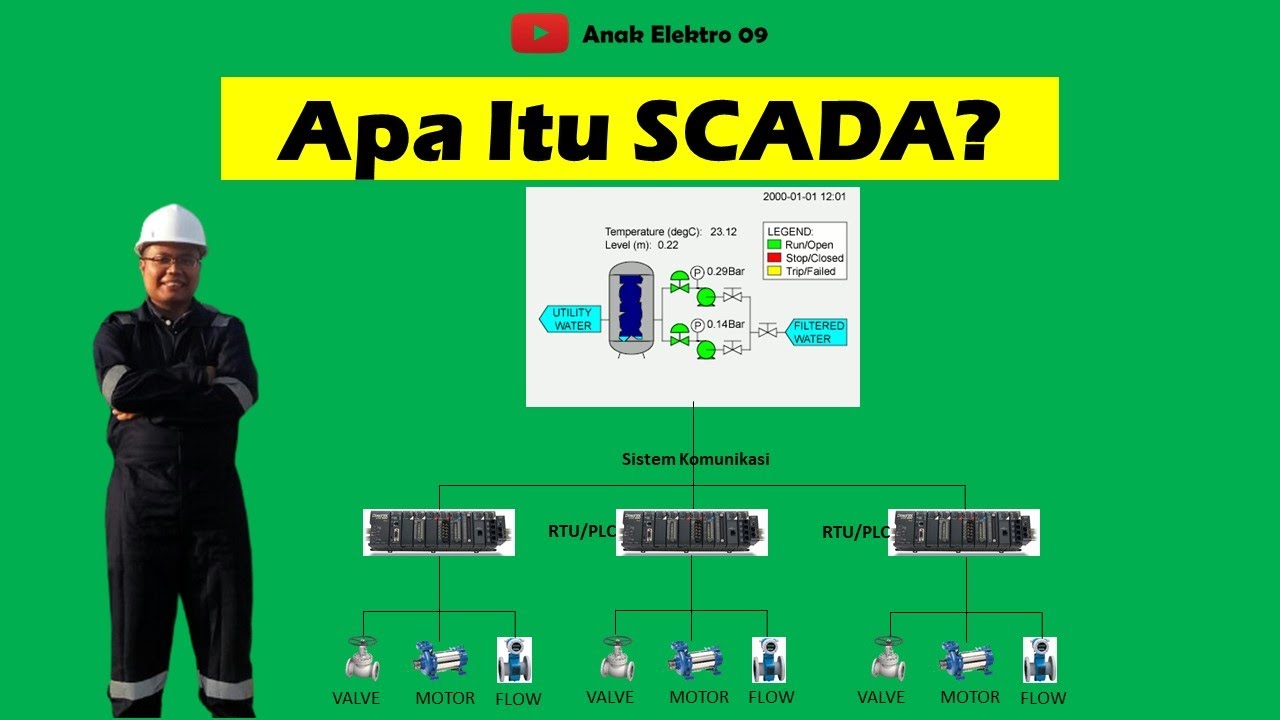

- 😀 The SCADA architecture consists of multiple levels, from field devices to supervisory computers and mobile interfaces.

- 😀 Data acquisition in SCADA starts with sensors and field controllers that gather and transmit operational data.

- 😀 SCADA systems use protocols like DNP3, Modbus, and SMP for secure and reliable data communication.

- 😀 The SCADA supervisory computer presents data in graphical formats, making it easy for operators to monitor and make decisions.

- 😀 SCADA systems include features for alarm detection and control actions, either manual or automatic, based on operator input or system programming.

- 😀 SCADA systems help prevent downtime by predicting potential failures and sending alerts to operators to take timely actions.

Q & A

What is the purpose of a SCADA system in industrial operations?

-A SCADA system is used for controlling and monitoring industrial processes, providing real-time data to operators and ensuring the smooth functioning of equipment across plants. It helps to reduce overhead costs and minimize system errors.

What are the key components of a SCADA system?

-The main components of a SCADA system include field devices (sensors and actuators), field controllers (RTUs and PLCs), a control center with a SCADA server, SQL databases, HMI (Human-Machine Interface) software, and supervisory computers.

Why is real-time data visualization important in SCADA systems?

-Real-time data visualization is crucial because it allows operators to monitor and control processes in real-time, ensuring safety, accuracy, and efficient operations. It helps track parameters like flow rates and control valve positions across the plant.

How does SCADA ensure safety in industrial environments?

-SCADA systems are designed to monitor measurement parameters and ensure they remain within safe ranges. If parameters go beyond predefined thresholds, the system triggers alarms and notifications to prevent dangerous situations.

What is the role of mobile HMI in SCADA systems?

-Mobile HMI allows operators to access real-time data and control industrial processes remotely. It enables the monitoring of plant operations even when operators are away from the control center.

What is the difference between manual and automatic control in SCADA systems?

-Manual control involves operators making decisions and issuing control commands based on the data displayed on the SCADA system. Automatic control, on the other hand, allows the system to take predefined actions automatically when alarm conditions are met.

How does SCADA support predictive maintenance?

-SCADA systems use historical data to identify trends, allowing operators to predict potential failures before they occur. This enables timely intervention, reducing downtime and preventing costly disruptions.

What are the communication protocols used in SCADA systems?

-SCADA systems typically use protocols such as DNP3, Modbus, and SMP for vertical and horizontal data transmission. These protocols ensure reliable communication between field devices, controllers, and supervisory systems.

How does redundancy improve SCADA system reliability?

-Redundant servers in SCADA systems ensure continuous monitoring and control in case of failures. If the primary server fails, a backup server takes over, minimizing downtime and ensuring system integrity.

What are the security concerns with SCADA systems?

-SCADA systems are vulnerable to unauthorized access due to their reliance on open technologies. This can lead to potential security breaches where attackers could send commands to field devices, corrupting plant processes. For sensitive environments, additional security measures are recommended.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

5.0 / 5 (0 votes)