Introduction To SCADA System

Summary

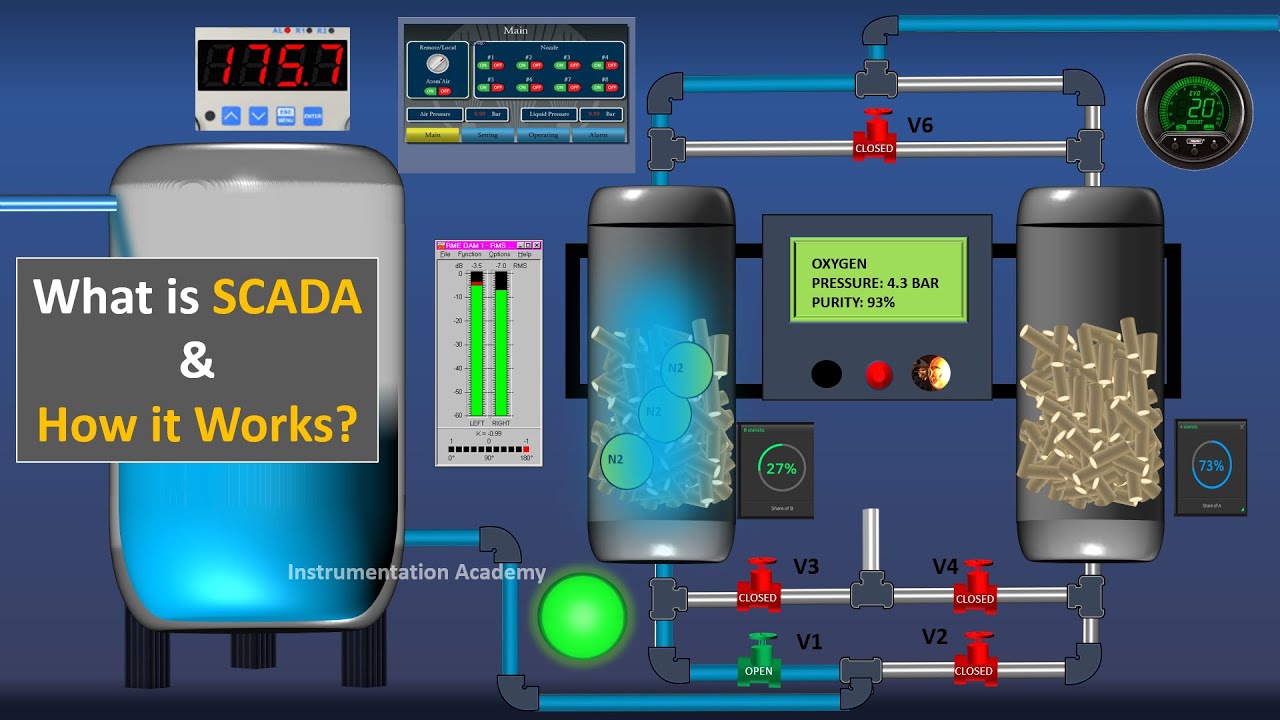

TLDRThis video simplifies the concept of SCADA (Supervisory Control and Data Acquisition) systems, essential for monitoring and controlling industrial processes. It distinguishes between factory-centered and remote SCADA architectures, highlighting key components like PLCs, HMIs, and OPC servers. The video explains the communication protocols that ensure seamless data exchange and outlines the numerous advantages of SCADA, including real-time monitoring, remote access, historical data analysis, and predictive maintenance. Ultimately, SCADA systems empower industries, enhancing operational efficiency, safety, and cost-effectiveness, especially in sectors like oil and gas and utilities.

Takeaways

- 😀 SCADA stands for Supervisory Control and Data Acquisition, a system used to monitor and control industrial processes.

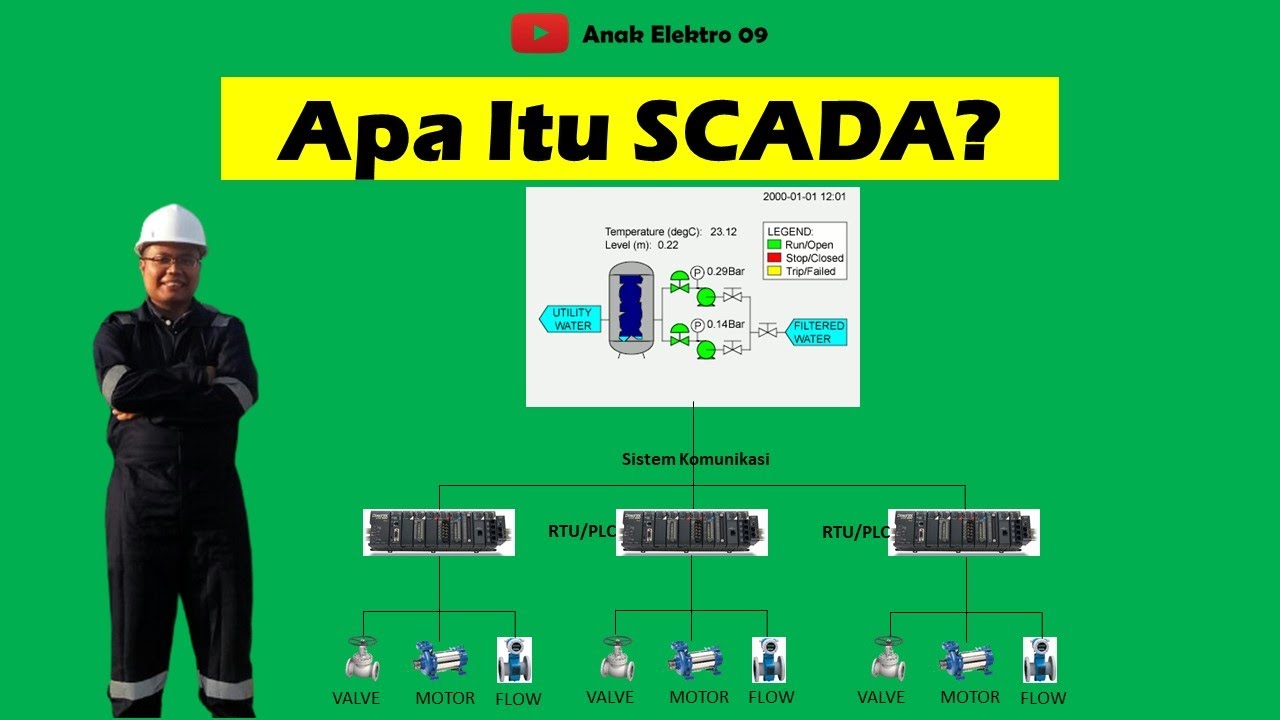

- 🏭 There are two primary architectures for SCADA: Factory-Centered and Remote SCADA.

- 🔧 Factory-Centered SCADA involves instruments like PLCs (Programmable Logic Controllers) that gather and analyze data to send commands to final control elements.

- 🚗 PLCs are analogous to an autopilot in a car, continuously adjusting based on sensor data to ensure smooth operations.

- 🖥️ The HMI (Human-Machine Interface) allows operators to visualize process data in real time, enhancing interaction with the system.

- 📊 The Historian component stores historical data, aiding in trend analysis and performance evaluation for process optimization.

- 🌐 Communication protocols like Modbus, DNP3, and OPC facilitate efficient data exchange between various SCADA components.

- 🛠️ Remote SCADA systems utilize RTUs (Remote Terminal Units) to monitor distant locations, crucial for areas with limited human supervision.

- 🔔 SCADA systems provide real-time monitoring, alarms, and notifications, allowing quick responses to critical situations.

- 💡 Predictive maintenance features in SCADA can predict equipment failures, reducing downtime and optimizing maintenance schedules.

Q & A

What does SCADA stand for?

-SCADA stands for Supervisory Control and Data Acquisition.

What are the main functions of a SCADA system?

-SCADA systems help monitor and control industrial processes, such as oil and gas, power generation, and more.

What are the two types of SCADA architectures mentioned?

-The two types of SCADA architectures are factory-centered SCADA and remote SCADA.

What role do PLCs play in a SCADA system?

-PLCs, or Programmable Logic Controllers, act as the central processing unit, analyzing data from field instruments and sending control commands to actuators and final control elements.

How is data collected in a factory-centered SCADA system?

-In a factory-centered SCADA system, data is collected from instruments like control valves, transmitters, and motors, which are akin to sensors in the human body.

What is the purpose of an HMI in SCADA?

-An HMI, or Human-Machine Interface, serves as the interface between humans and machines, allowing operators to visualize the status and values of various processes in real time.

What distinguishes intelligent RTUs from non-intelligent RTUs in a remote SCADA system?

-Intelligent RTUs analyze data and make decisions based on it, while non-intelligent RTUs merely collect and transmit data without analysis.

What communication methods are used to transmit data from remote sites to the central SCADA system?

-Data from remote sites can be transmitted using various methods such as satellite, radio waves, or cellular networks.

What are some common communication protocols used in SCADA systems?

-Common SCADA communication protocols include Modbus, DNP3, IEC 60870, and OPC.

What are the benefits of implementing a SCADA system?

-SCADA systems provide real-time monitoring, remote access, historical data collection, alarm generation, operational optimization, and enhanced security, leading to improved efficiency and cost savings.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

What is SCADA? Supervisory Control and Data Acquisition

What is SCADA, How SCADA Works, Components, Architecture & Applications. SCADA Tutorial

Pengenalan SCADA (Supervisory Control And Data Acquisition)

When to use PLC ,DCS & SCADA | PLC vs DCS vs SCADA Selection Guide

What is SCADA?

DISTRIBUTE CONTROL SYSTEM (DCS) SISTEM KONTROL TERDISTRIBUSI - DALAM OTOMASI INDUSTRI

5.0 / 5 (0 votes)