Pitch sobre Curva de Escoamento

Summary

TLDRThis video explores the concept of strain hardening, or 'encruamento', in metallurgy, where metals become stronger and more resistant as they undergo plastic deformation. The process is described through the stress-strain curve, with insights into how different metals, like aluminum and stainless steel, behave under mechanical stress. The script explains the relationship between true stress and true strain and emphasizes the importance of understanding these curves for industrial applications, such as metal forming processes. It highlights the role of strain hardening coefficients, material selection, and the influence of heat treatment on a material's deformability and resistance to failure.

Takeaways

- 😀 Metals can behave differently when deformed, either becoming harder or more resistant, a phenomenon known as strain hardening.

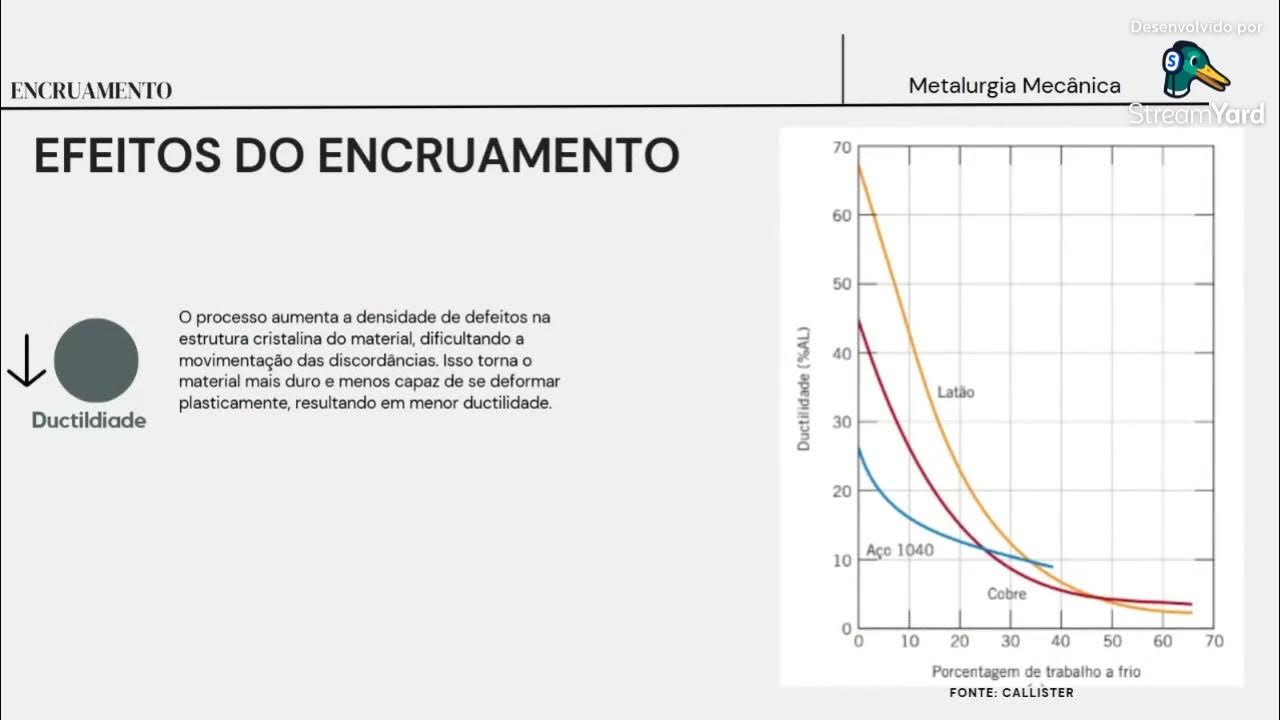

- 😀 Strain hardening is the increase in mechanical strength of metals as they undergo plastic deformation, due to the accumulation and interaction of dislocations in the crystal structure.

- 😀 The flow curve describes the relationship between true stress and true strain, and can be understood using Ludwig’s equation, which includes the material's resistance coefficient and strain hardening exponent.

- 😀 True stress and strain values, which are corrected for changes in cross-sectional area and length, are used to analyze the material's response beyond its elastic limit.

- 😀 The flow curve is valid until necking (strain localization) begins; after this point, the equation becomes less accurate due to concentrated deformation.

- 😀 A comparison between aluminum 2024 and stainless steel 302 shows that aluminum deforms more easily due to a lower strain hardening coefficient, whereas stainless steel strengthens more as it deforms.

- 😀 The strain hardening coefficient plays a crucial role in determining how easily a metal can be formed in manufacturing processes.

- 😀 Materials with a high strain hardening coefficient, like stainless steel, are ideal for applications that require high mechanical resistance, such as deep drawing and structural components.

- 😀 Materials with a low strain hardening coefficient, like aluminum, are more easily shaped and are better suited for processes such as extrusion and drawing.

- 😀 Heat treatments, such as annealing, can reduce the strain hardening coefficient and make materials more ductile, whereas cold working increases the coefficient for greater mechanical strength.

- 😀 Understanding the flow curve and strain hardening behavior is essential for optimizing manufacturing processes, ensuring material suitability, and preventing premature failure in industrial applications.

Q & A

What is strain hardening, and why is it important in metallurgy?

-Strain hardening is a phenomenon where a metal becomes harder and more resistant to deformation as it undergoes plastic deformation. It occurs due to the accumulation and interaction of dislocations in the material's crystal structure. Understanding this behavior is essential for predicting how metals respond to mechanical stresses and optimizing their use in manufacturing processes.

How is the flow curve related to strain hardening?

-The flow curve describes the relationship between true stress and true strain during plastic deformation. It is directly related to strain hardening, as it reflects how the material's resistance increases with deformation. The curve helps quantify the material's behavior under stress, including its ability to resist further deformation.

What is the role of Ludwig's equation in analyzing strain hardening?

-Ludwig's equation relates true stress to true strain and allows for the determination of material properties such as the strain hardening coefficient (n) and the resistance coefficient (K). This equation helps in analyzing how different materials react to deformation and how they strengthen during the process.

How does the true stress-strain curve differ from the engineering stress-strain curve?

-The true stress-strain curve corrects for changes in the material's cross-sectional area and length during deformation, providing a more accurate representation of how the material behaves under stress. In contrast, the engineering stress-strain curve uses the original area and length values, which can lead to inaccuracies, especially in the plastic deformation region.

What is the significance of the point of necking in a true stress-strain curve?

-The point of necking marks the onset of localized deformation in the material, where the cross-sectional area starts to decrease rapidly. After this point, the true stress-strain curve becomes less reliable, as the material undergoes highly concentrated strain that is no longer uniformly distributed.

How do materials like aluminum 2024 and stainless steel 302 differ in terms of strain hardening?

-Aluminum 2024 has a lower strain hardening coefficient, meaning it deforms more easily and is less resistant to further deformation, which makes it suitable for processes like deep drawing. On the other hand, stainless steel 302 has a higher strain hardening coefficient, meaning it becomes significantly stronger as it deforms, making it ideal for applications requiring high mechanical strength.

Why is the strain hardening coefficient important for material workability?

-The strain hardening coefficient determines how a material responds to plastic deformation. Materials with high strain hardening coefficients, like stainless steel, can endure large deformations before failure, making them suitable for processes that involve extensive shaping. Materials with low coefficients, like aluminum, are easier to mold and form without excessive hardening during deformation.

What role do thermal treatments like annealing play in strain hardening?

-Thermal treatments like annealing reduce the strain hardening coefficient by softening the material. This makes the metal more malleable, facilitating processes such as forming and shaping. Conversely, cold working processes increase the strain hardening coefficient, enhancing the material's strength.

How can strain hardening affect the design and selection of materials for engineering applications?

-Strain hardening affects the design and selection of materials by determining how they will perform under mechanical stress. Materials with high strain hardening coefficients are preferred in applications requiring high strength and energy absorption, such as impact-resistant structures, while those with low coefficients are ideal for processes that involve shaping, like extrusion or drawing.

What are the industrial applications of understanding the flow curve and strain hardening?

-Understanding the flow curve and strain hardening is crucial for optimizing metalworking processes like rolling, stamping, and forging. It helps engineers predict how materials will behave under different stress conditions, preventing premature failure, improving product quality, and enhancing material efficiency in manufacturing processes.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Pitch sobre Encruamento

Understanding plasticity theory (for Mises UMAT)

Materiais e Processos de Fabricação para Engenharia de Produção - Processos de Laminação

Geologic Stress and Strain: Can solid rock bend?

Aluminium and the Age of Flight - Metal: How It Works - BBC Four

Experiments with the Bubble Model of Metal Structure 1952 - Sir Lawrence Bragg, W.M Lomer, J.F. Nye

5.0 / 5 (0 votes)