Pneumatic Cylinder Working explained (Animation)

Summary

TLDRThis video explains the workings of a pneumatic cylinder, a linear actuator powered by compressed air. It highlights the key components, such as the piston rod, seals, cushioning pistons, and the cylinder itself. The video covers how the pneumatic valve directs air to different sections of the cylinder, enabling the extension and retraction of the piston. The theoretical force exerted is calculated based on air pressure and the effective piston area. Additionally, factors like friction and rod diameter impact the cylinder’s force capacity. The system's design ensures gradual stopping, noise reduction, and efficient performance.

Takeaways

- 😀 Pneumatic cylinders are linear actuators powered by compressed air, providing force to move loads.

- 😀 The most common type of pneumatic actuator is the double-acting cylinder, which uses a piston rod to transfer force.

- 😀 Cushioning pistons prevent hard shocks at the end of the stroke by gradually stopping the piston.

- 😀 A static seal ensures airtight sealing between the piston and rod in the cylinder.

- 😀 Piston guide rings prevent metal-to-metal contact between the piston and cylinder for smooth operation.

- 😀 Piston seals ensure airtight sealing between the cylinder and piston for efficient functioning.

- 😀 Pneumatic cylinders are typically housed in aluminum or steel cylindrical bores with cylinder caps and heads at both ends.

- 😀 Adjustable cushioning screws are installed on each end of the cylinder to optimize stopping at the end of the stroke.

- 😀 The assembly is held together with tie rods, which also provide compressive and tensile strength to the actuator.

- 😀 The pneumatic valve controls the flow of compressed air in and out of the cylinder, with ports directing airflow and exhaust.

- 😀 The valve directs compressed air to the appropriate end of the cylinder for the extension and retraction of the piston, with exhaust gases being muffled to reduce noise.

Q & A

What is a pneumatic cylinder?

-A pneumatic cylinder is a linear actuator powered by compressed air that supplies force to a load. It is commonly used in industries for tasks requiring linear motion.

What is the function of the piston rod in a pneumatic cylinder?

-The piston rod transfers the force generated by compressed air to the load. It is a critical component for moving the load based on air pressure.

Why are cushioning pistons used in pneumatic cylinders?

-Cushioning pistons prevent hard shocks at the end of the stroke by gradually slowing down the piston’s movement, ensuring smoother operation and protecting the system from damage.

What is the role of the static seal in a pneumatic cylinder?

-The static seal ensures airtight sealing between the piston and the rod, preventing air leakage and maintaining the cylinder’s pressure integrity.

How do piston guide rings contribute to the functionality of a pneumatic cylinder?

-Piston guide rings are designed to prevent metal-to-metal contact between the piston and the cylinder, reducing wear and ensuring smooth operation.

What materials are commonly used to make pneumatic cylinders?

-Pneumatic cylinders are typically made of aluminum or steel, materials that are lightweight and strong enough to withstand the internal pressures.

What is the purpose of adjustable cushioning screws in pneumatic cylinders?

-Adjustable cushioning screws allow users to fine-tune the cushioning effect at both ends of the stroke, optimizing the deceleration of the piston at the end of its travel.

How does the pneumatic valve control the movement of the piston?

-The pneumatic valve directs the flow of compressed air to either side of the piston, enabling the extension or retraction of the piston based on the pressure difference.

What happens during the extension stroke of a pneumatic cylinder?

-During the extension stroke, compressed air is directed to the cap end of the cylinder, pushing the piston towards the head end. The exhaust gas from the opposite side of the piston escapes through the exhaust port and muffler.

How is the theoretical force of a pneumatic cylinder calculated?

-The theoretical force is calculated by multiplying the relative pressure (the difference between the supplied air pressure and atmospheric pressure) by the effective area of the piston on which the pressure is exerted.

What factors influence the capacity of a pneumatic actuator?

-The capacity of a pneumatic actuator is influenced by the rod diameter, stroke length, frictional losses, and the effective area of the piston. These factors all play a role in determining the actuator's performance.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Pneumatic Cylinder: How Does It Work?

Basics of Pneumatics and Pneumatic Systems: Part 1 (Animation / Sub)

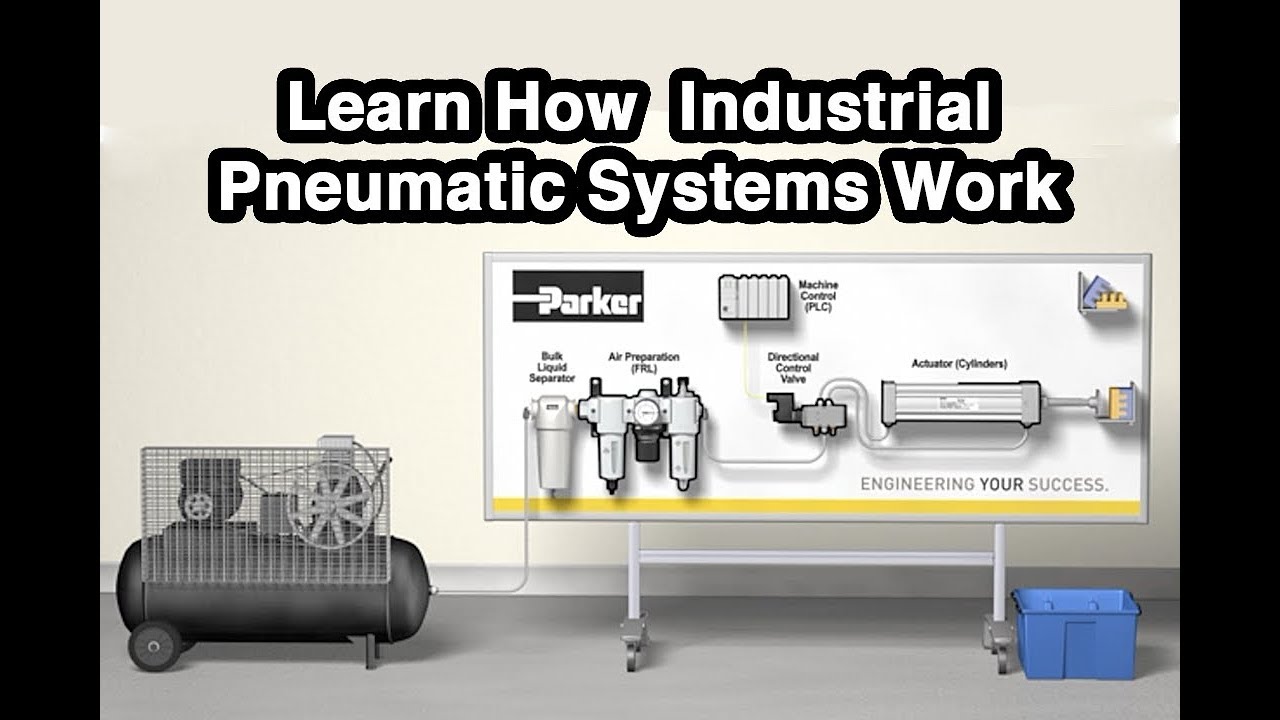

How a Industrial Pneumatic Systems Works And The Five Most Common Elements Used

Poisoning AI with ".аss" subtitles

Directional Control Valve Working Animation | 5/2 Solenoid Valve | Pneumatic Valve Symbols Explained

Actuators - Explained. How do Actuators work - Using Lego to demonstrate the principals

5.0 / 5 (0 votes)