INTERESSANTE Como é feito TELHA

Summary

TLDRThe video outlines the detailed process of ceramic tile production, from the initial analysis and milling of certified clays to their final packaging and shipment. The clay undergoes a series of processes, including humidification, vacuum compaction, and extrusion, followed by drying and firing in a continuous kiln. Various quality checks are performed, such as moisture measurement, resistance tests, and water absorption. The result is a certified, high-quality tile that meets industry standards, ensuring durability and reliability for customers.

Takeaways

- 😀 The company uses certified clay that undergoes a thorough analysis before processing.

- 😀 The clay is processed in a hammer mill to create a grain packing structure.

- 😀 After grinding, the clay undergoes minimal humidification to avoid pore formation, which improves strength.

- 😀 The humidified clay is passed through an extruder, where it is compacted and air is removed using a vacuum chamber.

- 😀 The clay is formed into a rod shape, which is then processed by moderators to produce tiles.

- 😀 The tiles are dried using high-performance motors that run 24/7, initially using vaporization and later drying with dry air.

- 😀 After drying, the tiles have only 1-2% humidity and are placed on wagons for transport to the kiln.

- 😀 The continuous kiln operates at 120°C and further processes the tiles, which are then selected and packaged for shipping.

- 😀 Laboratory tests are conducted on the tiles, including tests for dry strength, bending, and moisture resistance.

- 😀 A destructive test is performed to measure the tile's strength by applying a load until the tile breaks, ensuring its durability.

- 😀 All tests are done daily to ensure the tiles meet safety, quality standards, and compliance with norms.

Q & A

What is the initial step in processing the clay at Cerâmica Mund?

-The initial step involves analyzing and studying the clay to ensure it meets required standards before processing.

How is the clay reduced in size during the process?

-The clay is reduced in size by being placed in a hammer mill, which grinds it into smaller grains, creating a compact grain packing.

What is the purpose of the humidification step in the clay processing?

-Humidification is done to add minimal moisture to the clay, which helps increase its strength by preventing the formation of pores during evaporation.

What function does the extruder serve in the clay processing?

-The extruder compact the clay and works with a vacuum chamber to remove air, ensuring that the clay forms a compact block.

What happens to the clay after it is extruded and compacted?

-The extruded clay is formed into a rod, which then goes through rollers to shape it into tiles.

How are the tiles dried after they are formed?

-The tiles are dried in a continuous drying system that operates 24/7, first using vaporization and then applying dry air to ensure only 1-2% moisture remains.

What role do the wagons play in the tile production process?

-The wagons are used to transport the tiles into the continuous kiln for the firing process.

What temperature does the continuous kiln reach during the firing process?

-The continuous kiln operates at a temperature of 120°C during the firing process.

What types of tests are conducted on the tiles before they are shipped?

-Before shipping, the tiles undergo various tests including resistance to drying, firing, and wet conditions, as well as tests for water absorption and warping.

How is the resistance test performed on the tiles?

-The resistance test is a destructive test where a tile is placed on support, and a load is applied until the tile breaks, helping to measure its durability.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

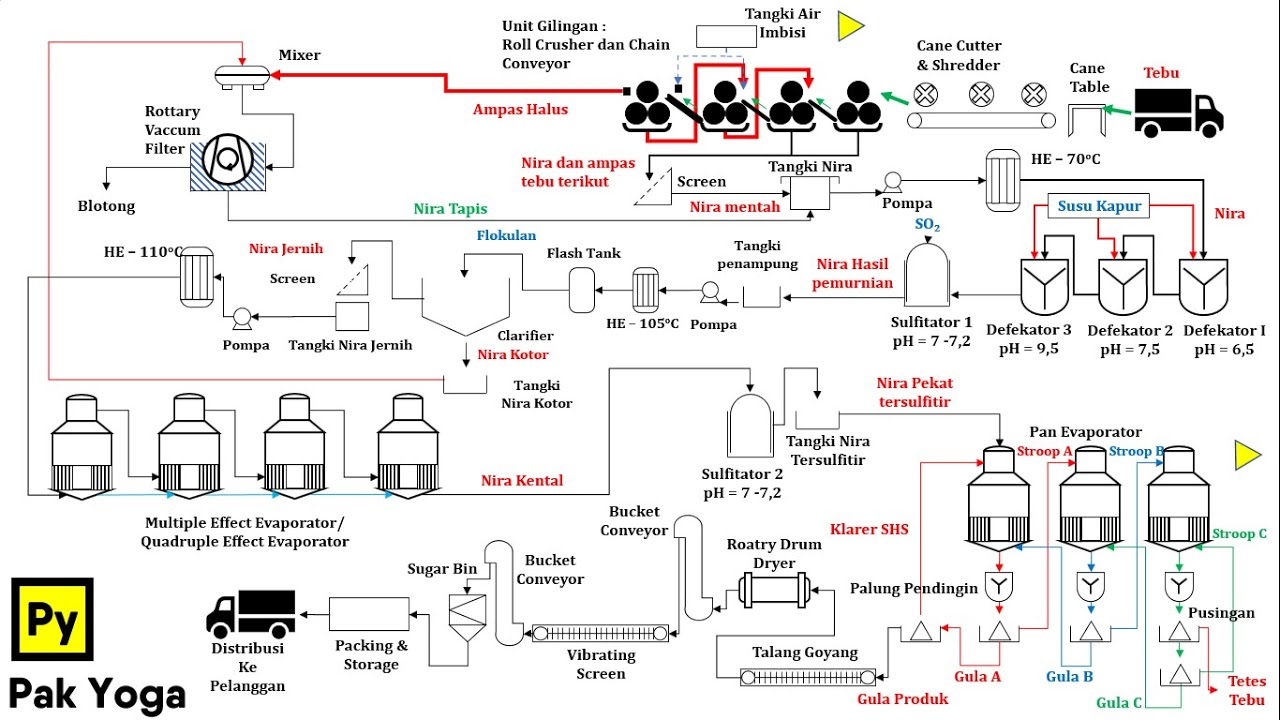

Kimia Industri - Diagram Alir Proses Pembuatan Gula tebu

Amazing Modern Ceramic Tile Manufacturing Process With Advance Technology And Creative Workers

Proses Produksi Pembuatan Keramik di Pabrik Modern | Bagaimana Cara Pembuatan Keramik

Process de fabrication du ciment - Ciments Calcia

Flow Process of SIR 20 at Unit Pematang Kiwah

How Its Made: Ceramic Tiles

5.0 / 5 (0 votes)