Deformation Processes 1 Fundamental

Summary

TLDRThis video script delves into the key concepts of metal forming, covering the various stresses involved (compressive, tensile, shear) and the impact of factors like temperature and strain rate on the material. It classifies metal forming processes into bulk deformation (e.g., rolling, forging) and sheet metal working (e.g., bending, cutting). The script highlights the importance of temperature, categorizing processes as cold, warm, or hot working, with a special focus on isothermal forming. It also discusses strain rate sensitivity and its effects on resistance to deformation, emphasizing how these factors interact to optimize the metal forming process.

Takeaways

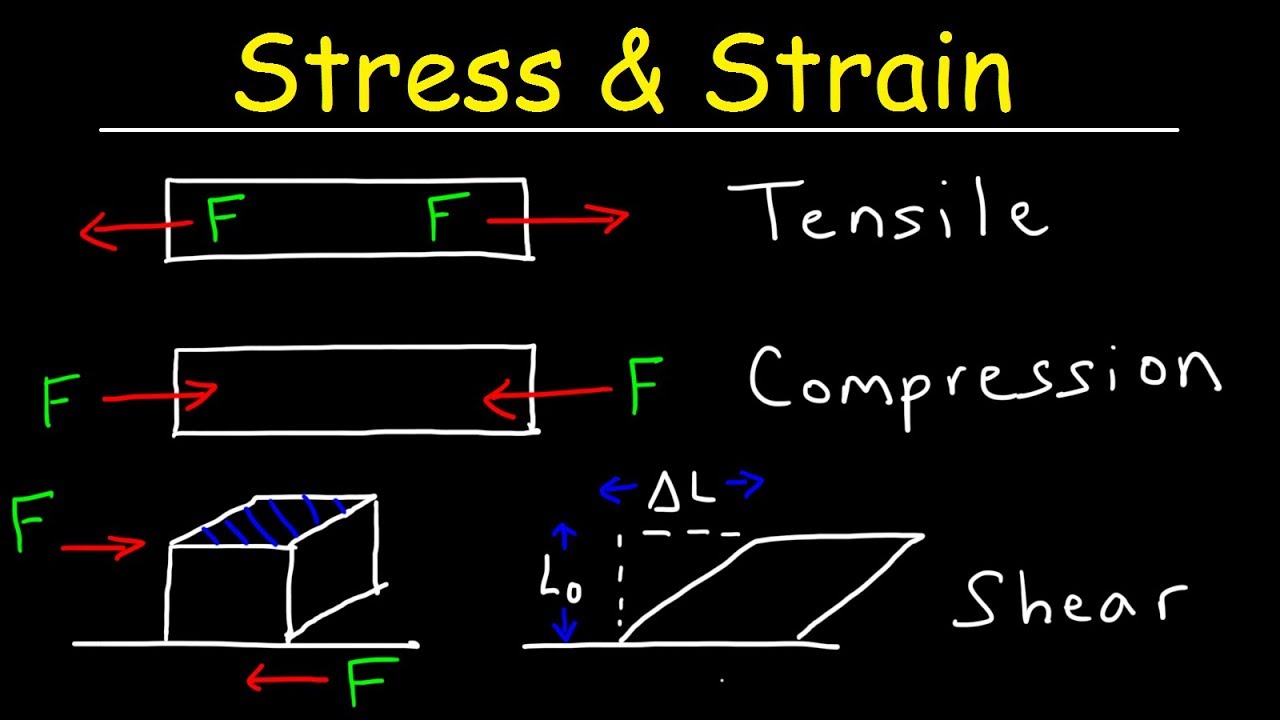

- 😀 Metal forming involves various stress types: compressive, tensile, shear, and size stresses.

- 😀 Metals with lower yield strength and higher ductility are easier to form.

- 😀 Metal ductility increases and strength decreases with rising temperatures.

- 😀 Bulk deformation processes include rolling, forging, extrusion, and wire drawing, with low surface area to volume ratios.

- 😀 Sheet metal working involves high surface area to volume ratio geometries like sheets, strips, and coils, including bending and cutting.

- 😀 In the elastic region, material behavior follows Hooke's law; in the plastic region, it follows a flow curve based on true stress and strain.

- 😀 Strain hardening increases strength in most metals at room temperature during deformation.

- 😀 Flow stress is essential for deformation at a constant strain rate in the plastic region.

- 😀 At higher temperatures, lower force and power are required for metal deformation due to decreased strength and increased ductility.

- 😀 Metal forming processes are classified into cold, warm, and hot working, with each having distinct temperature ranges and advantages, such as reduced power requirements in warm working.

Q & A

What are the main stresses involved in metal forming?

-The main stresses involved in metal forming are compressive stresses, tensile stresses, shear stresses, and size stresses.

How does temperature affect the ductility and strength of metals?

-As temperature increases, the ductility of the metal increases, while its strength decreases. This is because higher temperatures allow the metal to deform more easily, but reduce its resistance to deformation.

What is the difference between bulk deformation and sheet metal working processes?

-Bulk deformation processes involve shaping metals with low surface-area-to-volume ratios (e.g., billets, bars), resulting in significant changes in shape. Sheet metal working, on the other hand, involves deforming materials with high surface-area-to-volume ratios, like sheets and strips, with processes like bending and cutting.

What are the key examples of bulk deformation processes?

-Key examples of bulk deformation processes include rolling, forging, extrusion, and wire drawing.

What is the role of strain rate in metal forming?

-Strain rate refers to the change in strain over time. A higher strain rate increases the resistance to deformation, which leads to higher flow stress. At higher strain rates, the metal becomes harder to deform.

How does cold working differ from hot working?

-Cold working is performed at or near room temperature, enhancing strength through strain hardening but requiring more force and possibly leading to fractures. Hot working occurs at high temperatures (above the recrystallization point), reducing resistance to deformation, and typically results in products with isotropic strength properties.

What are the advantages of warm working over cold and hot working?

-Warm working requires less force than cold working and can handle more intricate geometries. It also reduces the need for annealing and offers improved material properties without reaching the high temperatures of hot working.

What is strain rate sensitivity, and how does it affect metal forming?

-Strain rate sensitivity refers to the change in material behavior with respect to the strain rate. As strain rate increases, the resistance to deformation increases, leading to higher flow stress. At higher temperatures, the effect of strain rate sensitivity becomes more pronounced.

What is isothermal forming, and how does it help in metal forming processes?

-Isothermal forming is a process where the workpiece and the forming tools are heated to the same temperature to eliminate thermal gradients. This reduces surface cooling problems and minimizes tool wear while improving process control.

How does the temperature affect the flow stress of metals during deformation?

-At higher temperatures, the flow stress of metals decreases, making it easier to deform the material. This is because the material becomes softer as it is heated, reducing the force required for deformation.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Tensile Stress & Strain, Compressive Stress & Shear Stress - Basic Introduction

Airframes & Aircraft Systems #1 - Aircraft Structures - Loads Applied to the Airframe

Proses Manufaktur - Pengantar Proses Pembentukan Logam - Intro to Metal Forming #BangDosen

Ductile to Brittle Transition

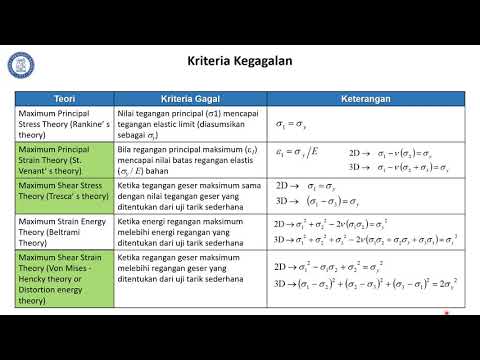

Analisis Kegagalan Logam: Modul 1 Segmen 2 (Kriteria Kegagalan)

Materials Science Mechanical Engineering - Part 1 Stress and Strain Explained

5.0 / 5 (0 votes)