Analisis Kegagalan Logam: Modul 1 Segmen 2 (Kriteria Kegagalan)

Summary

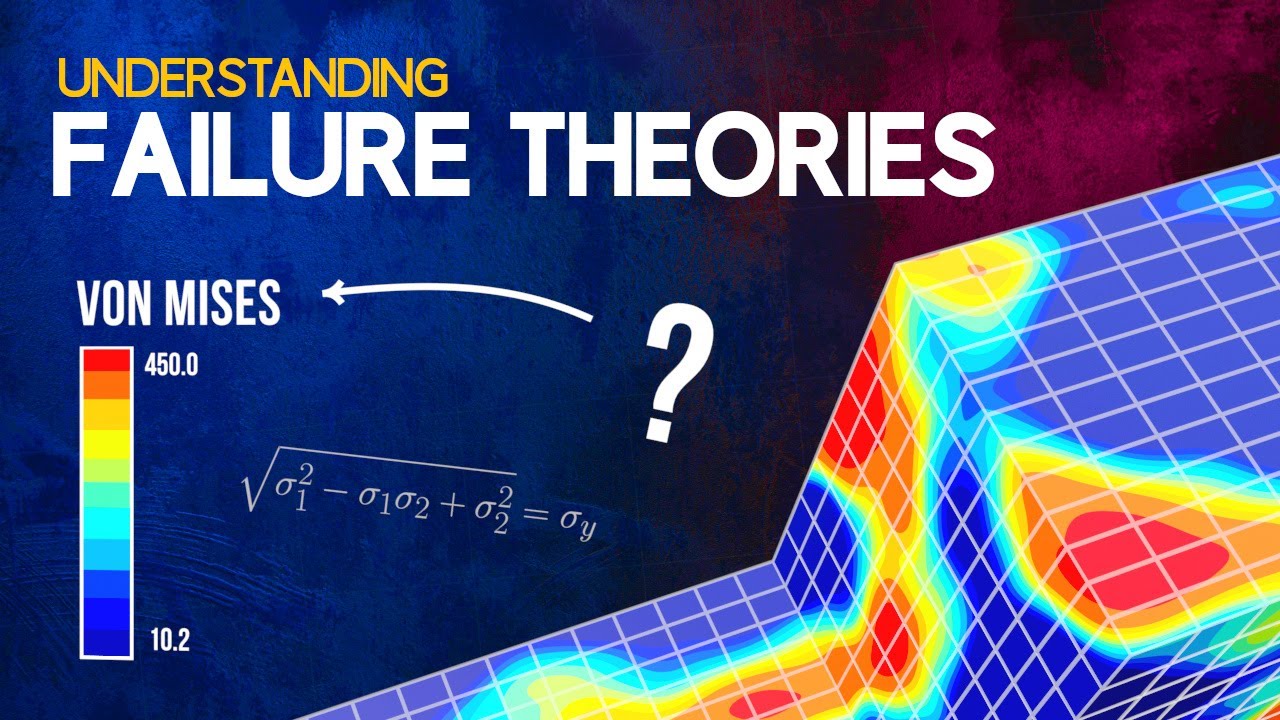

TLDRIn this lecture, Ahmad from the Metallurgical Engineering program delves into metal failure analysis, discussing the criteria for failure in both ductile and brittle materials. He explores various failure theories, including those based on stress, strain, shear, and energy, explaining how these theories are applied using equations and uniaxial tensile tests. A case study demonstrates how to evaluate the failure of a steel component subjected to different stress types using the Von Mises criterion. The lecture concludes by previewing the next topic on failure categories, offering a comprehensive overview of material failure analysis.

Takeaways

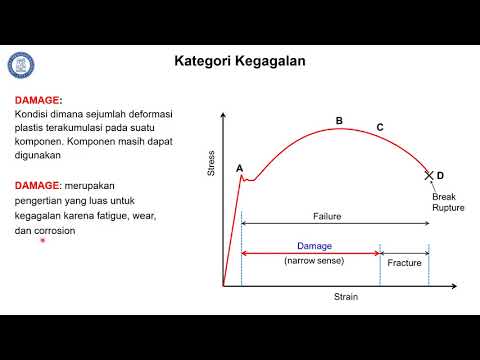

- 😀 Ductile materials fail through plastic deformation, while brittle materials fail via fracture.

- 😀 Failure in materials is influenced by temperature, loading conditions, and defects present in the material.

- 😀 Theories for material failure include Tresca, Von Mises, and other stress/strain-based theories.

- 😀 Shear stress is an important factor in determining material failure, especially in Von Mises theory.

- 😀 Failure criteria are applied by comparing material stress conditions against the material's yield strength.

- 😀 In ductile materials, failure begins with yielding and plastic deformation before fracture occurs.

- 😀 Brittle materials fail when a critical fracture stress is exceeded, often without prior plastic deformation.

- 😀 Stress tests such as uniaxial tensile tests are used to validate failure theories and determine material limits.

- 😀 When calculating failure, it is important to consider both normal stress and shear stress in the material.

- 😀 In the example given, a steel component with tensile strength of 510 MPa was analyzed and found not to fail under specific loading conditions.

Q & A

What is the general classification of materials based on their failure behavior?

-Materials are generally classified into two types based on their failure behavior: ductile and brittle materials.

What initiates failure in ductile materials?

-In ductile materials, failure begins with yielding or plastic deformation when the applied stress exceeds the material's yield strength.

How does failure occur in brittle materials?

-Failure in brittle materials is determined by the occurrence of fracture, where the material breaks without undergoing significant plastic deformation.

What factors influence the failure characteristics of a material?

-The failure characteristics of a material are influenced by temperature, stress state, loading rate, and the presence of defects.

Can a ductile material fail in a brittle manner under certain conditions?

-Yes, a ductile material can fail in a brittle manner under certain conditions, such as low temperatures or high strain rates.

What are the common failure theories for ductile materials?

-The common failure theories for ductile materials include the Von Mises, Tresca, and Saint-Venant criteria.

What is the purpose of using failure criteria like Von Mises or Tresca?

-Failure criteria like Von Mises or Tresca are used to predict material failure by comparing the stress states to theoretical limits, ensuring safe design.

What is the significance of using uniaxial tensile tests in failure analysis?

-Uniaxial tensile tests are significant because they provide essential data for determining the material’s stress-strain behavior and applying failure criteria.

How is the failure of a material evaluated using the Von Mises theory?

-The failure of a material is evaluated using the Von Mises theory by calculating the equivalent stress, which is compared to the material's yield strength.

In the provided example, did the steel component fail based on the applied stresses?

-No, the steel component did not fail. The calculated equivalent stress (225 MPa) was below the steel’s yield strength (510 MPa), indicating no failure.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)