3D Printing - Introduction to Slicing

Summary

TLDRThis video provides an essential guide to 3D printing slicing software, explaining how it converts 3D models into printable layers through G-code. Key topics include setting up your printer, selecting options like rafts, brims, or skirts for better adhesion, and adjusting print shells, infill, resolution, and speed for optimal results. It also covers the use of supports for overhangs and how cooling fans and layer height affect print quality. Whether you're a beginner or experienced, this video helps you understand how various slicing settings influence the final print.

Takeaways

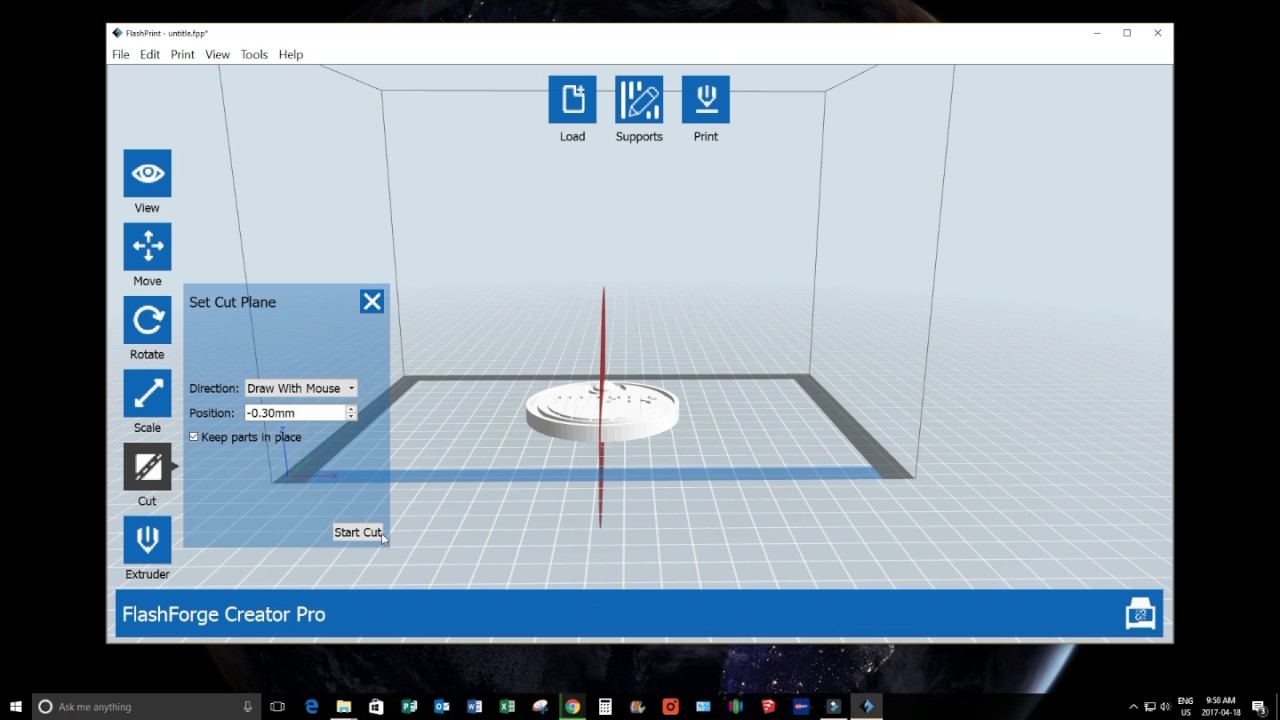

- 😀 Slicing programs convert STL files into paths that 3D printers can understand, generating G-code to guide the printing process.

- 😀 When setting up slicing software, you may need to manually add printer parameters if your specific model isn't listed.

- 😀 A raft can help with adhesion if your printer bed is uneven or for tall, thin models, ensuring easy removal if set correctly.

- 😀 A brim is another option for improved bed adhesion, while a skirt is used to purge the nozzle before the print begins.

- 😀 The 'shell' of a print is determined by the number of outer perimeters, and a thicker shell results in a stronger but longer print.

- 😀 Infill refers to the internal structure of a print, with 100% infill being solid and 0% being hollow; denser infill increases strength but lengthens the print time.

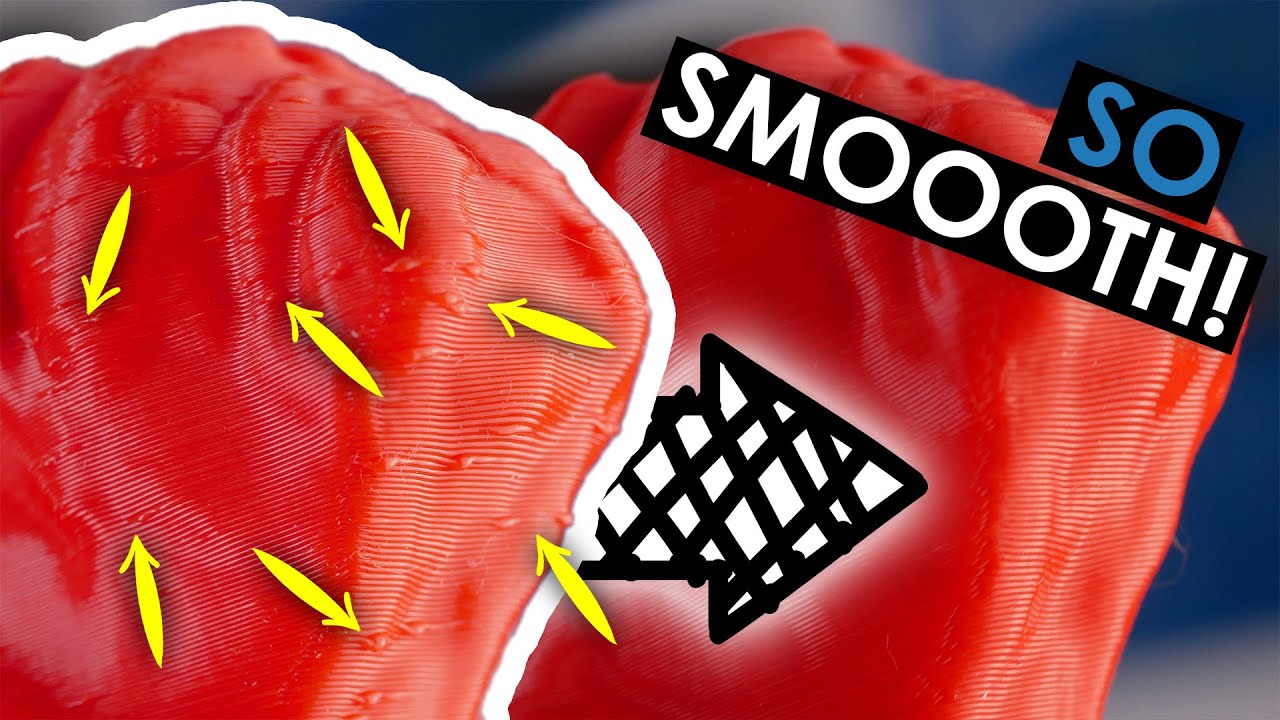

- 😀 Higher print resolution (smaller layer height) produces smoother parts but may reduce print speed and strength, with the maximum layer height being 80% of your nozzle diameter.

- 😀 Increasing the print speed reduces accuracy and surface finish, but might be acceptable depending on the specific project.

- 😀 Supports are necessary for overhangs greater than 45° (ABS) or 45-65° (PLA) to avoid printing issues.

- 😀 The use of cooling fans and smaller layer heights improves overhang performance and surface quality.

- 😀 Testing maximum overhang capabilities can be done by printing specific overhang test models available online.

Q & A

What is the primary function of slicing software in 3D printing?

-Slicing software takes your 3D model, typically in STL format, and slices it into thin layers. It then converts these layers into paths, saving them as G-code that the 3D printer can interpret to create the object layer by layer.

What is the purpose of a raft in 3D printing?

-A raft is used to improve bed adhesion, especially when the printer bed is uneven or when printing tall, thin objects that may need extra support. A properly configured raft will snap off cleanly after the print.

What is the difference between a 'brim' and a 'skirt' in 3D printing?

-A brim is an additional layer of material printed around the base of your object to improve bed adhesion, while a skirt is used to purge the printer nozzle before printing the actual part, ensuring smoother printing.

How does the number of shell perimeters affect the print strength and time?

-Increasing the number of outer perimeters (shells) increases the thickness of the print walls, making the part stronger. However, this also increases the print time significantly.

What does the term 'infill' refer to in 3D printing?

-Infill refers to the interior structure of your print, which can be adjusted in terms of density and pattern. A higher infill percentage results in a stronger but longer print, while 0% infill produces a hollow object.

What is the impact of layer height on print quality and speed?

-A smaller layer height increases print resolution and results in smoother, more accurate parts. However, it also increases print time. A larger layer height speeds up the print but reduces accuracy and surface finish.

Why should you never exceed 80% of the nozzle diameter when setting the maximum layer height?

-Exceeding 80% of the nozzle diameter for layer height can lead to poor layer adhesion and a less stable print, negatively affecting print quality and strength.

How does print speed affect the final print outcome?

-Increasing the print speed reduces the accuracy and surface finish of the print. However, in some cases, it might not be an issue depending on the part's function and appearance.

When should you use supports in 3D printing?

-Supports should be used when a portion of your model has an overhang greater than 45 degrees for ABS or 45 to 65 degrees for PLA. Supports help to prevent the print from sagging or failing during the printing process.

How can cooling fans improve the printing of overhangs?

-Using cooling fans can help improve the printing of overhangs by cooling the layers faster, making the printed material solidify more quickly and reduce the risk of sagging or failure. This is especially useful for prints with larger overhangs.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)