Transmitter Explained | Types of Transmitters

Summary

TLDRThis video introduces the concept of transmitters in process control, explaining their role in converting sensor signals into standard output signals for process measurement and control. It discusses the difference between transmitters in telecommunications and process control, outlining signal types such as pneumatic, voltage, and current. The video covers the integration of transmitters in control loops, highlighting major variables like pressure, temperature, level, and flow. It also explores the differences between 2-wire and 4-wire configurations, the advent of 'Smart' Transmitters, and the importance of protocols like HART in modern automation systems.

Takeaways

- 😀 A Transmitter in process control converts the signal from a sensor into a standard instrumentation signal representing a process variable.

- 😀 The telecommunications world uses transmitters to produce radio waves, but in process control, they are used for measuring and controlling variables.

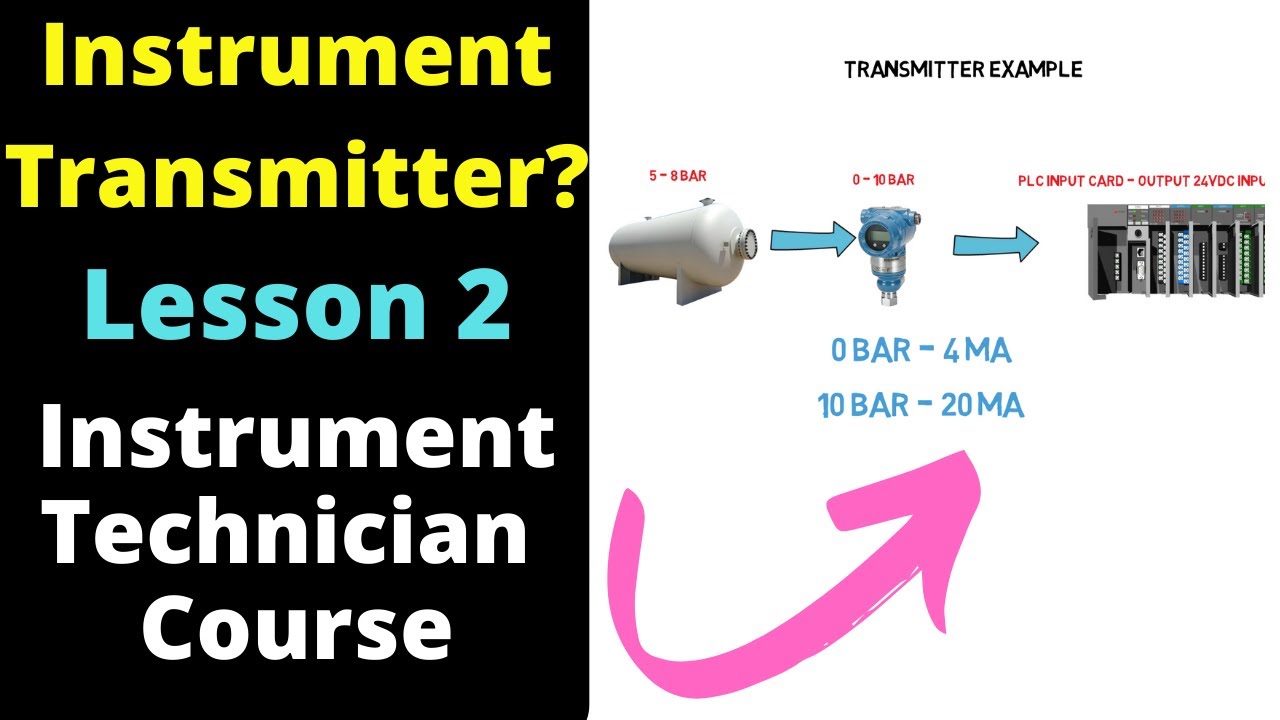

- 😀 The standard pneumatic signal for transmitters is 3 to 15 psi, while electrical signals are typically 1 to 5 volts or 4 to 20 mA.

- 😀 A Transducer and a Transmitter are often considered the same device in industrial instrumentation, though this can vary.

- 😀 Transmitter output signals represent 0 to 100% of a physical variable being measured, like temperature or pressure.

- 😀 Process control loops consist of a transmitter, controller, and final actuator, with the transmitter converting sensor signals into process variable outputs.

- 😀 Major process variables measured by transmitters include Pressure, Level, Temperature, and Flow, though other variables like Position and Speed are also measured.

- 😀 Transmitters require a power supply to operate, with 2-wire and 4-wire configurations being common. 4-wire systems include both power and signal lines, while 2-wire systems share the same wires for power and signal.

- 😀 Smart Transmitters offer additional features like transmitting and receiving digital information, such as instrument tag names, calibration data, and sensor diagnostics.

- 😀 Protocols like HART are often used with Smart Transmitters to facilitate communication and diagnostics.

- 😀 Newcomers can access free PLC programming lessons from RealPars through their app, which also offers exclusive, high-quality, weekly courses on industrial automation topics.

Q & A

What is a transmitter in the context of process control?

-In process control, a transmitter is a device that converts the signal produced by a sensor into a standard instrumentation signal, representing a process variable being measured and controlled.

What are the typical types of signals produced by transmitters?

-The standard pneumatic signal is 3 to 15 psi, while the standard electrical signals are 1 to 5 volts or 4 to 20 mA.

How does a transmitter fit into the process control loop?

-A transmitter converts the sensor's signal to a process variable signal. The controller compares the process variable with the setpoint and generates an output signal, which is used to control the final actuator (e.g., a valve).

What are the four major process variables measured by transmitters?

-The four major process variables are Pressure, Level, Temperature, and Flow.

What is the difference between a transmitter and a transducer in the industrial field?

-In the industrial instrumentation field, some people use the terms 'transducer' and 'transmitter' interchangeably, although they are technically distinct. A transducer generally refers to a device that converts one form of energy to another, while a transmitter typically converts sensor signals into standardized process signals.

What are the two types of wiring configurations for transmitters?

-Transmitters can be configured as 4-wire or 2-wire. A 4-wire transmitter has separate power and signal lines, while a 2-wire transmitter shares the same two wires for both power and signal.

What is the main advantage of a 'smart' transmitter?

-A 'smart' transmitter not only transmits the standard 4-20 mA process variable signal but also communicates additional digital information, such as instrument tag names, calibration data, and sensor diagnostics, typically using protocols like HART.

What are some other variables that transmitters can measure beyond pressure, level, temperature, and flow?

-In addition to the major four variables, transmitters can measure other variables such as Position, Speed, and chemical properties like pH and Conductivity.

How do pneumatic and electrical signals differ in process control?

-Pneumatic signals in process control are usually within the range of 3 to 15 psi, while electrical signals are typically either 1 to 5 volts or 4 to 20 mA.

What does the controller do in the process control loop?

-The controller compares the process variable (PV) with the setpoint (SP) and determines the necessary action to adjust the process, generating an output signal that influences the final actuator.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

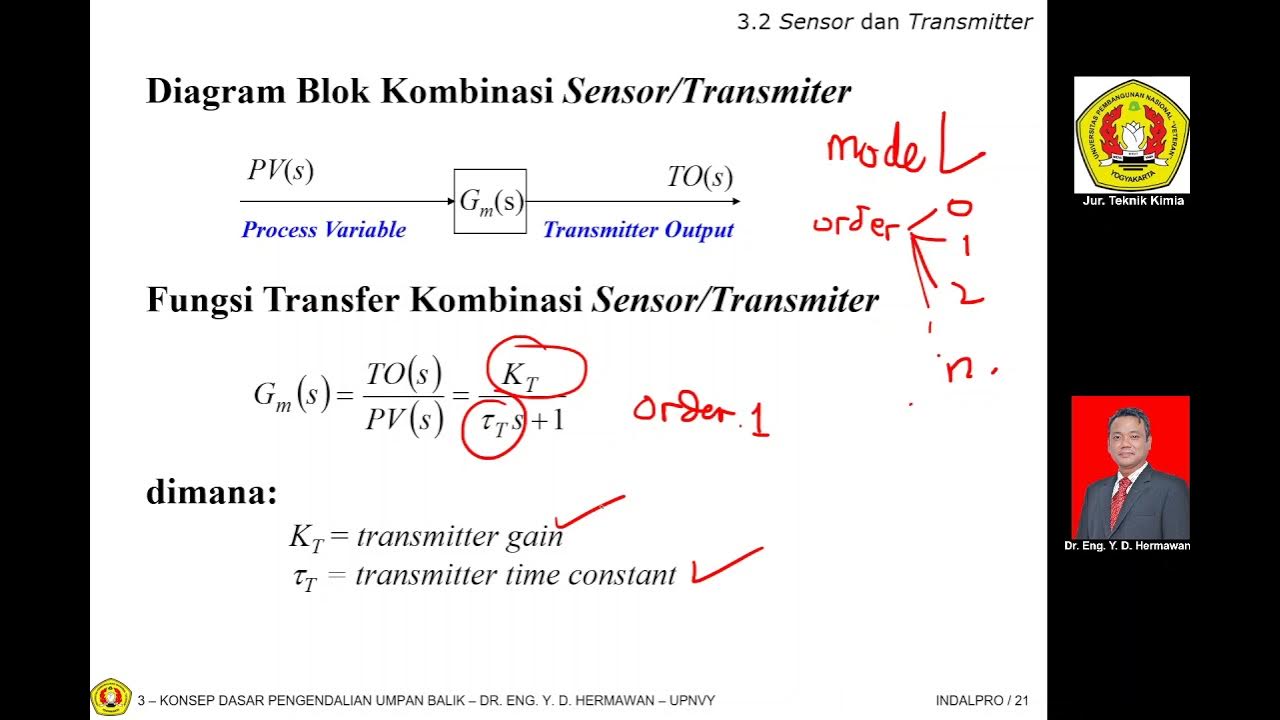

2021 04 05 IPP 3 2 Sensor Transmitter

Introduction to Transducer - Transducers and Sensors - Electronic Instruments and Measurements

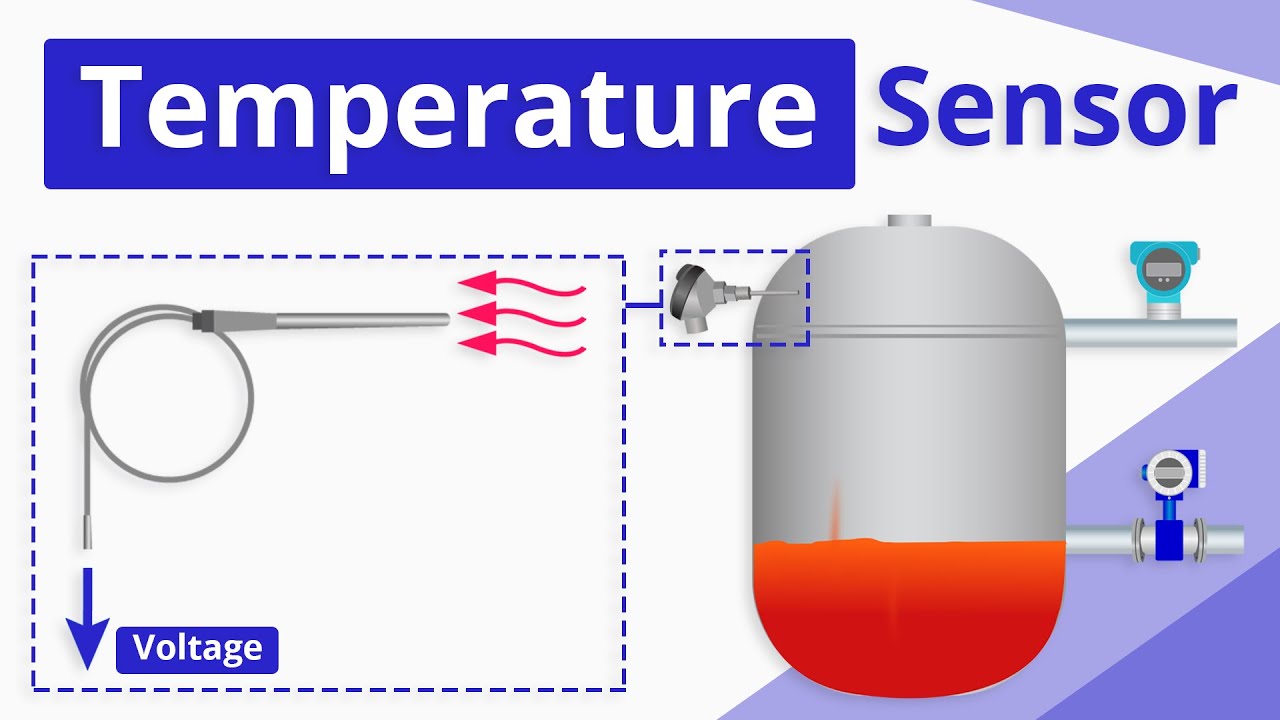

What is a Temperature Sensor?

MACAM-MACAM TRANSDUSER INPUT (SENSOR) UNTUK EMBEDDED SYSTEMS

What is a Transmitter -Instrumentation Technician Course - Lesson 2

Control System Input Signals (Step, Ramp, Parabolic, Noise, Rectangular, Impulse, and Sinusoidal)

5.0 / 5 (0 votes)