Mengenal Sistem Kontrol Proses

Summary

TLDRThis video explains the crucial role of control systems in modern industrial processes. It draws parallels to car driving, where various actions like monitoring speed, steering, and fuel levels are essential for control. In industries, control systems ensure safety, efficiency, and quality by regulating processes using measurement elements, controllers, and actuators. The video highlights both automated and manual control systems, showing how automation offers consistency, while manual control provides flexibility. The importance of control rooms in overseeing operations and maintaining normal functioning is also emphasized, showcasing its relevance in industries like oil refining.

Takeaways

- 😀 Driving a car involves various actions like adjusting speed using the gas or brake pedals, steering, and monitoring the fuel level.

- 😀 These actions in driving are examples of control functions that ensure safe and efficient vehicle operation.

- 😀 In industrial settings, control systems are also used to ensure processes run safely and efficiently, just like in driving a car.

- 😀 Control systems in industries are essential for safety, meeting product specifications, and improving efficiency.

- 😀 Industrial control systems consist of three main components: measurement elements, controllers, and output devices (actuators).

- 😀 Measurement elements (like gauges and sensors) collect data and send it to the controller to regulate the process.

- 😀 Controllers compare the collected data with set targets and send signals to actuators to make adjustments in the process.

- 😀 Modern industrial controllers rely on computer systems rather than traditional pneumatic or hydraulic methods.

- 😀 Actuators make physical adjustments to processes based on the controller's signals to ensure that target parameters are achieved.

- 😀 While automated control systems are preferred in large-scale operations, manual control is still used in smaller industries for flexibility in production.

- 😀 Automation is crucial for processes requiring consistency, like in oil refineries, where operations run 24/7 to produce large volumes of products.

Q & A

What is the primary purpose of the control function in the automotive context as mentioned in the script?

-The primary purpose of the control function in the automotive context is to ensure safe and efficient driving by managing vehicle speed, steering, fuel levels, and other components like brakes and gas pedals.

How is the control function in industrial systems similar to the controls in a car?

-In both automotive and industrial systems, control functions ensure that parameters remain within set limits. Just like speedometers, gas pedals, and steering wheels in a car help control the vehicle, industrial control systems use various components to regulate production processes.

Why is safety a critical reason for implementing control systems in industries?

-Safety is essential because control systems prevent processes from exceeding dangerous levels. They ensure that operations remain within safe limits, preventing accidents and maintaining operational safety.

What are the three main components of a control system in industrial settings?

-The three main components of an industrial control system are the measurement element, the controller (or regulator), and the final output device (actuator).

How do measurement elements in industrial systems work?

-Measurement elements, like sensors and gauges, gather data from various points in the process, which is then transmitted to the controller for regulation.

What role does the controller play in an industrial control system?

-The controller receives data from the measurement elements, compares it to a set target (setpoint), and sends signals to actuators to adjust the process to meet the desired parameters.

What is the function of actuators in a control system?

-Actuators adjust the process by taking action based on the signals from the controller. They modify parameters such as pressure, temperature, or flow within the system.

How has the role of controllers evolved in modern industries?

-In modern industries, controllers have shifted from mechanical systems using air pipes and hydraulics to more advanced computer-based systems, increasing precision and flexibility.

Why might smaller industries still rely on manual control systems?

-Smaller industries or those with less complex production processes may rely on manual control systems because they offer greater flexibility, allowing operators to adjust processes more easily to produce different product variations.

What is the advantage of automated control systems compared to manual systems?

-Automated control systems provide greater consistency in output, making them ideal for large-scale processes where product uniformity is crucial, such as in refineries, which operate continuously and produce large volumes.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

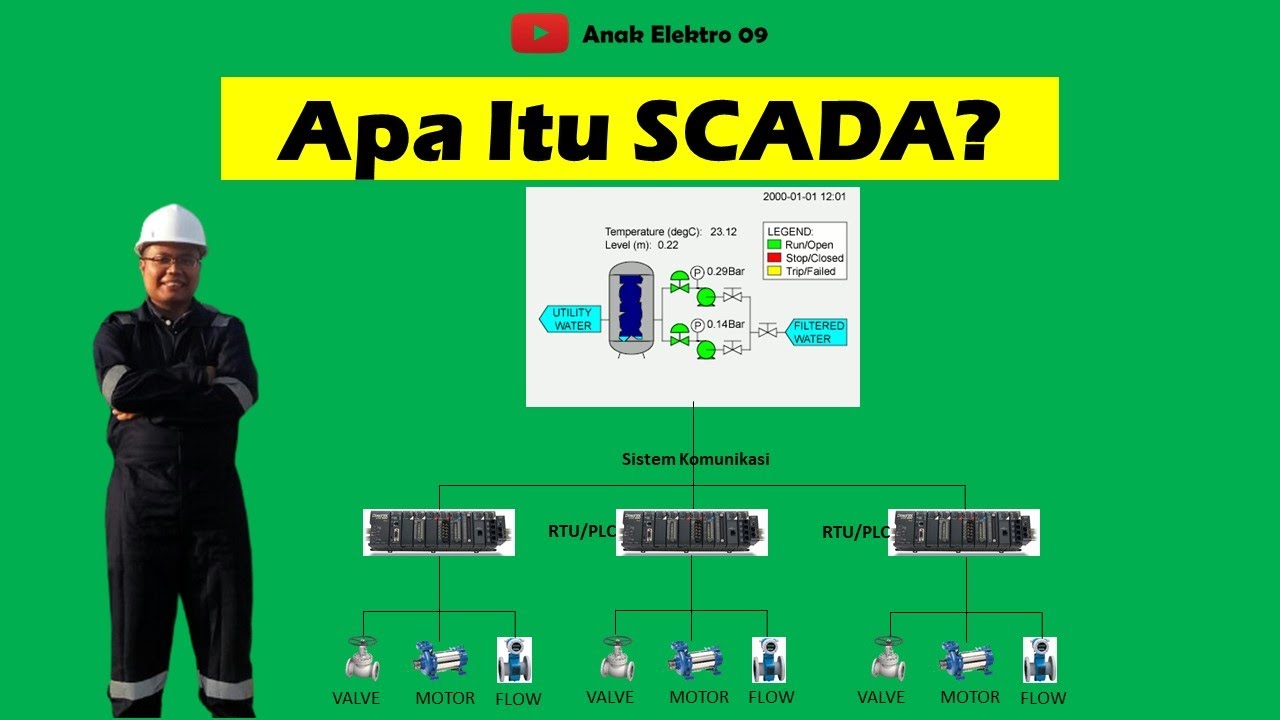

Pengenalan SCADA (Supervisory Control And Data Acquisition)

Industrial Actuators Types of Actuators Actuator Working Principle Actuator Control Methods PLC

SISTEM KONTROL DALAM OTOMASI INDUSTRI

What is Mechatronics? Let's Get to Know the Basic Components and How They Work! Simple Tutorial E...

AWAL BELAJAR Ngobrol Santai Tentang PLC (Programmable Logic Controller)

1. Introduction - Process Control Instrumentation -

5.0 / 5 (0 votes)