Industrial Actuators Types of Actuators Actuator Working Principle Actuator Control Methods PLC

Summary

TLDRThis video explores the role of industrial actuators in automation systems. Actuators convert energy into mechanical movement, driving processes from opening valves to powering robotic arms. The video covers key actuator types, including electric, pneumatic, hydraulic, and mechanical actuators, along with their working principles. It also explains how PLCs control actuators using digital, analog, and PWM signals. Real-world applications like conveyor belts, robotic arms, and CNC machines highlight the importance of actuators in industrial automation, ensuring precise and efficient control of machinery and systems.

Takeaways

- 😀 Actuators convert energy into mechanical movement, either linear or rotary, and are essential in industrial automation systems.

- 😀 Actuators require two main components: a power source (electricity, air, fluid, or mechanical) and a control signal (usually from a PLC).

- 😀 Electric actuators use electricity to produce precise motion, often powered by AC or DC motors and utilizing gears like worm or planetary gears.

- 😀 Pneumatic actuators use compressed air to create movement, with common types being single-acting and double-acting actuators.

- 😀 Hydraulic actuators generate powerful motion using fluid pressure, ideal for heavy-duty tasks, with both linear and rotary variants.

- 😀 Mechanical actuators convert rotary motion into linear movement using mechanisms like gears, screws, levers, or cams.

- 😀 PLCs control actuators through various methods: digital signals (on/off control), analog signals (for precise positioning), and pulse width modulation (PWM) for speed control.

- 😀 Digital signal control is used for simple on/off control, such as operating solenoid valves or pneumatic cylinders.

- 😀 Analog signal control allows for variable output, like adjusting a valve to specific positions (e.g., 25%, 50%, 75%).

- 😀 PWM is used for precise control of actuators like DC motors, where the signal adjusts motor speed based on the desired performance.

- 😀 Real-world applications of actuators include conveyor belts in packaging plants, robotic arms in manufacturing, pneumatic cylinders in material handling, and CNC machines for precision cutting.

Q & A

What is an actuator and what role does it play in industrial automation?

-An actuator is a device that converts energy into mechanical movement, either linear or rotary. In industrial automation, actuators work as the output mechanism, converting control commands into physical actions, enabling systems to perform specific tasks like opening valves or powering robotic arms.

What are the main types of actuators used in industrial automation?

-The main types of actuators in industrial automation are electric, pneumatic, hydraulic, and mechanical actuators. Each type is suited for specific tasks and offers distinct benefits in terms of force, speed, and control.

How do electric actuators work?

-Electric actuators work by using an electric motor, typically either AC or DC, to convert electrical energy into rotational motion. This motion is then transmitted through gears to produce linear or rotary movement.

What are the differences between single-acting and double-acting pneumatic actuators?

-Single-acting pneumatic actuators use compressed air in one direction, while a spring or similar mechanism returns the actuator to its starting position. Double-acting pneumatic actuators use compressed air in both directions, allowing for controlled movement in both extension and retraction.

Why are hydraulic actuators often used for heavy-duty tasks?

-Hydraulic actuators are ideal for heavy-duty tasks because they use fluid pressure, typically oil, to generate strong forces. This makes them capable of handling large loads and performing high-force applications, such as lifting or pushing heavy machinery.

How do PLCs control actuators in industrial automation?

-PLCs control actuators by sending output signals that activate the actuator. These signals can be digital (on/off), analog (to control positions or speeds), or PWM (to control speed or power more precisely). PLCs use relays, contactors, and other output devices to communicate with actuators.

What is Pulse Width Modulation (PWM) and how is it used in actuator control?

-Pulse Width Modulation (PWM) is a method used to control the speed of DC motors. By adjusting the duration of the pulse, it controls how much power is sent to the motor, allowing for fine-tuned control of the motor's speed or operation.

What is the difference between digital and analog control methods for actuators?

-In digital control, actuators operate in binary states (on/off), commonly used for simple tasks like opening or closing valves. In analog control, actuators can be positioned at varying levels, such as partially open, using signals that vary continuously (e.g., 4-20mA or 0-10V).

What are some common applications of industrial actuators?

-Common applications of industrial actuators include controlling conveyor belts in packaging plants, robotic arms in automotive manufacturing, managing valves in chemical plants, operating pneumatic cylinders in material handling, and driving CNC machines for precise machining.

What are mechanical actuators and how do they differ from other types?

-Mechanical actuators convert rotary motion into linear motion using mechanisms like gears, screws, or levers. Unlike electric, pneumatic, or hydraulic actuators, mechanical actuators rely on mechanical force and often don't require external power sources like electricity or air pressure.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

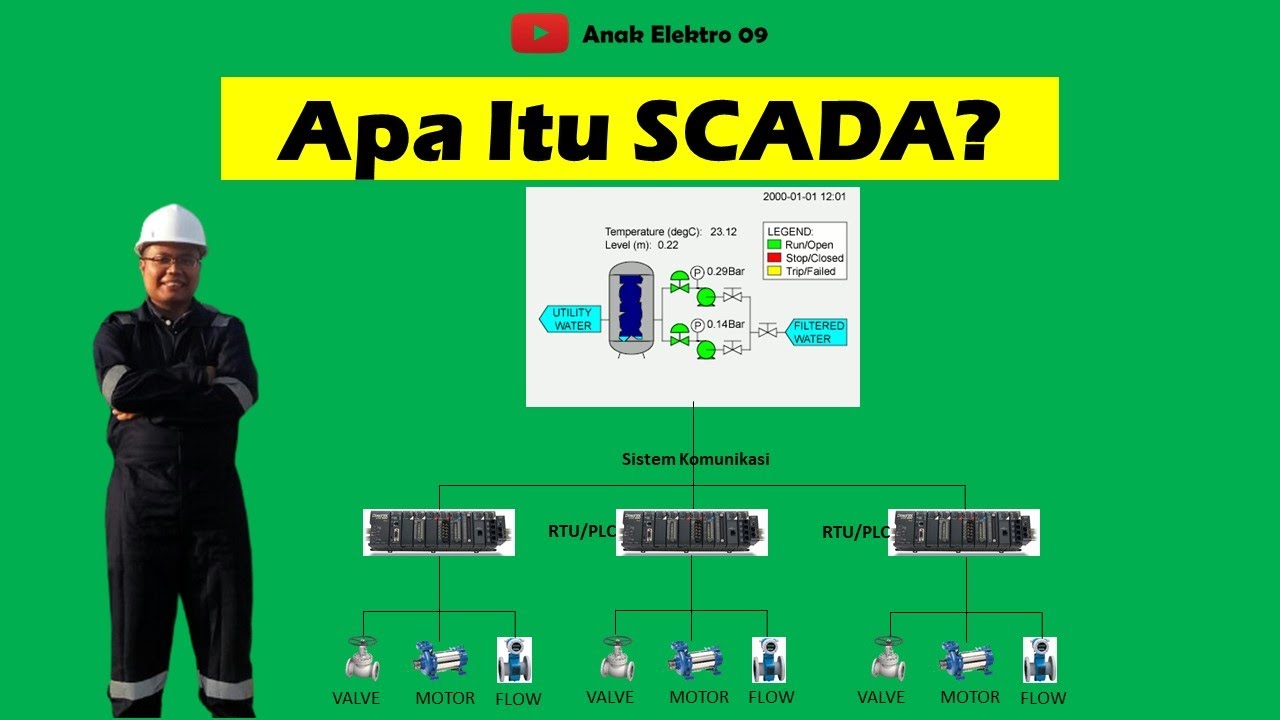

Pengenalan SCADA (Supervisory Control And Data Acquisition)

Pertemuan 3. Sistem Kendali Pada Robot | Robotic and Control System

What are the different types of Actuators - Hydraulic, Rotary, and Electric Linear Actuators

SISTEM KONTROL DALAM OTOMASI INDUSTRI

Pengantar Otomasi Industri

Sensor dan Aktuator

5.0 / 5 (0 votes)