CARA MENGENOLKAN BENDA KERJA MESIN FRAIS || TUGAS PSAJ BAHASA INDONESIA

Summary

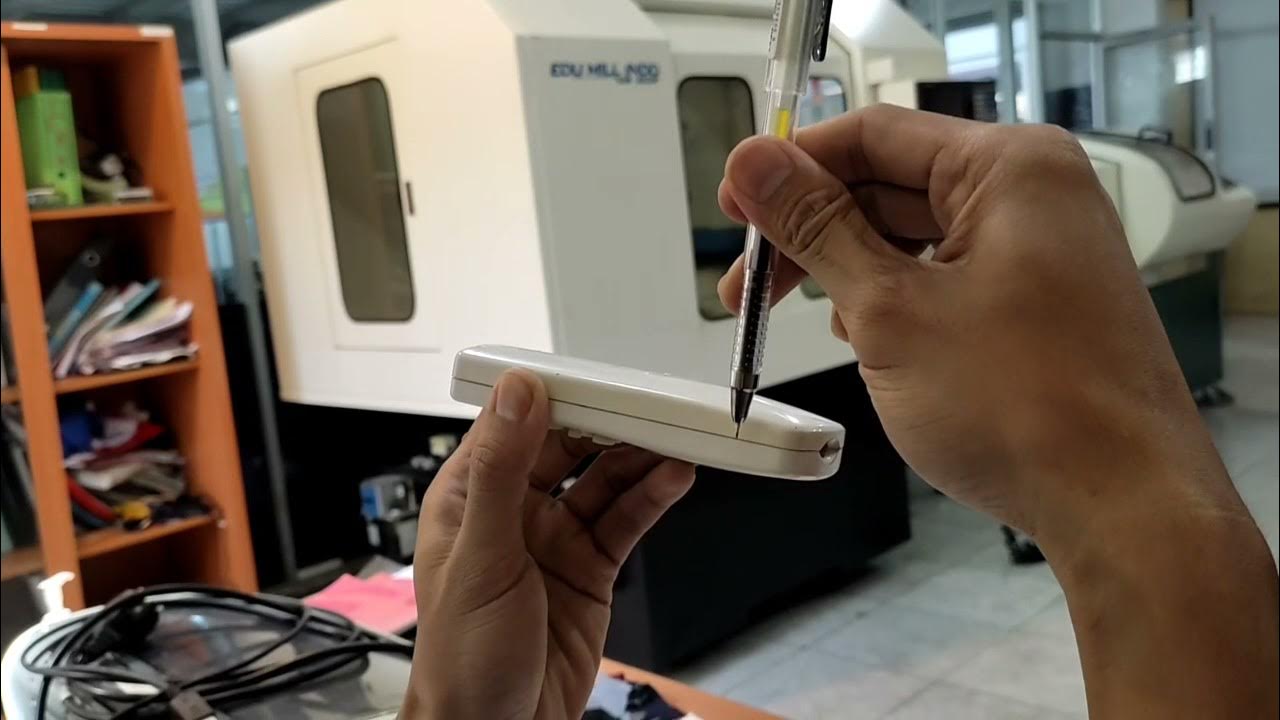

TLDRThis video tutorial demonstrates how to find the zero point (titik nol) of a workpiece in a milling machine. The process involves using tools such as the workpiece, parallel blocks, hammer, and key for securing the vise. The steps include setting up the workpiece, checking for accuracy, and adjusting the machine to ensure precision. The tutorial also explains how to use a small dampened paper to test the setup, making sure the workpiece remains stationary. The goal of the video is to ensure accuracy in milling to avoid errors in the machining process, fulfilling a requirement for Indonesian language and vocational education.

Takeaways

- 😀 The purpose of the video is to demonstrate how to set the zero point or datum on a workpiece using a milling machine for accurate machining and graduation purposes.

- 😀 The main tools required for this process are the workpiece, parallel blocks, a hammer, and a key to tighten the vice.

- 😀 The first step is to open the vice using the key and place the parallel blocks in between the vice jaws.

- 😀 After placing the workpiece on top of the parallel blocks, tighten the vice to prevent any movement of the workpiece.

- 😀 If the parallel block is unstable or shakes, it should be gently tapped with a hammer to secure it in place.

- 😀 A speed of 800 RPM is used for the milling process, with specific direction instructions for the tool movement.

- 😀 A small piece of wet paper is used to cover the workpiece's surface, and the end mill is directed towards it.

- 😀 The paper should move or shift slightly as the end mill approaches, indicating that the tool is touching the surface.

- 😀 Once the paper is displaced, the milling tool should be moved away from the workpiece, and the machine is turned off.

- 😀 The same process is applied for setting the zero point on the side surface of the workpiece, ensuring accurate measurements.

- 😀 The video concludes with the speaker apologizing for any mistakes made during the demonstration and thanking the viewers.

Q & A

What is the primary goal of the video?

-The primary goal of the video is to demonstrate how to find the zero point ('titik nol') on a workpiece using a milling machine, ensuring accuracy and precision in the machining process.

Why is zeroing the workpiece important in milling?

-Zeroing the workpiece is crucial because it ensures the correct alignment and accuracy during machining, preventing errors such as uneven cutting or misalignment, which could lead to defects in the workpiece.

What tools are required for the process shown in the video?

-The tools required include the workpiece, parallel blocks, a hammer, and a key to tighten the vice.

What is the first step in preparing the workpiece for milling?

-The first step is to open the vice using the key, place the parallel blocks between the vice jaws, and then position the workpiece on top of the parallel blocks.

How can you check if the parallel blocks are properly set up?

-To check if the parallel blocks are set properly, gently tap them with a hammer. If they stop shaking, it indicates that they are firmly in place.

What speed setting is used in the video for the milling machine?

-The milling machine speed setting used in the video is 800 RPM.

What is the purpose of placing a damp piece of paper on the workpiece?

-The damp paper is used to detect any slight movement or misalignment of the mill during the process. If the paper moves, it indicates that the mill has made contact with the surface.

What should be done after the paper moves during the milling process?

-After the paper moves, the mill should be freed from the workpiece, and the milling machine should be turned off.

How does the process of zeroing the side surface of the workpiece differ from zeroing the top surface?

-The process for zeroing the side surface is similar to zeroing the top surface, but instead of placing the damp paper on top, it is placed on the side of the workpiece, and the mill is directed towards the paper.

What is the significance of the video for the presenter’s academic requirements?

-The video is a requirement for the presenter to pass their Indonesian Language and Culture (Bahasa Indonesia) subject, demonstrating both their technical knowledge and communication skills in explaining the milling process.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)