iQ - R MES Interface | Mitsubishi Electric

Summary

TLDRIn this episode of the Mi Workshop series, Miow demonstrates how to integrate control systems with databases using the MEES interface module on the MEL IQR platform. He walks viewers through the setup of PLCs, network settings, and database connections, showcasing how the MEES module ensures seamless communication between the OT and IT layers. With easy configuration and buffering capabilities to handle connection loss, the system supports up to 64 PLCs and various manufacturers. The tutorial covers data insertion, selection, and updates in the database, making it accessible even to users with limited database knowledge.

Takeaways

- 😀 The Mees Interface module on the MEL IQR platform helps link production and process data with upper systems.

- 😀 The module features two independent Ethernet ports for IT and OT layer separation and an SD card slot for caching database queries during communication loss.

- 😀 The Mees module automatically sends buffered data back to the database once the connection is restored after a loss.

- 😀 The configuration of the system can be done easily using GX Works 3, Microsoft SQL Server Management Studio, and the Mees Interface Function Configuration Tool.

- 😀 In the configuration, you can set up up to 64 PLC devices, supporting various manufacturers such as Mitsubishi, Rockwell, and others.

- 😀 The module allows for both service and direct DB connections with the database, making integration flexible and accessible.

- 😀 Users can configure the connection between the PLC and the Mees module, with specific settings like network IP addresses and database buffer configurations.

- 😀 The system supports SQL Server 2019, and users can connect to their databases using secure credentials like usernames and passwords.

- 😀 Through the Mees Configuration Tool, users can add up to 64 database tables and automatically map fields between the database and the PLC.

- 😀 The system allows for data operations like insert, select, and update, making it versatile for different database interactions.

- 😀 Data selection and updates are executed with precise conditions such as ID filtering and sorting, ensuring accurate database manipulation.

- 😀 The system ensures the integrity of data even during connection disruptions by automatically buffering and restoring lost queries.

Q & A

What is the focus of the Miow Workshop series episode discussed in the script?

-The episode focuses on the integration of control systems and database systems in industrial automation, specifically how the Mees Interface module on the Mel IQR platform helps link production and process data with upper-level systems.

How does the Mees Interface module help maintain data integrity during database connection issues?

-The Mees Interface module is equipped with an SD card slot that allows it to cache database queries if the connection is lost. It then automatically sends the data back to the database once the communication is restored.

What software tools are used in the demonstration for configuring the Mees Interface module?

-The demonstration uses GX Works 3 software for configuration, Microsoft SQL Management Studio for managing the database, and the Mees Interface Function Configuration Tool for setting up the connection between the PLC and the database.

What is the purpose of the Target Device Setting in the Mees Interface Function Configuration Tool?

-The Target Device Setting allows users to configure which PLC will be connected to the Mees Interface module, and it supports up to 64 devices, including Mitsubishi Electric PLCs and other manufacturers' PLCs with an additional license.

How does the Mees Interface module handle buffer settings for database queries?

-The module uses DB buffer settings to store database queries when the connection to the database is lost. Once the connection is re-established, the module sends all the stored queries back to the database without losing any data.

How many tables can the Mees Interface module connect to within a single project?

-The Mees Interface module can connect to up to 64 tables within a single project.

What steps are involved in configuring the connection between the Mees Interface module and the database?

-The configuration involves setting the IP address of the module, selecting the database type (e.g., SQL Server 2019), entering the database credentials, and then linking the module with the database tables and fields to enable data operations.

What types of database operations can be performed using the Mees Interface module?

-The Mees Interface module supports several database operations, including Insert, Select, Update, and Delete. It also allows executing stored procedures within the database.

How does the Mees Interface module handle high-speed data access?

-The Mees Interface module offers various access speeds, including high-speed access, which allows for data retrieval from the PLC at intervals as short as 1 millisecond. Users can choose the desired speed based on their application needs.

What happens if the connection between the Mees Interface module and the database is lost during an operation?

-If the connection is lost, the module will buffer the database operations and queries. Once the connection is restored, it will automatically send the buffered data to the database, ensuring no data is lost.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

LLM Module 3 - Multi-stage Reasoning | 3.2 Module Overview

4.3 Excreta Management in Emegencies

Microservices Architecture Patterns | SAGA Choreography Explained & Project Creation | JavaTechie

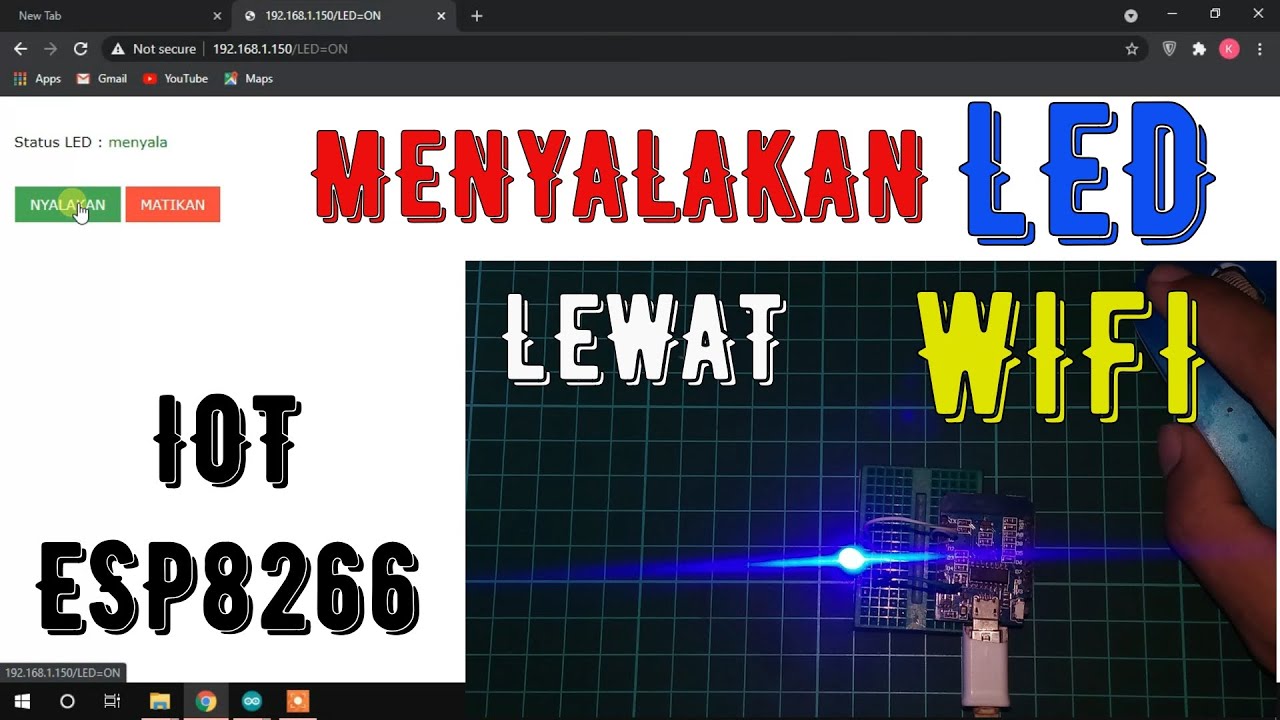

MENYALAKAN LED LEWAT WIFI | ESP8266 | IOT | MENYALAKAN LAMPU LEWAT INTERNET

Fulfillment: How to Integrate Dialogflow with Google Calendar

INTEGRATION OF SENSOR AND ACTUATORS WITH ARDUINO-I

5.0 / 5 (0 votes)