Crude Distillation Unit

Summary

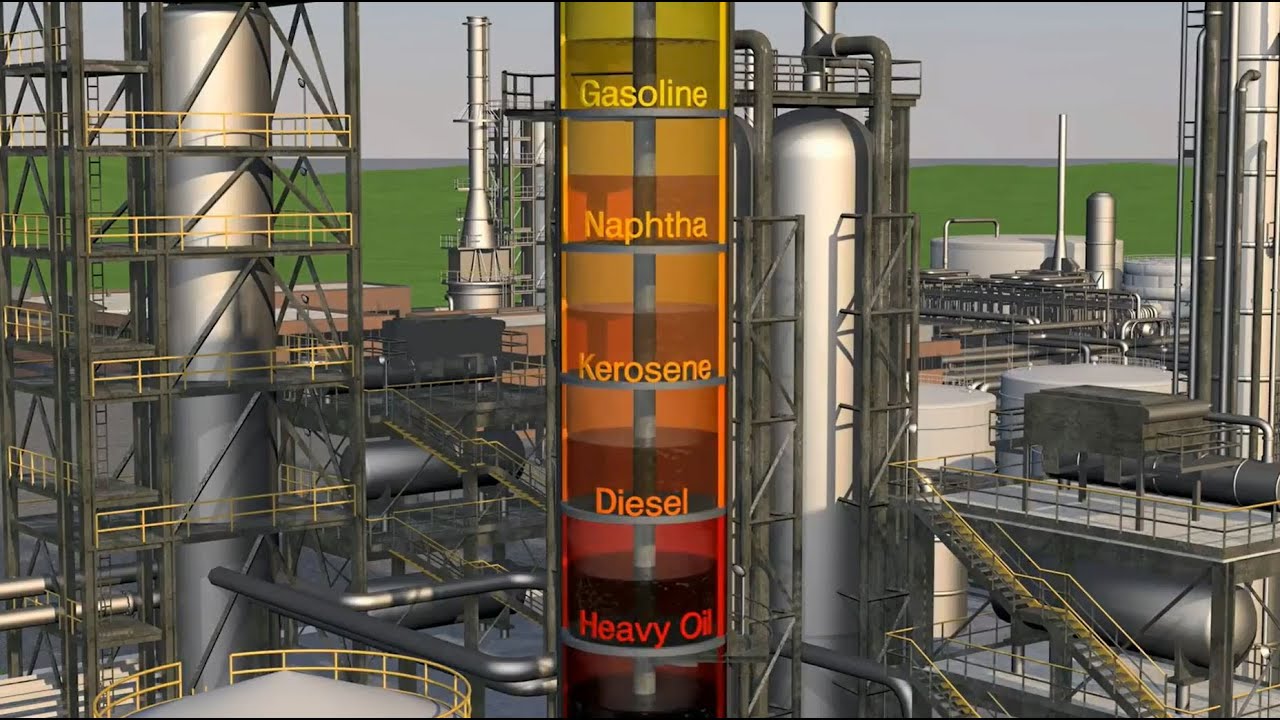

TLDRThis script provides an in-depth explanation of the atmospheric distillation process in an oil refinery. It covers the essential steps involved, such as crude oil processing, separation via distillation, and the production of various products like gasoline, kerosene, diesel, and other fuels. The script also highlights the equipment used, such as heat exchangers and electrostatic desalting units, emphasizing the efficiency and cost-effectiveness of the process. With a focus on distillation columns and the principles behind oil separation, the content offers a technical yet accessible overview of how crude oil is refined into usable products.

Takeaways

- 😀 The Atmospheric Tessellation Unit is a key component in the petroleum refinery process, designed to handle crude oil for further refinement.

- 😀 The distillation unit separates crude oil into fractions based on boiling points using atmospheric pressure for initial separation and vacuum distillation for high-boiling fractions.

- 😀 Distillation units in refineries vary in capacity, ranging from 10,000 tons to 400,000 tons per day.

- 😀 The main products produced in the distillation unit include gases, naphtha, kerosene, diesel, and atmospheric gas oil.

- 😀 Crude oil undergoes desalting to remove dissolved salts and water before entering the distillation process, using electrostatic water separation.

- 😀 The distillation unit uses heat exchangers to raise the temperature of the oil, and the oil is partially vaporized in the stripping section of the column.

- 😀 A key part of the distillation process is the injection of steam in the stripping section to aid in separation and improve efficiency.

- 😀 The process includes controlling the boiling point of various fractions, using trays to separate products, and having specific trays for different types of oil products.

- 😀 Overhead vapor from the distillation column is condensed to produce liquid products like light naphtha, which is then recycled back to the column for further separation.

- 😀 The distillation column in Indonesia has 30-50 trays, each designed for specific types of oil fractions to optimize the separation process.

Q & A

What is the primary function of the Atmospheric Distillation Unit in an oil refinery?

-The Atmospheric Distillation Unit is primarily used to separate crude oil into different fractions based on their boiling points. This is the first step in the oil refining process, where crude oil is processed before further refinement in downstream units.

What are the different types of products produced in the Atmospheric Distillation Unit?

-The main products produced in the Atmospheric Distillation Unit include gases, light naphtha (used as gasoline or jet fuel), kerosene (used as jet fuel), middle distillates like diesel, gas oil, and atmospheric residues.

What is the typical capacity range for a distillation unit?

-The typical capacity for a distillation unit ranges from 10,000 barrels per day (bpd) or 1,450 tons per day to 400,000 barrels per day (bpd) or 56,000 metric tons per day.

How does the Atmospheric Distillation Unit separate crude oil?

-The crude oil is heated and then passed through a distillation column where it is separated into various fractions based on their boiling points. The process utilizes both atmospheric pressure for lighter fractions and vacuum conditions for heavier fractions.

What role does desalting play in the distillation process?

-Desalting removes water and salts that are dissolved in the crude oil, using an electrostatic water separation process. This step is important because salts can form emulsion with water, which cannot be separated by simple mechanical or gravitational methods.

What are some of the key temperature conditions during the distillation process?

-The oil is typically heated to temperatures between 120-150 degrees Celsius before entering the distillation column. During distillation, the fractions are separated at various temperatures depending on their boiling points.

Why is steam injected into the bottom of the distillation column?

-Steam is injected into the bottom of the distillation column to help vaporize the heavier fractions of crude oil. This assists in separating the various components more efficiently by providing the necessary heat for the distillation process.

What is the role of the trays inside the distillation column?

-The trays inside the distillation column are designed to separate the different fractions of crude oil based on their boiling points. The vapor condenses on these trays, allowing the heavier fractions to drop to the lower trays while lighter fractions rise.

What is the significance of vacuum conditions in the distillation process?

-Vacuum conditions are used in the distillation process for separating heavier fractions that have high boiling points. By reducing the pressure in the column, the boiling points of these heavy fractions decrease, allowing them to be separated at lower temperatures.

How does the distillation unit contribute to downstream processing in a refinery?

-The distillation unit produces different fractions that are then sent to downstream units for further processing. These fractions are refined into specific products such as gasoline, kerosene, diesel, and other petroleum products that meet industry specifications.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)