Penyumbang Emisi Karbon, Mungkinkah Indonesia Memproduksi Semen Hijau?

Summary

TLDRCement production is a major contributor to global CO2 emissions, primarily due to the energy-intensive process of making clinker. Efforts to reduce emissions in the cement industry include utilizing carbon capture and storage (CCS) technologies, replacing clinker with alternative materials, and developing green cement, which can reduce emissions by up to 40%. While the decarbonization of cement production is costly, with price increases of up to 30% in some cases, it can have minimal impact on the final cost of concrete. Global initiatives, including in Indonesia, aim to achieve emissions reduction targets to mitigate climate change.

Takeaways

- 😀 Cement production is the largest emitter of CO2, not the transportation sector, due to its energy-intensive processes.

- 😀 The main components of cement production include calcium oxide, silica, alumina, and iron oxide, which contribute to CO2 emissions.

- 😀 Historically, cement has negatively impacted the environment due to the high CO2 emissions from the production process, especially from heating materials at very high temperatures.

- 😀 For every ton of cement produced, approximately one ton of CO2 is released into the atmosphere, directly contributing to global warming.

- 😀 The cement industry faces a significant challenge in reducing CO2 emissions while meeting the global demand for infrastructure, especially in developing countries.

- 😀 Innovations such as carbon capture and storage (CCS) and the use of low-carbon fuels are being explored to reduce emissions from cement production.

- 😀 Green cement is an environmentally friendly alternative that significantly reduces CO2 emissions during production, with reductions of up to 40%.

- 😀 To decarbonize the cement industry, efforts must focus on operational efficiency, technological innovation, and business model reorientation.

- 😀 The cement industry is aiming to reduce CO2 emissions by 4% annually until 2030 to align with global net-zero emission targets by 2050.

- 😀 Carbon capture, utilization, and storage (CCUS) is a promising technology for capturing CO2 emissions and potentially achieving net-zero emissions in clinker production.

- 😀 Despite its potential, CCUS is costly and still unproven at a large scale, making the technology challenging to implement across the industry.

Q & A

What is the primary source of CO2 emissions in the cement industry?

-The primary source of CO2 emissions in the cement industry comes from the production of clinker, the key component in cement, which releases a significant amount of CO2 during the heating process.

How does cement production impact climate change?

-Cement production contributes to climate change by releasing CO2 into the atmosphere. For every ton of cement produced, approximately one ton of CO2 is released, which directly correlates with global temperature rise.

Why is cement production considered one of the largest sources of CO2 emissions?

-Cement production is one of the largest sources of CO2 emissions due to the energy-intensive process of heating limestone (clinker) at extremely high temperatures, typically requiring large amounts of coal or natural gas, which release CO2.

What role does green cement play in reducing emissions?

-Green cement plays a crucial role in reducing emissions by significantly lowering the CO2 released during production. The process can reduce emissions by up to 40%, making it a more environmentally friendly alternative to traditional cement.

What challenges does the cement industry face in reducing CO2 emissions?

-The cement industry faces challenges such as maintaining production levels to meet global infrastructure demands while also reducing CO2 emissions. Key obstacles include the cost of adopting carbon capture technologies and the need to find alternative materials that can replace clinker.

What is the carbon capture and storage (CCUS) technology, and how does it help the cement industry?

-Carbon capture and storage (CCUS) is a technology that captures CO2 emissions from industrial processes, preventing them from entering the atmosphere. In the cement industry, it can significantly reduce CO2 emissions by capturing and storing the CO2 produced during clinker manufacturing.

How might carbon capture and storage (CCUS) impact cement production costs?

-CCUS could increase the cost of cement production due to the high expense of capturing, transporting, and storing CO2. While it offers environmental benefits, the technology is still expensive and not widely proven on a large scale.

What is the expected impact of de-carbonizing the cement industry on cement prices?

-De-carbonizing the cement industry is expected to significantly increase production costs, potentially raising the price of cement by more than 100 USD per ton, which could lead to a 30% increase in concrete costs, although the impact on consumers would be around 3%.

What are some innovative materials being explored to reduce the environmental impact of cement?

-Innovative materials such as saltwater from desalination plants and slag from steel production are being explored as alternatives to traditional cement. These materials aim to reduce or eliminate the need for clinker, thereby reducing CO2 emissions.

How does the global cement industry aim to meet climate goals?

-The global cement industry is working to meet climate goals by reducing emissions by 4% annually until 2030. This involves improving operational efficiency, adopting new technologies like carbon capture, and exploring alternative materials to replace clinker.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Let's Talk Global Warming Episode 2: Carbon Dioxide

Decarbonising steel making with new technologies

Reducing the Carbon Footprint of Cement Production

Cement Manufacturing Process with the Portland Cement Association

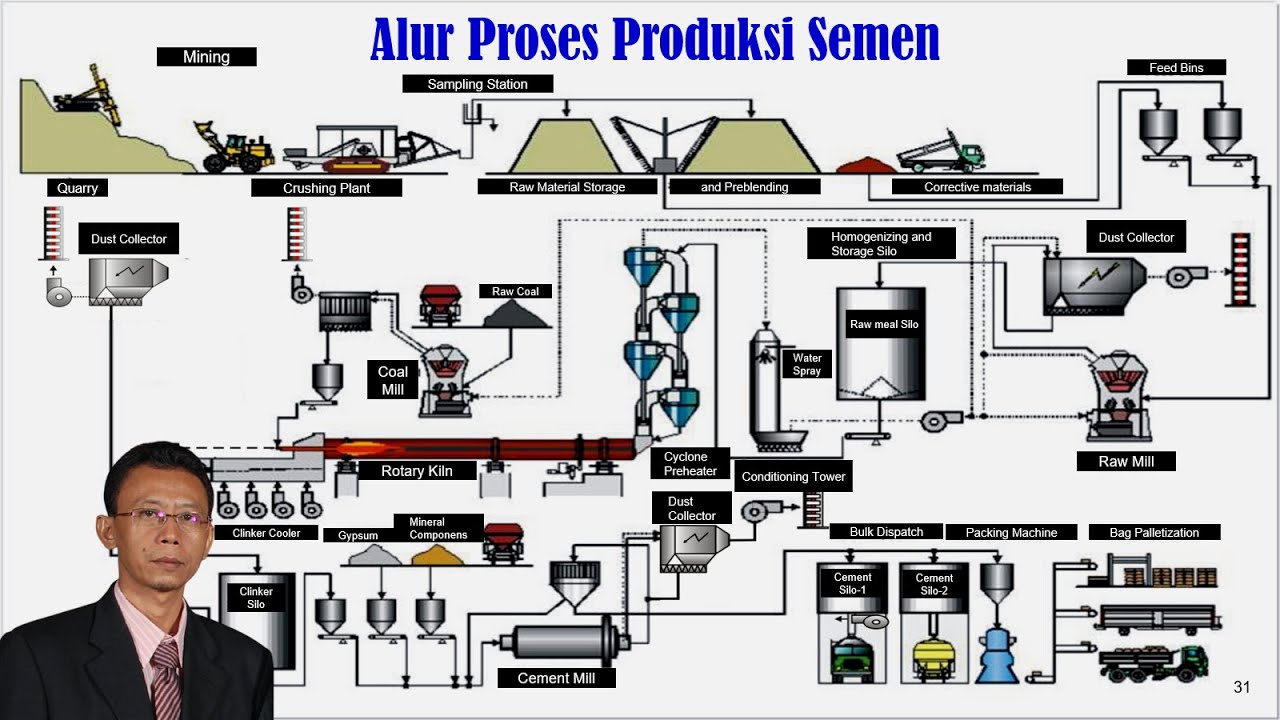

Alur Proses Produksi Semen (Tahapan Proses Produksi Semen)_Indonesia

High Tech Concrete (Intro to Solid-State Chemistry)

5.0 / 5 (0 votes)