Stratix Industrial Switch 01 - Why Managed Switches

Summary

TLDRThis video discusses the importance of managed switches in industrial environments, particularly in plant systems. It covers the challenges of evolving from legacy protocols to Ethernet, highlighting the need for segmentation and network resilience. The script explains VLANs for better traffic control, redundancy protocols for minimizing network downtime, and strategies like network address translation to handle IP conflicts. It also touches on security, diagnostics, and management features of modern switches, emphasizing their role in maintaining uptime, security, and efficient system performance in high-demand industrial settings.

Takeaways

- 😀 Ethernet networks in industrial systems have evolved from legacy protocols like DH+ and Remote I/O, leading to challenges in configuration and troubleshooting.

- 😀 Legacy systems offered natural segmentation, isolating failures to specific areas, but this has been lost in modern flat networks.

- 😀 Managed switches help restore network segmentation using VLANs, isolating traffic and preventing system-wide failures when a device malfunctions.

- 😀 The use of VLANs allows for better control over network traffic, providing more flexibility in managing different devices or traffic types.

- 😀 Redundancy in industrial networks is crucial to avoid downtime. Managed switches provide resiliency protocols like Spanning Tree and Resilient Ethernet to ensure uptime even if a device or cable fails.

- 😀 Managed switches enable device-level redundancy (DLR), where devices are daisy-chained to reduce reliance on individual switch ports and improve overall resilience.

- 😀 IP address management in industrial systems can lead to conflicts, but Network Address Translation (NAT) helps manage duplicate IP addresses and ensures smooth communication across the network.

- 😀 Security is enhanced by managed switches, which allow for blocking unauthorized devices or users and provide granular control over network access.

- 😀 Managed switches can automatically assign IP addresses through DHCP, simplifying network configuration and reducing manual intervention.

- 😀 Built-in diagnostic features in managed switches help identify and troubleshoot network and device issues, improving overall system reliability.

- 😀 Traffic prioritization is essential in industrial networks, and managed switches allow prioritizing time-sensitive traffic, like motion control systems, to ensure critical data is transmitted on time.

Q & A

Why were legacy Ethernet protocols like DH+ and remote I/O challenging in industrial environments?

-Legacy Ethernet protocols such as DH+ and remote I/O were difficult to configure and troubleshoot due to their proprietary nature, which often required specialized knowledge and tools. Additionally, these protocols didn't easily integrate with modern automation systems, creating compatibility challenges.

What is the primary issue when a network evolves without proper planning?

-When a network evolves without proper planning, it can become a 'flat network' where everything is connected at the same level. This can cause a single device failure to potentially bring down the entire network, as there is no segmentation to isolate faults.

How does a VLAN help manage network traffic in industrial environments?

-A VLAN (Virtual Local Area Network) allows devices to be logically segmented on the same physical network. This segmentation helps control traffic flow between devices and isolates problems, so issues in one part of the network do not affect the entire system.

What is a common issue with unmanaged switches when using loops for redundancy?

-Unmanaged switches cannot handle network loops properly, which can result in broadcast storms. This occurs when a broadcast packet is sent in a loop, causing it to flood the network and eventually crash the system.

What is Spanning Tree Protocol (STP) and how does it work to prevent network loops?

-Spanning Tree Protocol (STP) prevents network loops by identifying a 'root switch' and calculating the best path for data to travel. It blocks certain ports on switches to ensure that traffic only flows along the correct paths and automatically reactivates the blocked ports if the network topology changes.

What is the advantage of using Resilient Ethernet Protocol (REP) over Spanning Tree Protocol in industrial environments?

-Resilient Ethernet Protocol (REP) is optimized for faster network recovery in industrial environments. It operates in the millisecond range, which is crucial for systems that require low latency and high uptime, like automation networks. Unlike Spanning Tree, REP ensures quicker recovery and minimizes downtime in case of network failure.

What is Device Level Ring (DLR) and how does it help improve network resilience?

-Device Level Ring (DLR) is a redundancy protocol that connects devices in a loop configuration. It provides resilience by allowing devices to maintain network communication even if one of the cables or devices fails. The loop ensures that the network remains functional even if one part of the system goes down.

How does Network Address Translation (NAT) help resolve issues with duplicate IP addresses?

-Network Address Translation (NAT) allows devices with the same IP address to communicate on a network by translating their IP addresses to unique addresses within the switch. This is useful in environments where devices from different vendors may use the same default IP address, preventing network crashes due to IP conflicts.

What security features are available in managed switches to protect industrial networks?

-Managed switches offer several security features such as the ability to block unknown devices, limit user access to certain network activities, and control traffic flow. These features help protect the network from unauthorized access and potential security breaches.

How do managed switches help with diagnostics and network monitoring in industrial settings?

-Managed switches provide built-in diagnostic tools that allow operators to detect physical or network issues. They also offer centralized management, enabling users to monitor the status of all connected devices and easily configure or troubleshoot network settings from a single location.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Unmanaged vs Managed Switches

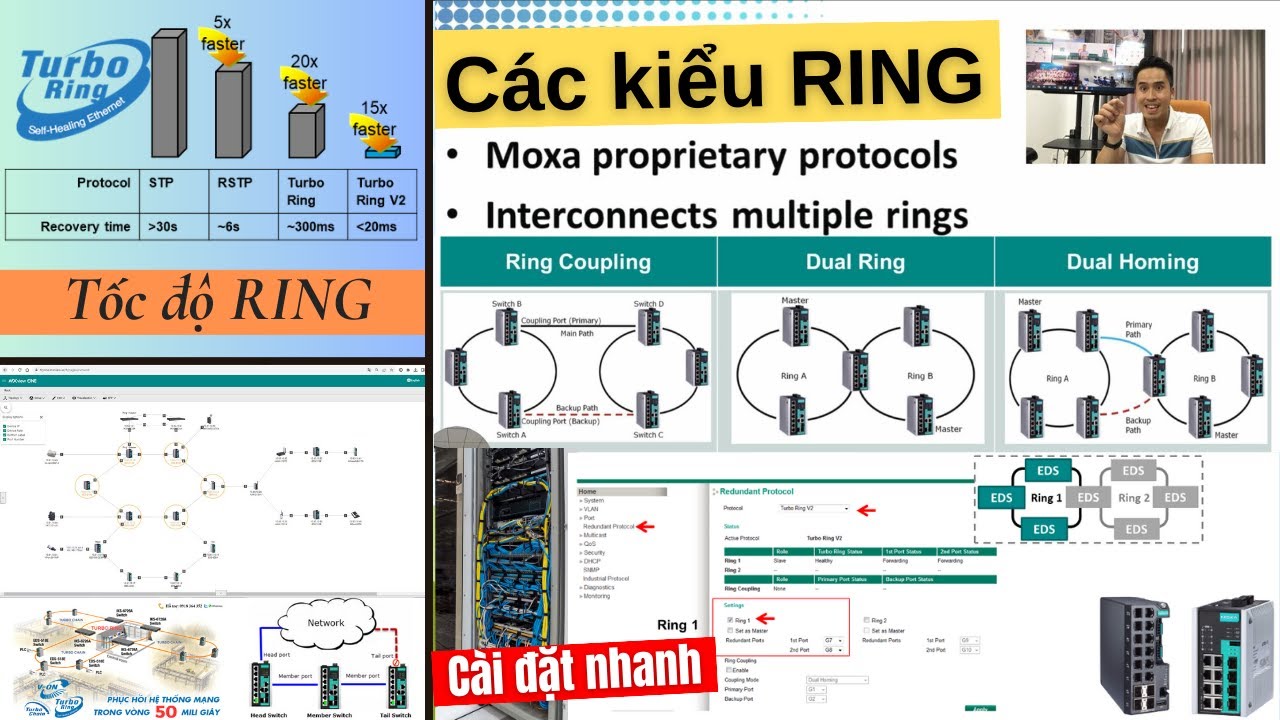

Hồi tiếp mạng TurBo-Ring/Ring-Coupling/Dual Ring/DualHome và Cài Đặt NTN? #moxavietnam

18 - Dry Sprinkler Systems - Introduction to Fire Alarms

Memelihara Peralatan Pneumatik - Teknik Mekatronika

Stratix Industrial Switch - Selecting a Managed Switch

Automated Irrigation Techniques

5.0 / 5 (0 votes)