Tesla Turbine | The interesting physics behind it

Summary

TLDRNikola Tesla's bladeless turbine, also known as the Tesla turbine, is a unique innovation in engineering that challenges traditional turbine designs. Unlike conventional turbines, which rely on airfoil principles and complex blades, the Tesla turbine uses the viscous effect of fluid on solid surfaces to generate motion. While the turbine can achieve high efficiency, especially at high speeds, it faces challenges in large-scale industrial applications due to mechanical limitations. Despite this, Tesla turbines find niche uses in industries requiring high viscosity pumps, like wastewater treatment and petroleum, showcasing their versatility and potential.

Takeaways

- 😀 Nikola Tesla's bladeless turbine, also known as the Tesla turbine, was a highly efficient design that surpassed steam turbines in performance at the time.

- 😀 Unlike traditional turbines with complex blade designs, the Tesla turbine relied on the viscous effect of fluid on solid surfaces to generate motion.

- 😀 Tesla's turbine design was inspired by the movement of fluid over rounded surfaces, like water flowing over stones, which creates viscous force.

- 😀 The Tesla turbine works by introducing fluid tangentially to a set of discs, which causes the fluid to spiral and interact with the discs to generate rotational force.

- 😀 The efficiency of the Tesla turbine increases significantly with higher fluid speeds, which causes the fluid particles to form a spiral path, thus enhancing the torque output.

- 😀 The concept of boundary layers, where fluid particles in close contact with a surface move slower than those farther from it, plays a crucial role in the Tesla turbine's design.

- 😀 Tesla optimized the turbine's efficiency by reducing the distance between the discs, keeping it about twice the boundary layer thickness, ensuring minimal free flow and maximizing shear effects.

- 😀 Despite its unique design, the Tesla turbine faced challenges due to high RPM requirements, with early prototypes failing due to material limitations at high speeds.

- 😀 Although Tesla claimed 97% efficiency for his 6-inch turbine model, it was only viable at lower speeds (under 10,000 RPM), and the claim was likely unrealistic for industrial applications.

- 😀 Modern steam turbines are more than 90% efficient, and despite its advantages, the Tesla turbine has not been widely adopted in power generation due to limitations in RPM and scale.

- 😀 The Tesla turbine does have niche applications, such as in high-viscosity environments like wastewater plants, petroleum industries, and as a reversible pump in certain medical devices like ventricular assistance pumps.

Q & A

What is the Tesla turbine, and how is it different from traditional turbines?

-The Tesla turbine, also known as the bladeless turbine, has a simple design compared to traditional turbines. Unlike conventional turbines with complex blades, the Tesla turbine operates based on the viscous effects of fluid on solid surfaces, rather than relying on airfoil principles or blades to generate lift.

How does the Tesla turbine utilize fluid's viscous force?

-The Tesla turbine relies on the viscous effect of fluid flowing tangentially over the surface of discs. This fluid's interaction with the discs creates a force that causes the discs to spin, in contrast to traditional turbines that use lift forces generated by blades.

What is the role of boundary layers in the Tesla turbine's efficiency?

-The boundary layer phenomenon is crucial for the Tesla turbine's efficiency. The fluid near the surface of the disc forms a stationary layer, while subsequent layers experience a drag force. Tesla designed the turbine's discs to be close enough to each other so the boundary layers overlap, maximizing the shear effects and increasing torque generation.

Why did Tesla's turbine experience mechanical failure at high speeds?

-Tesla's turbine was designed to operate at extremely high speeds, around 35,000 rpm. However, the discs could not withstand the centrifugal forces generated at such high speeds, causing material failure due to warping. Tesla had to reduce the rpm to below 10,000 to prevent this issue.

Why is the Tesla turbine not commonly used in power generation industries today?

-Despite the Tesla turbine's potential efficiency at high speeds, it is not used in power generation industries because modern steam turbines have efficiencies over 90%, and the Tesla turbine requires excessively high rpm to achieve comparable efficiency. Furthermore, achieving such high speeds with large disks (e.g., 2-3 meters in diameter) is not feasible due to engineering limitations like the blade tip velocity reaching Mach numbers that are impractical.

What are the challenges in operating large Tesla turbines at high rpm?

-For large Tesla turbines with disk diameters of 2-3 meters, achieving a high rpm (e.g., 50,000 rpm) would result in blade tip velocities reaching Mach numbers that are much higher than what is currently achievable. The high centrifugal forces would cause mechanical failure and make it impractical to operate such large turbines efficiently.

What was Nikola Tesla's claimed efficiency for his turbine, and how realistic is it?

-Nikola Tesla claimed an efficiency of 97% for his Tesla turbine. However, this claim is considered unrealistic since the turbine could only run efficiently at speeds under 10,000 rpm, which significantly limits its practical applications and efficiency at higher operational scales.

How does the spiral motion of fluid particles benefit the Tesla turbine?

-The spiral motion of fluid particles, caused by the interaction with the spinning discs, increases the contact area between the fluid and the disc. This increases the viscous force exerted on the discs, which in turn improves the turbine's torque generation and efficiency, especially at high speeds.

What kind of applications benefit from the Tesla turbine's design?

-The Tesla turbine is particularly useful in niche applications that require high viscosity fluids, such as wastewater treatment plants, the petroleum industry, and ventricular assistance pumps. Additionally, it can function as a pump in reverse, making it versatile for specific engineering purposes.

What was the design flaw that led to the failure of Tesla's original turbine model?

-The initial design flaw in Tesla's turbine was the inability of the discs to withstand the high centrifugal forces generated at the intended operational speeds. This caused material expansion and disc warping, leading to mechanical failure. Tesla had to reduce the rpm to preserve the structural integrity of the turbine.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

This NEW European Wind Turbine for Home Out Perform PV Solar Panels in 2024?!

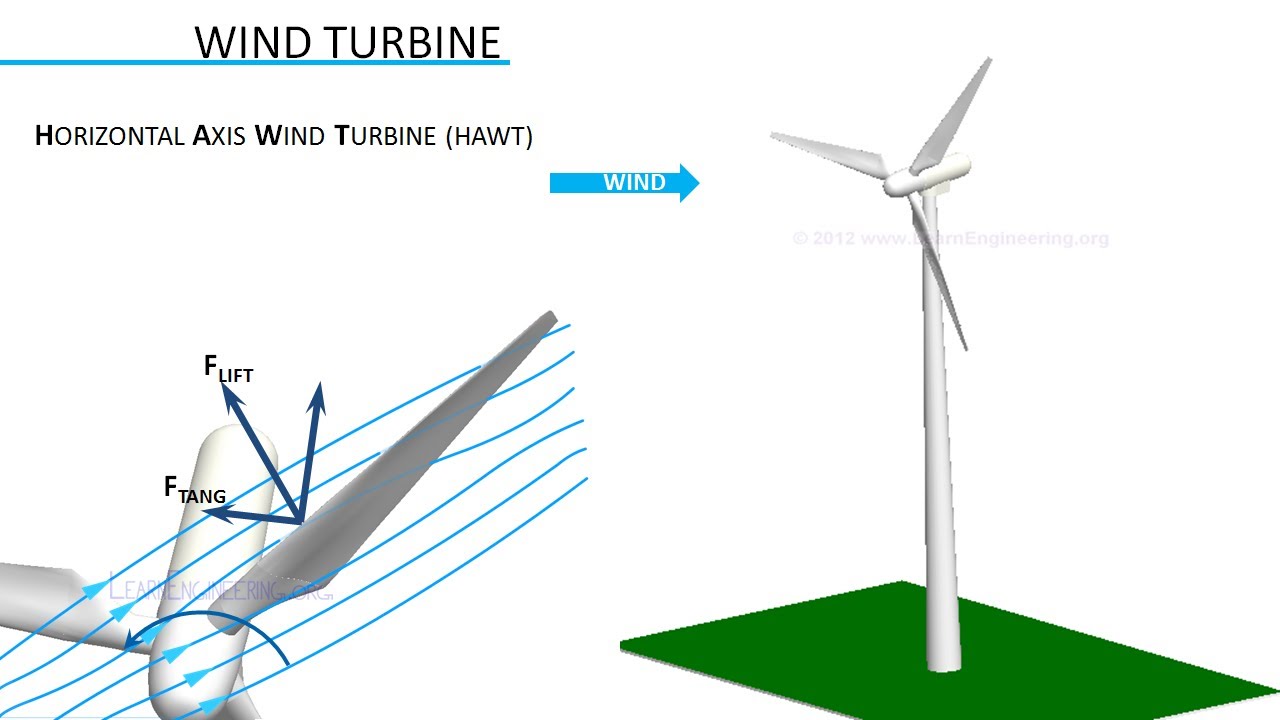

How do Wind Turbines work ?

How to Steam Turbine components work? Power Engineering

lesson 1: steam turbine operation and control with mechanical governor

KONVERSI ENERGI - ENERGI TERBARUKAN (VIDEO 1)

DIY Torquemeter - How to measure torque! [Arduino & 3D Printed]

5.0 / 5 (0 votes)