Optimizing the heat treatment of particulate foods

Summary

TLDRIn the food processing industry, achieving the perfect balance in heat treatment is crucial for creating high-quality, safe products like goulash soup. The challenge lies in heating food containing particles, where too much heat can ruin texture and flavor, while too little risks food safety. By leveraging advanced research and technology, manufacturers can predict and optimize heat transfer, ensuring consistency in processing. With careful calculation and practical trials, food processors can maintain nutritional value, texture, and safety, all while meeting consumer demand for convenience and quality.

Takeaways

- 😀 Consumers demand high-quality, convenient food products in the food processing industry.

- 😀 The food processing industry faces challenges in achieving predictability in heat treatment.

- 😀 Calculating the right heat treatment for food containing particles is crucial for product quality and safety.

- 😀 The challenge in processing foods like goulash soup is balancing heat treatment to preserve texture and nutrition.

- 😀 Heat treatment is a three-step process: heating the liquid, transferring heat to the particle surfaces, and reaching the particle centers.

- 😀 New research from Tetrapack helps predict how particles affect heat transfer in heat exchangers.

- 😀 By understanding the heat transfer coefficient for different particles, optimal processing can be achieved without damaging the food's texture or flavor.

- 😀 Particle size, concentration, and liquid properties are key factors in choosing the correct processing method and parameters.

- 😀 The food processing process typically takes 1 to 4 minutes, depending on the ingredients and their size.

- 😀 Product development centers use a combination of heat transfer calculations and practical trials to find the best processing solution.

- 😀 With advanced technology, food can be safely processed in a short amount of time while maintaining its quality, as seen in the goulash soup example.

Q & A

What is the main challenge in food processing when dealing with heat treatment?

-The main challenge is ensuring that heat treatment is both predictable and consistent, especially when processing foods with particles, as too much heat can destroy the texture and flavor, while too little can jeopardize food safety.

How does heat treatment work in food processing, particularly for foods containing particles?

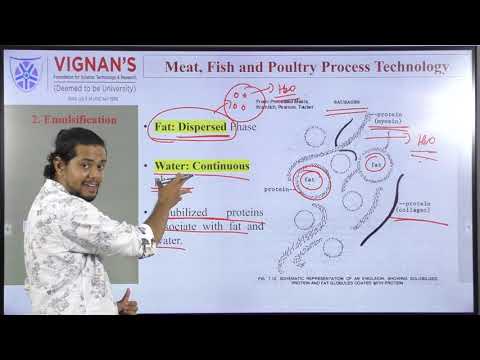

-Heat treatment in particle-containing foods is a dynamic three-step process. First, hot water heats the liquid food through the tube wall. Then, the particles' surfaces absorb heat from the surrounding liquid. Finally, heat is transferred from the surfaces to the centers of the particles.

What role does particle size and concentration play in heat treatment?

-Particle size, concentration, and the properties of the liquid are crucial factors when selecting the right heat treatment process and optimal parameters. They help determine how heat will transfer to the food and affect its texture, flavor, and safety.

What are the steps involved in calculating the right heat treatment for a food product?

-The steps include calculating the heat transfer using particle properties, considering the unique characteristics of the particles (like size and concentration), and using practical trials to adjust the process until the desired result is achieved.

What is the significance of Tetrapack’s research in heat transfer for food processing?

-Tetrapack’s research helps predict how particles affect heat transfer in heat exchangers, allowing for more accurate and optimal process designs that maintain food safety and product quality.

What is the role of the heat transfer coefficient in processing foods with particles?

-The heat transfer coefficient helps determine how efficiently heat is transferred from the liquid to the particles, which is essential for maintaining texture and flavor while ensuring food safety.

What factors influence the length of time food needs to be heated during processing?

-The heating time depends on the size of the ingredients, their journey through the process, and the specific properties of the food being processed. Typically, heating time ranges from one to four minutes.

How does the food processing industry ensure the safety and quality of a recipe like goulash soup?

-The industry ensures safety and quality by carefully designing the heating process based on the recipe's ingredients, particle properties, and the optimal heat treatment process. Practical trials and calculations are combined to find the best solution.

What is the importance of using product development centers in the food processing industry?

-Product development centers are vital for combining heat transfer calculations with practical trials, allowing food processors to fine-tune the heating process until it meets the customer’s requirements for both safety and quality.

Why is it important to preserve the texture and nutrition of food during heat treatment?

-Preserving texture and nutrition is important because it ensures that the food maintains its quality, flavor, and nutritional value after processing. Overheating can destroy these qualities, while underheating can affect food safety.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Basic Meat Processing Procedures

Understanding Quality Control, Quality Assurance, And Food Safety in The Food Industry

Materi Standar Prosedur Operasi Sanitasi

Pasteurized Egg Liquid and Powder manufacturing process PEGGS INDIA

Panduan Penerapan Good Manufacturing Practice (GMP) Sesuai SNI CXC 1:1969 Revisi 2020

The Six Steps of Steel Manufacturing

5.0 / 5 (0 votes)