3D printing with ABS: Hotter nozzle or hotter ambient? #Filaween

Summary

TLDRIn this insightful video, the speaker explores the challenges of 3D printing with ABS, particularly the critical role of layer adhesion, which suffers without a heated enclosure. They share test results showing that increasing the temperature and using an enclosure significantly improves strength, although print quality can decline. The speaker advocates for better alternatives like PET and PETG, emphasizing their reliability and ease of use. Health concerns associated with ABS fumes are also discussed, underlining the importance of safety measures. Viewers are invited to share their experiences and are encouraged to engage with the channel.

Takeaways

- 🔥 ABS filament requires an enclosed or heated build chamber to achieve optimal layer adhesion.

- 📏 Most common 3D printers do not have fully enclosed chambers, making ABS printing challenging.

- 🌡️ Increasing the print temperature to 240°C significantly improves the strength of ABS parts.

- 📦 A simple enclosure, like a shipping crate, can help maintain a suitable ambient temperature for printing ABS.

- 💨 Using a part cooling fan can slightly enhance strength but may negatively impact print quality.

- ⚖️ There is a trade-off between print quality and strength when printing with higher temperatures and enclosures.

- 📉 Different brands of ABS exhibit varied performance, with some showing more temperature-related artifacts than others.

- 🚫 Health and safety considerations suggest using an enclosure when printing ABS due to its higher particle count and fumes.

- 👍 Alternatives like copolyesters (PET and PETG) often outperform ABS in terms of printability and mechanical properties.

- 💬 Viewer engagement is encouraged, with a call for comments on personal experiences with ABS filament.

Q & A

What is the main issue with using ABS in 3D printing?

-The main issue with using ABS is that layer adhesion can significantly diminish without an actively heated build chamber or enclosure, leading to poor print quality and strength.

Why is it important to test materials under real-world conditions?

-Testing materials under real-world conditions is crucial to understand their actual performance, as most printers do not have optimal settings or enclosures that lab tests may assume.

What temperatures were tested for ABS, and what was the outcome?

-ABS was tested at 240°C, which improved strength but resulted in reduced print quality, demonstrating a trade-off between temperature and layer adhesion.

How does using an enclosure affect ABS printing?

-Using an enclosure helps maintain a warmer ambient temperature, which enhances layer adhesion and overall part strength while minimizing curling.

What alternative solutions were suggested for those unable to use a full enclosure?

-An alternative solution suggested was to cover the printer with trash bags to create a makeshift enclosure, which can help increase ambient temperature.

What were the findings regarding the impact of fan cooling on ABS prints?

-Surprisingly, adding a part cooling fan during the printing process seemed to improve strength slightly, likely due to better alignment of the layers.

What other materials benefit from an enclosed printing environment?

-Materials like ASA, HIPS, and certain PC-ABS blends also show improved performance in an enclosed environment, similar to ABS.

Why are copolyesters like PET and PETG recommended over ABS?

-Copolyesters like PET and PETG are easier to print, more consistent in performance, and have better mechanical properties, making them preferable for most applications.

What health considerations are associated with printing ABS?

-ABS emits a higher particle count when printed, which can pose health risks; therefore, using an enclosure can help mitigate exposure to fumes and particles.

Does the speaker believe ABS is a universally bad material?

-No, the speaker acknowledges that ABS has its uses but argues that for many applications, there are better and more reliable alternatives available.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

How To Succeed When 3D Printing With ABS Filament // How To 3D Print Tutorial

Which LAYER HEIGHT gives you the STRONGEST 3D prints?

3D Printers - CompTIA A+ 220-1101 - 3.7

Transparent FDM 3D Prints are Clearly Stronger!

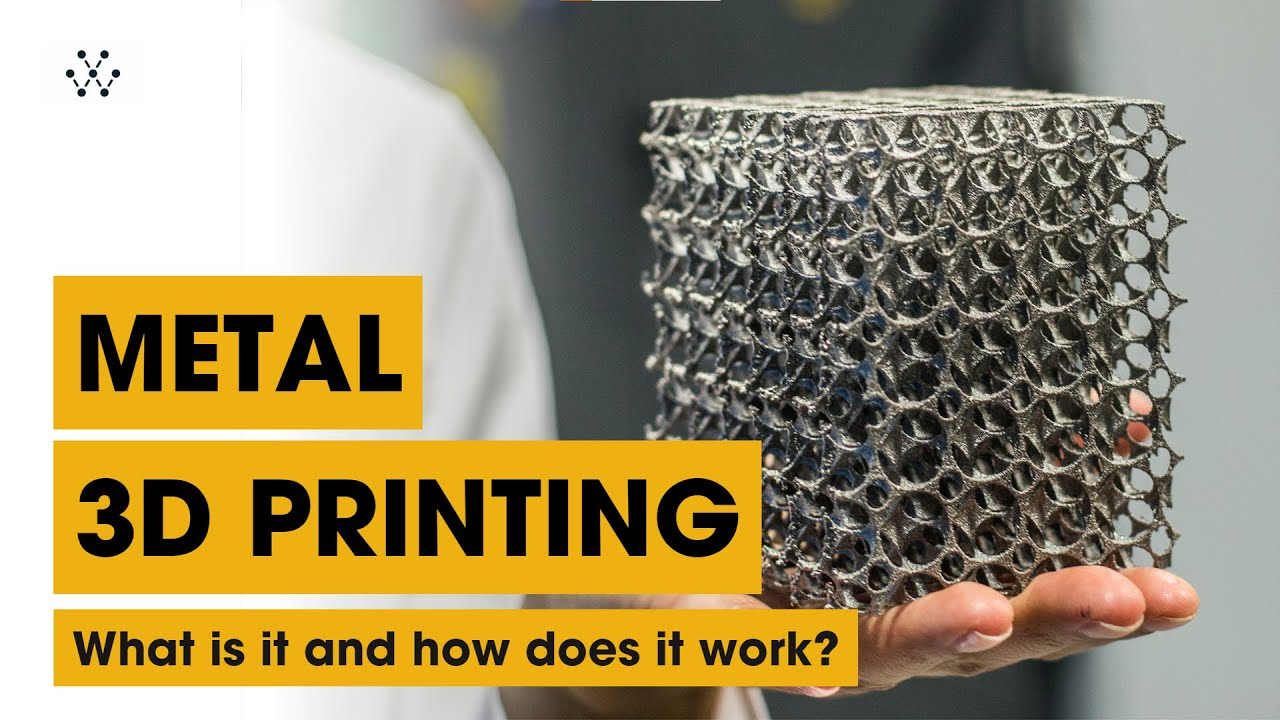

METAL 3D PRINTING | What is it and how does it work ?

Filament Oilers Revisited #1 - not as bad as I thought!

5.0 / 5 (0 votes)