Filament Oilers Revisited #1 - not as bad as I thought!

Summary

TLDRIn this CNC Kitchen video, the host revisits the impact of oiling 3D printing filament after viewer feedback. Initial tests showed that adding oil reduced layer adhesion, but new experiments revealed mixed results, with some prints showing improved strength and quality when oiled, particularly with a standard brass nozzle. The host discusses the varying effects of different oils and filaments on print performance, expressing caution about recommending oiling due to potential issues. Despite the findings, they acknowledge that filament oiling may not be as detrimental as once thought, highlighting notable improvements in print quality.

Takeaways

- 😀 The video revisits the topic of oiling 3D printer filament to assess its impact on material strength.

- 🛠️ Previous tests showed a 60% decrease in layer adhesion when using machine oil.

- 🌱 Viewers suggested using vegetable oil instead of machine oil for better results.

- 📊 New tests were conducted with varying amounts of oil on PLA filament to compare strength.

- ❓ Results were unexpected, showing oiled specimens performed better than unoiled ones.

- 🔍 The use of a tungsten nozzle introduced complications, affecting print quality.

- 🔄 Switching back to a standard brass nozzle improved print performance.

- 🤔 The study raised questions about why machine oil was detrimental compared to vegetable oil.

- 🏆 Despite mixed results, the filament oiler produced high-quality prints, including impressive benchies.

- 📣 The video concludes with an invitation for viewers to share suggestions for improvement.

Q & A

What was the initial hypothesis regarding oiling filament in 3D printing?

-The initial hypothesis suggested that oiling filament would negatively affect the material strength and layer adhesion of 3D prints.

What feedback did the presenter receive from viewers about the previous oiling experiment?

-Viewers complained that the presenter used too much oil and the wrong type of oil in the initial tests.

What types of oil were tested in the follow-up experiments?

-The follow-up experiments tested high-temperature cooking oil, as well as comparisons between oiled and unoiled prints.

What were the results of the initial tests with oil compared to prints without oil?

-The initial tests showed that the strength of specimens with oil was about 60% lower than those printed without oil.

What did the presenter discover about the tungsten nozzle used in the tests?

-The presenter noted that the tungsten nozzle had a poor surface finish and was not perfectly centered, which may have affected print quality.

How did switching back to a brass nozzle impact the test results?

-After switching back to a standard 0.4mm E3D brass nozzle, the oiled prints showed slightly improved strength compared to the previous results with the tungsten nozzle.

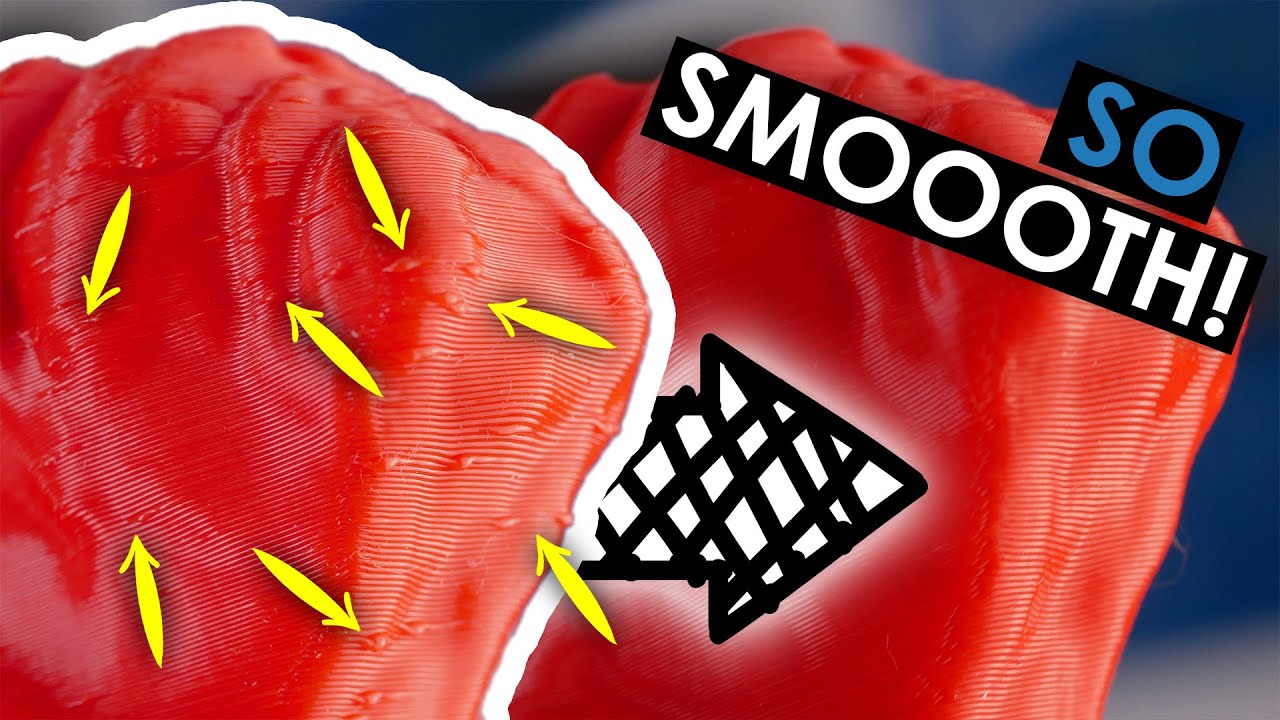

What was the impact of oiling on the quality of prints according to the presenter?

-The presenter found that oiled prints had a better surface finish and fewer artifacts, leading to some of the nicest prints achieved.

What reasons did the presenter provide for not recommending oiling filament?

-The presenter cautioned that oiling filament could lead to issues such as poor bed adhesion and inconsistent results across different filament types.

What did the presenter conclude about the overall effects of oiling filament?

-Despite some improvements in print quality, the presenter concluded that oiling filament is not as bad as initially thought but still not advisable due to potential problems.

What type of feedback does the presenter encourage from viewers?

-The presenter encourages viewers to leave comments about what could have been done differently and to provide constructive feedback on the video.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)