How to make a propeller sand mold

Summary

TLDRIn this video, the intricate process of casting a bronze propeller is demonstrated, highlighting key steps such as cleaning, molding, and packing sand. The process involves careful preparation, including applying talcum powder to prevent mold sticking, packing sand around the propeller, and marking precise lines for accurate casting. The sprew and riser are positioned to guide the molten bronze, while the mold is meticulously handled to ensure minimal damage. Finally, after pouring the bronze, the propeller is revealed, requiring further grinding to perfect its shape. This detailed guide offers insight into the craftsmanship behind creating a bronze propeller.

Takeaways

- 😀 Start by cleaning and preparing the propeller to ensure it can easily be removed from the mold later.

- 😀 Apply talcum powder to areas where the mold may stick to help with smoother separation.

- 😀 Use cardboard to cover the hole in the mold box and prevent sand from falling in while packing the mold.

- 😀 Sift and pack layers of sand over the propeller, making sure to pack sand underneath the propeller blades for stability.

- 😀 After packing the sand, carefully scrape off the top layer to ensure it’s smooth and even before rolling the mold over.

- 😀 Mark the center line on the mold for accuracy, and then dust the center hole with talcum powder for easier mold separation.

- 😀 Fill the mold box with more sand, ensuring it’s packed full and the mold is stable.

- 😀 Trim parting lines carefully, and dust these lines with talcum powder to ensure the mold separates easily after casting.

- 😀 Position the sprue and riser in the mold before adding the top layer of sand to ensure proper metal flow during casting.

- 😀 Once the mold is ready, lift the top box and prepare the furnace filled with molten bronze ingots for pouring.

- 😀 After the molten bronze is poured and cooled, remove the propeller from the mold, grind off any rough edges, and finalize the product.

Q & A

What is the main purpose of the video?

-The video demonstrates the process of creating a bronze propeller mold through casting.

Why is it important to clean the propeller before molding?

-Cleaning the propeller is essential to ensure that it can be removed easily from the mold and that the final casting is smooth and accurate.

What role does talcum powder play in the process?

-Talcum powder is used to help the mold release more easily from the propeller, preventing it from sticking.

How is sand prepared for the mold?

-The sand is sifted and packed tightly under the propeller blade to create a stable and supportive mold.

What are parting lines, and why are they significant?

-Parting lines are the seams where the two halves of the mold meet. They are crucial for ensuring the mold can be opened and closed correctly without damaging the cast piece.

What is the importance of dusting the mold with 'T' powder?

-Dusting with 'T' powder ensures that the mold separates cleanly at the parting lines, reducing the risk of damage to the mold and the final piece.

What are the challenges faced while withdrawing the pattern from the mold?

-Care must be taken to withdraw the pattern without damaging the mold, as rough handling can lead to imperfections in the final casting.

What precautions are mentioned regarding the sprew?

-It is important to carefully cut the sprew to avoid damaging the mold during the removal process.

What materials are used for the casting in this video?

-Bronze ingots are used as the material for casting the propeller.

What does the video conclude with regarding the bronze propeller mold?

-The video concludes with the completed bronze propeller mold being ready for pouring, showcasing the successful preparation and molding process.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Materiais e Processos de Fabricação para Engenharia de Produção - Fundição - Conceito, etapas e...

Proses Tuangan Logam Sand Casting Part 1

Sand Casting

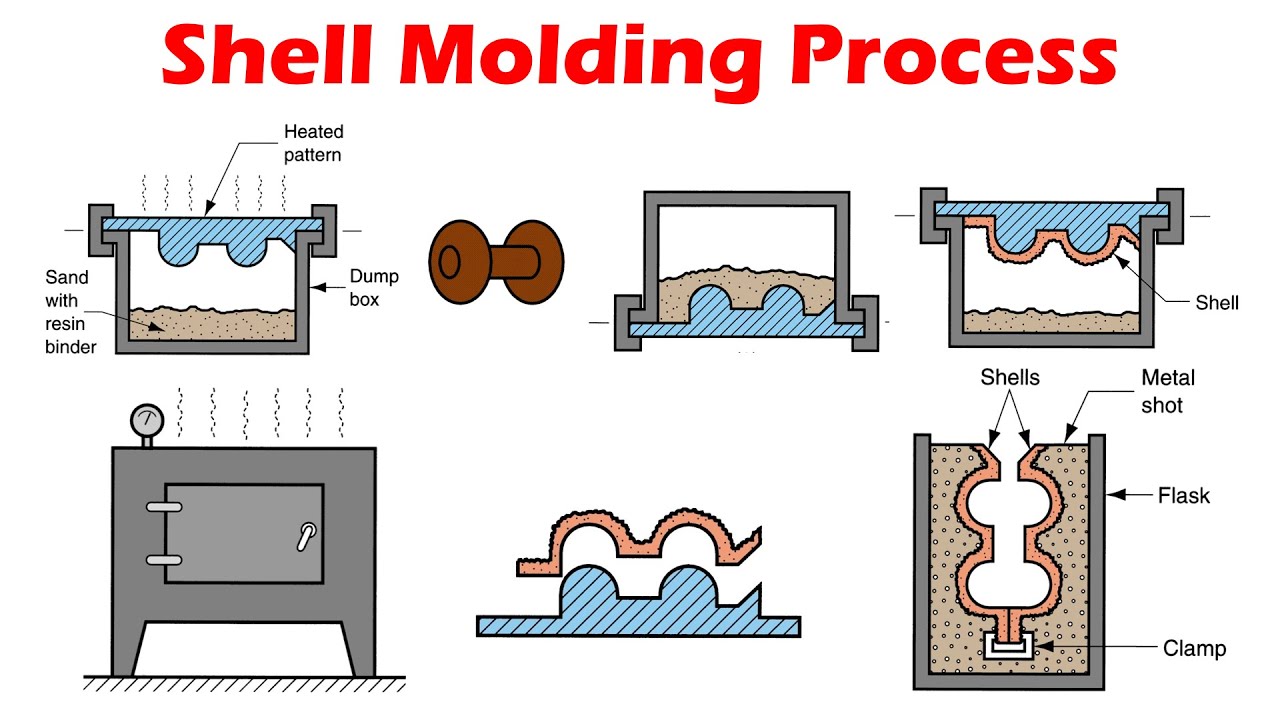

Shell Molding - Expandable Mold Casting Processes

Amazing Process Of Making High Quality Bronze Bowls. Korean metal foundry

Ekonomis!!! Cara membuat paving blok dari sampah plastik

5.0 / 5 (0 votes)