#Centrifugical pumps troubleshooting

Summary

TLDRThis video script provides essential guidelines for ensuring the reliability and longevity of centrifugal pumps. It highlights the importance of three key practices: keeping pumps clean, properly lubricated, and aligned. The script covers common maintenance tasks such as replacing mechanical seals, servicing packed pumps, and ensuring proper startup and shutdown procedures. It also emphasizes the need for regular checks on pump performance, bearing temperature, and lubrication to prevent failures. By following these practices, operators can significantly reduce the likelihood of pump problems and extend their service life.

Takeaways

- 😀 Keep it clean: Cleanliness is crucial for pump reliability, especially when handling seals and during servicing.

- 😀 Keep it lubed: Proper lubrication of the pump's moving parts, including seals, bearings, and shaft, is essential to prevent failure.

- 😀 Keep it aligned: Ensure proper pump alignment with the driver to avoid unnecessary wear and tear and maximize efficiency.

- 😀 Always follow manufacturer instructions: Specific pump models have distinct maintenance and servicing requirements, so always check the guidelines.

- 😀 Use lockout procedures: Prioritize safety by ensuring the pump is locked out to prevent accidental startup during maintenance.

- 😀 Cleanliness before sealing: Dirty hands and surfaces can damage seals, so ensure everything is clean during the sealing process.

- 😀 Seal condition matters: Inspect mechanical seals for warping or damage before installation, as even a small defect can cause failure.

- 😀 Repack carefully: When replacing pump packing, remove all old packing, inspect the shaft for damage, and follow the manufacturer's instructions for proper installation.

- 😀 Priming is essential: Before starting a pump, ensure it is fully primed to avoid cavitation and potential damage to the pump.

- 😀 Monitor pump performance: Regularly check key parameters like leakage, lubrication, bearing temperature, and pump flow to identify early signs of trouble.

Q & A

Why do some centrifugal pumps last forever while others fail frequently?

-Pump failures can be due to various factors such as handling inappropriate fluids, contamination, lack of proper lubrication, or misalignment. The reliability of a pump depends on the conditions it operates under, maintenance practices, and the type of fluids it handles.

What are the three key practices for preventing pump failure?

-The three key practices are: keep it clean, keep it lubed, and keep it aligned. Proper cleanliness, adequate lubrication, and correct alignment can prevent most pump failures.

Why is cleanliness important when servicing a pump?

-Cleanliness is crucial because contamination, like dirt or debris on seals or parts, can cause damage and lead to premature failure. It's important to handle parts with clean hands and ensure the working area is free of dirt.

What is the role of lubrication in pump operation?

-Lubrication is essential for preventing wear and ensuring smooth operation of moving parts like bearings and seals. It also plays a critical role in maintaining the correct seal pressure and the leakage rate in packed pumps.

What should be done before replacing a leaking mechanical seal?

-Before replacing a mechanical seal, ensure the pump is properly shut down using lockout/tagout procedures, especially for hazardous fluids. You should also clean the inside of the pump, inspect the shaft for burrs or damage, and check that you have the correct seal for replacement.

What is the importance of alignment in pump maintenance?

-Alignment is crucial to ensure the pump and its driver work together efficiently. Misalignment can lead to excessive wear, vibration, and even pump failure. Proper alignment is especially important for maintaining long-term pump performance.

Why should the suction valve be fully open before starting a pump?

-The suction valve must be fully open before starting the pump to ensure the pump receives proper fluid intake. A restricted suction flow could lead to overheating, cavitation, or damage to the pump components.

How can pump cavitation be prevented?

-To prevent cavitation, ensure the pump is properly primed and avoid restricting the suction flow. If air or gases enter the system, they can create cavitation, which can damage the pump parts. Maintaining the correct pressure and fluid flow is crucial.

What should be checked during a pump's initial startup?

-During startup, it is important to ensure the pump is properly lubricated, primed, and the discharge is opened according to the manufacturer's instructions. After startup, monitor the discharge gauge to verify fluid flow and ensure the pump is not losing prime.

Why is it important to monitor the pump's operating conditions regularly?

-Monitoring the pump's operating conditions such as bearing temperature, pressure, and flow helps identify potential issues before they lead to failure. Regular checks can extend the pump's lifespan and help with early detection of problems, reducing downtime.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифПосмотреть больше похожих видео

Tertarik tentang Mechanical ?? Yuk pelajari Dasar-Dasar Mechanical

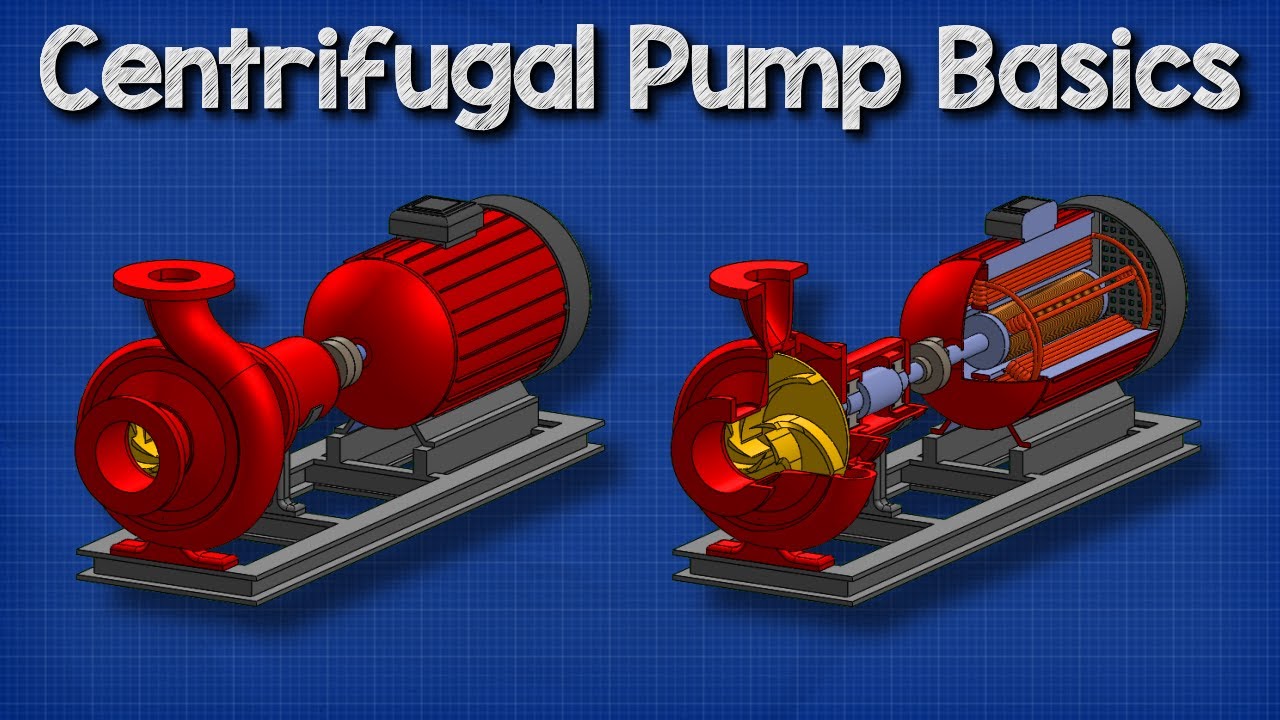

Centrifugal Pump Basics - How centrifugal pumps work working principle hvacr

Centrifugal Pump Basics I Definition I Working I Velocity Triangle I Work Done I Head I Efficiency

Types of pump | Working methods

Types of Pumps | All in One Guide to Industrial Pump Types

POMPA | Definisi Pompa | Jenis-jenis Pompa

5.0 / 5 (0 votes)