POMPA | Definisi Pompa | Jenis-jenis Pompa

Summary

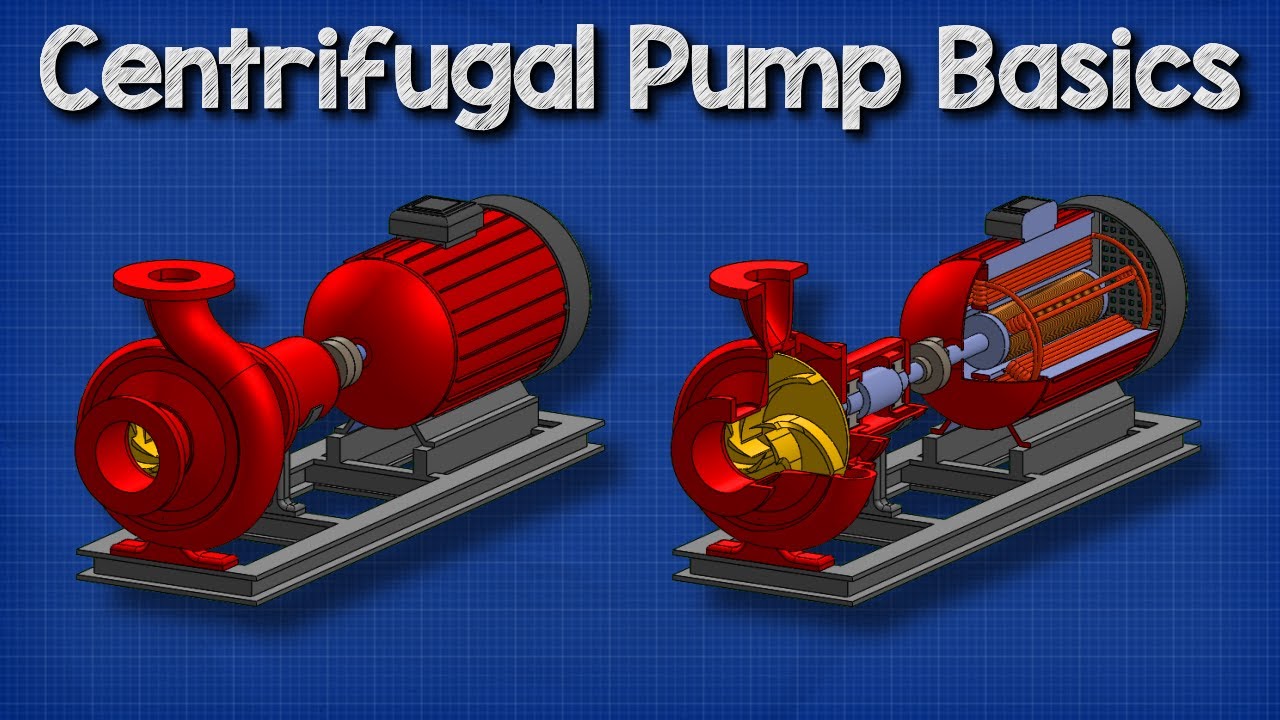

TLDRIn this video, the speaker introduces the concept of centrifugal pumps, explaining their function in moving fluids from low-pressure areas to high-pressure ones. They discuss different types of pumps, such as centrifugal and positive displacement pumps, and highlight their uses in industrial applications. The video delves into the components of centrifugal pumps, including the impeller, shaft, bearing, and casing, detailing their roles in maintaining efficient fluid flow. The speaker concludes with a brief preview of upcoming content on pump calculations and selection processes, encouraging viewers to subscribe and share the video for broader reach.

Takeaways

- 😀 Pumping systems are used to move fluids from one location to another, typically from low pressure to high pressure areas.

- 😀 Pumps provide energy to fluids, enabling them to overcome obstacles such as pipe friction, valves, or variations in height.

- 😀 Two main types of pumps in industrial settings: centrifugal pumps and positive displacement pumps.

- 😀 Centrifugal pumps are used for low head (pressure) flows, while positive displacement pumps handle high head or high-viscosity flows.

- 😀 A centrifugal pump uses a rotating impeller to create a vacuum that draws fluid into the pump and moves it to the discharge point.

- 😀 Centrifugal pumps can be classified into three types based on flow pattern: axial flow, radial flow, and mixed flow.

- 😀 Axial flow pumps have a 90° angle between the inlet and outlet, radial flow pumps have a 180° angle, and mixed flow pumps have a 45° angle.

- 😀 The key components of a centrifugal pump include the rotating impeller, shaft, bearings, and casing.

- 😀 The impeller converts mechanical energy into velocity energy in the fluid, ensuring continuous flow and preventing fluid cavitation.

- 😀 Casing protects the internal components and directs the fluid flow from the suction nozzle through the impeller and out through the discharge nozzle.

- 😀 The wear ring components reduce leakage between the casing and impeller, minimizing the potential for fluid loss during operation.

Q & A

What is the primary function of a pump?

-A pump is a device or machine used to move fluids from one place to another, typically from an area of low pressure to high pressure. It provides the energy needed to overcome obstacles such as friction or differences in elevation.

What are the two general types of pumps mentioned in the script?

-The two general types of pumps mentioned are centrifugal pumps and positive displacement pumps. Centrifugal pumps are typically used for low-pressure flows, while positive displacement pumps are used for high-pressure flows or flows with high viscosity.

How does a centrifugal pump work?

-A centrifugal pump uses an impeller that continuously rotates, creating a vacuum that draws fluid into the suction line. The impeller then propels the fluid out through the discharge line with increased pressure, allowing it to move to another location.

What are the three types of centrifugal pumps based on flow direction?

-The three types of centrifugal pumps based on flow direction are axial flow pumps, radial flow pumps, and mixed flow pumps. Axial flow pumps have a 90° angle between the inlet and discharge lines, radial flow pumps have a 180° angle, and mixed flow pumps usually have an angle of 45°.

What is the role of the impeller in a centrifugal pump?

-The impeller in a centrifugal pump transforms mechanical energy into velocity energy in the fluid, causing the fluid to flow continuously. It ensures that the suction line works effectively by keeping the fluid flowing and preventing air pockets within the pump casing.

What is the function of the shaft sleeve in a centrifugal pump?

-The shaft sleeve in a centrifugal pump protects the shaft from erosion, corrosion, and wear that may result from the rotating motion of the shaft. It helps maintain the integrity of the shaft, preventing damage during operation.

What is the purpose of the wearing components in a centrifugal pump?

-Wearing components, such as the casing wear and impeller wear rings, are used to minimize leakage caused by gaps between the casing and the impeller. These components help ensure that the pump operates efficiently by preventing fluid from escaping through these gaps.

What is the casing's role in a centrifugal pump?

-The casing of a centrifugal pump is the outer shell that protects internal components. It houses parts like the diffuser, inlet nozzle, outlet nozzle, and directs the flow of fluid from the impeller to the discharge nozzle. It also converts velocity energy into pressure energy.

What are the differences between centrifugal and positive displacement pumps?

-Centrifugal pumps are designed for low-pressure flows and work by using rotational energy to move the fluid. Positive displacement pumps are suited for high-pressure applications and are used when the fluid has high viscosity, providing a steady flow regardless of pressure changes.

What will be discussed in the next video?

-The next video will likely cover the calculations for pump selection and how to choose the right pump for a given application.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Types of Pumps | All in One Guide to Industrial Pump Types

Centrifugal Pump Basics - How centrifugal pumps work working principle hvacr

Centrifugal Pump Hindi | Centrifugal Pump parts and Working

Tertarik tentang Mechanical ?? Yuk pelajari Dasar-Dasar Mechanical

Pumps Types - Types of Pump - Classification of Pumps - Different Types of Pump

Mengenal Jenis Pompa : Centrifugal Pump

5.0 / 5 (0 votes)