noc19-ee65-lec36

Summary

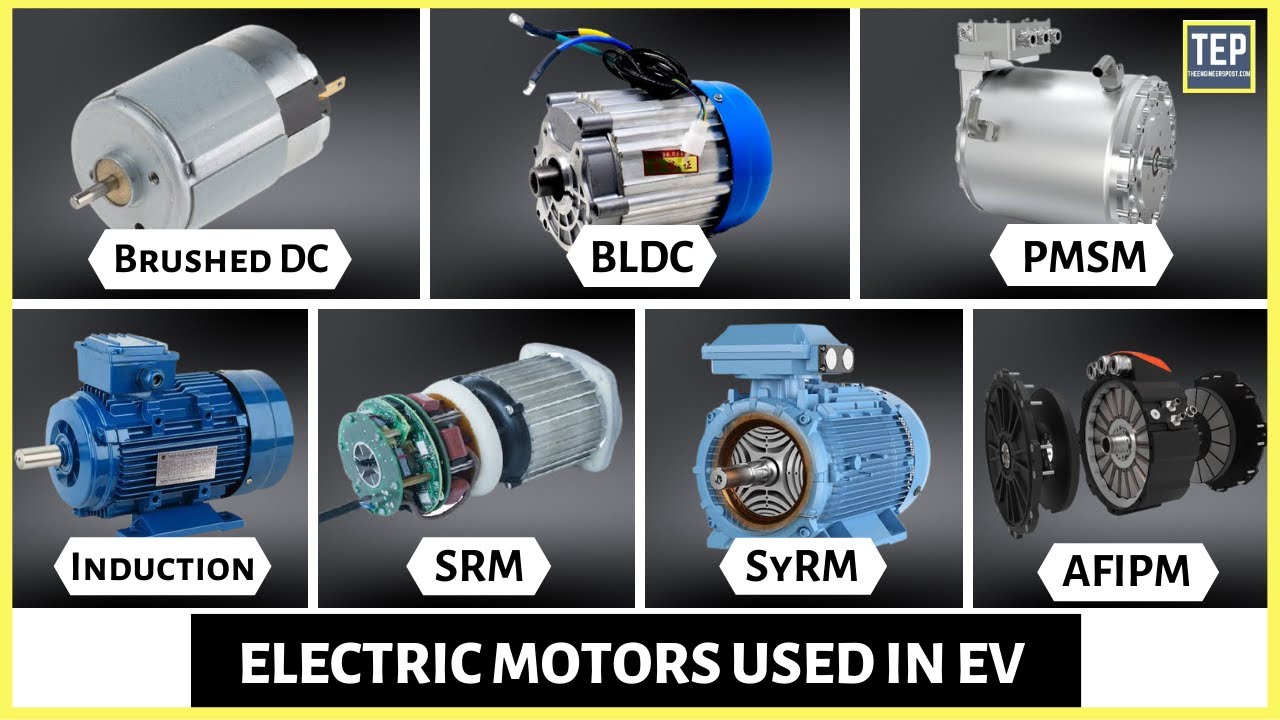

TLDRThis lecture covers the fundamentals of electric drives, focusing on trapezoidal Brushless DC (BLDC) motors and switched reluctance motors (SRMs). The BLDC motor is explained in terms of induced EMF, current waveforms, power and torque equations, and its closed-loop control system. Key benefits include reduced torque ripple, making it ideal for electric vehicles. The SRM operates based on inductance variation with rotor position, offering a simple yet reliable design used in specialized applications. The lecture also compares the two motor types, highlighting their efficiency, torque control, and practical applications in various fields.

Takeaways

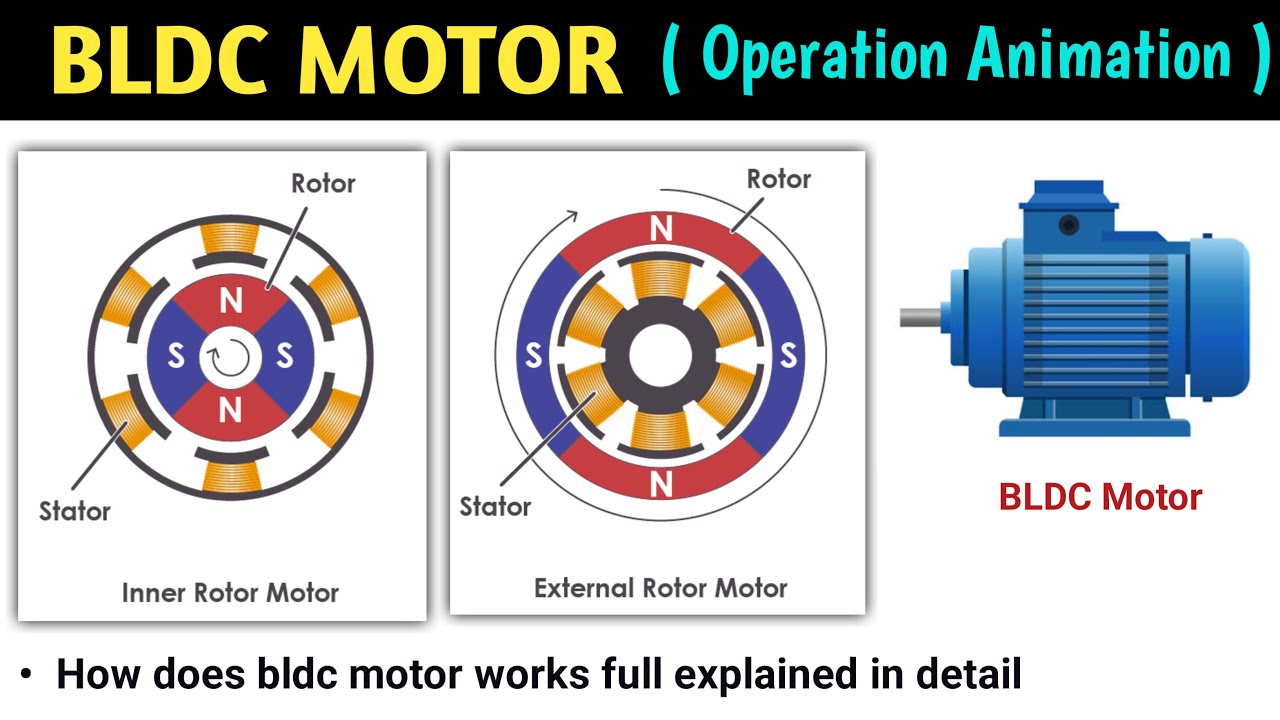

- 😀 Trapezoidally excited permanent magnet AC motors have trapezoidal back EMFs in their phases (A, B, and C), and the rotor has a two-pole structure with a north and south pole.

- 😀 The current in each phase (A, B, and C) of a trapezoidal BLDC motor is quasi-rectangular and varies with the induced EMF of each phase.

- 😀 The three-phase inverter uses a DC supply to provide quasi-rectangular currents to the stator windings of the motor.

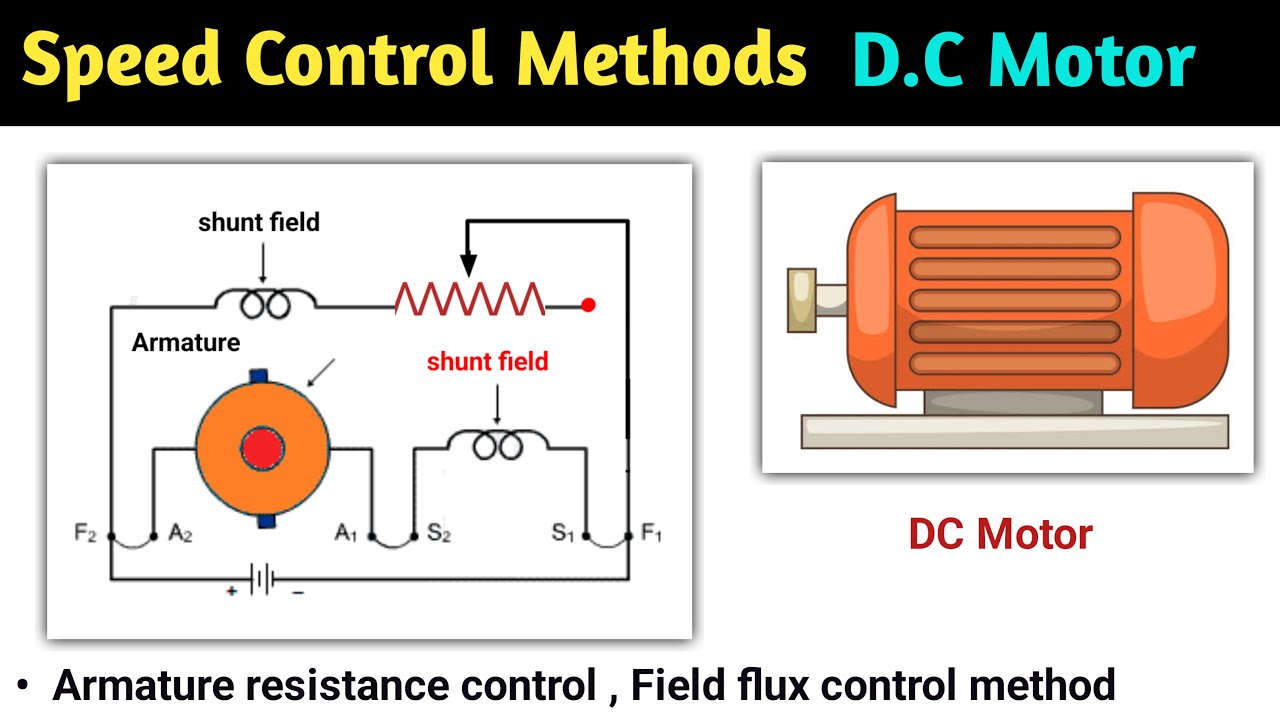

- 😀 The mechanical power of the motor is determined by the DC current (Id) in the windings, which is proportional to the torque.

- 😀 The torque equation for a BLDC motor is: Torque = 2K * Id, where Id is the current in the stator windings.

- 😀 The torque produced by a trapezoidal BLDC motor remains constant when Id is constant, resulting in minimal torque ripple, a key advantage for electric vehicle applications.

- 😀 In closed-loop control, the actual motor speed is compared with the reference speed, and the error is used to adjust the reference current (Id) via a PI controller.

- 😀 The current Id is controlled using hysteresis current control to optimize torque production in the motor.

- 😀 The motor can be controlled in a closed loop, requiring a position sensor for feedback, which ensures accurate current and torque control.

- 😀 Switched reluctance motors (SRM) have no rotor windings, and their torque is determined by the derivative of the inductance with respect to rotor position, maximizing torque during positive dL/dtheta.

Q & A

What is the primary characteristic of the induced EMF in a trapezoidal BLDC motor?

-The induced EMFs in the phases of a trapezoidal BLDC motor (phases A, B, and C) are trapezoidal in shape. This characteristic is a key feature of the motor's design.

How do the current waveforms in the trapezoidal BLDC motor relate to the induced EMF?

-The current waveforms in phases A, B, and C of the trapezoidal BLDC motor are quasi-rectangular in nature, and their polarity (positive or negative) matches the polarity of the induced EMFs in each phase.

What role does the inverter play in a trapezoidal BLDC motor system?

-The inverter in a trapezoidal BLDC motor system is used to convert DC power into the quasi-square AC currents that are fed into the stator windings. It controls the current in each phase according to the induced EMFs.

What is the relationship between the current (Id) and the torque produced by the BLDC motor?

-The torque in the trapezoidal BLDC motor is directly proportional to the current Id. Increasing Id results in higher torque, while decreasing Id reduces the torque.

Why is the trapezoidal BLDC motor considered advantageous for electric vehicle applications?

-The trapezoidal BLDC motor is advantageous for electric vehicles due to its low torque ripple, which leads to smoother operation and reduced mechanical stress. This makes it ideal for cost-effective and efficient applications like electric scooters and vehicles.

What are the key components in the closed-loop control system for a trapezoidal BLDC motor?

-In the closed-loop control system, key components include a speed controller (usually a PI controller), a current limiter, a hysteresis current control mechanism, and a position sensor to provide feedback for rotor position and speed regulation.

How does the speed control system for a trapezoidal BLDC motor work?

-The speed control system works by comparing the reference speed with the actual speed of the motor. The error is passed to a PI controller, which determines the reference current (Id). This reference current is used to adjust the current in the stator windings via hysteresis current control, optimizing torque and speed.

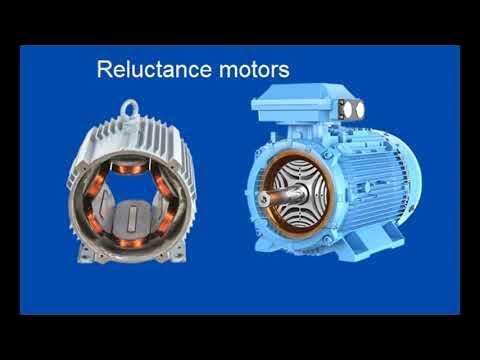

What is the primary principle behind the operation of a switched reluctance motor (SRM)?

-The primary principle behind the operation of an SRM is the variation in inductance as the rotor moves. The torque is generated by the derivative of inductance with respect to rotor position (dL/dθ). Current is supplied to the stator winding only when this derivative is positive to optimize torque.

What are the key constructional features of a switched reluctance motor (SRM)?

-A switched reluctance motor has a stator with multiple poles (in this case, 8 poles) and a rotor with fewer poles (6 poles). The rotor does not have windings, while the stator poles have windings that generate the magnetic field.

What are the main applications of switched reluctance motors (SRMs)?

-Switched reluctance motors are mainly used in high-performance applications that require robustness and lightweight designs, such as in space applications and other environments where weight and efficiency are critical.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード関連動画をさらに表示

bldc motor | brushless dc motor | brushless dc motor construction and working | brushless motor

Reluctance motors explained

PID control of BLDC motor

Brushless DC Motor, How it works ?

Types of Motors used in EV | Single, Dual, Three & Four Motor Configuration in EV

speed control of dc motor | speed control of dc shunt motor | dc motor speed control | series motor

5.0 / 5 (0 votes)