Capacity Planning - Overview and Key Concepts

Summary

TLDRThis video script delves into capacity management, defining it as the maximum output rate of a processor or system. It explores real-life applications, such as concert halls and restaurants, and distinguishes between design capacity, effective capacity, and actual production. The script discusses the importance of capacity utilization and efficiency, which are crucial for operations directors. It outlines strategies for capacity planning, including expansionist and conservative approaches, and categorizes capacity planning into short-term, medium-term, and long-term, each with its own set of drivers and considerations.

Takeaways

- 📏 Capacity management is crucial for determining the maximum output rate of a processor or system.

- 🏢 System capacity is a concept applicable to everyday life, such as planning for the number of people a concert hall or restaurant can accommodate.

- 🛠️ Design capacity refers to the theoretical maximum output under ideal conditions within a given period.

- 🔧 Project engineers design machines with a specific output rate in mind, such as producing 200 parts per minute.

- 🔄 Effective capacity is the output expected by a company under current operational constraints, which can differ from the design due to factors like product mix.

- 🔄 Capacity available can be influenced by changes in work content, product mix, or the speed of operations.

- 📈 Measuring utilization and efficiency helps in understanding how well a system is performing against its design capacity.

- 📈 Efficiency is calculated as real production divided by effective capacity, and it's a key metric for operations directors.

- 📈 Capacity strategy involves deciding whether to add capacity ahead of demand (expansionist) or to wait and see (conservative).

- 📈 Different time horizons for capacity planning include short-term (0-3 months), medium-term (3-12 months), and long-term (1-5 years), each with different drivers and strategies.

- 🔩 In short-term capacity planning, options like overtime work can be considered to meet immediate demands.

Q & A

What is the definition of capacity management?

-Capacity management refers to the maximum rate of output of a processor or system, which is the theoretical maximum output in a given period under ideal conditions.

How does capacity management apply to everyday life?

-In daily life, capacity management is seen in determining how many people a concert hall or a restaurant should accommodate, or how many batteries a plant should be able to produce.

What is the role of a Project Engineer in capacity management?

-A Project Engineer is responsible for designing machines to run at a certain output rate, such as 200 parts per minute, which is the design capacity.

What is the difference between design capacity and effective capacity?

-Design capacity is the theoretical maximum output under ideal conditions, while effective capacity is the output expected by the company under current operations constraints.

How can changes in work content, product mix, or equipment affect capacity available?

-Changes in work content, product mix, or equipment can affect capacity available by altering the speed or pace at which work is done, thus impacting the efficiency and output of the system.

What is the formula for measuring utilization in capacity management?

-Utilization is measured by the formula: real production / design capacity.

What is the formula for calculating efficiency in capacity management?

-Efficiency is calculated by the formula: real production / effective capacity.

Why is efficiency important for an operations director?

-Efficiency is crucial as it is the main driver for the operations director, helping to determine the effectiveness of the operations and the need for capacity adjustments.

What are the two main capacity strategies mentioned in the script?

-The two main capacity strategies are 'add capacity to go ahead of demand', which is an expansionist strategy, and 'wait and see', which is a conservative strategy.

What are the main drivers for short-term capacity management?

-The main drivers for short-term capacity management are planning jobs, planning people, and scheduling machines.

What are the main drivers for medium-term and long-term capacity planning?

-For medium-term capacity planning, the main drivers are subcontract operations, adding manpower, increasing or using stocks, adding shifts, and adding equipment. For long-term capacity planning, the main driver is adding installations at equipment with long installation lead times.

How can overtime work be a part of short-term capacity planning?

-Overtime work can be a part of short-term capacity planning as it allows for an increase in production output within a short period, typically up to 3 months.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード関連動画をさらに表示

Capacity Management (No Background Music)

CAPACITY MANAGEMENT - Learn and Gain

Liane Okdinawati: Strategic Capacity (Part 1)

Carrying Capacity simple explanation | Ecological Carrying Capacity

What is Capacity Management in Business Operations?

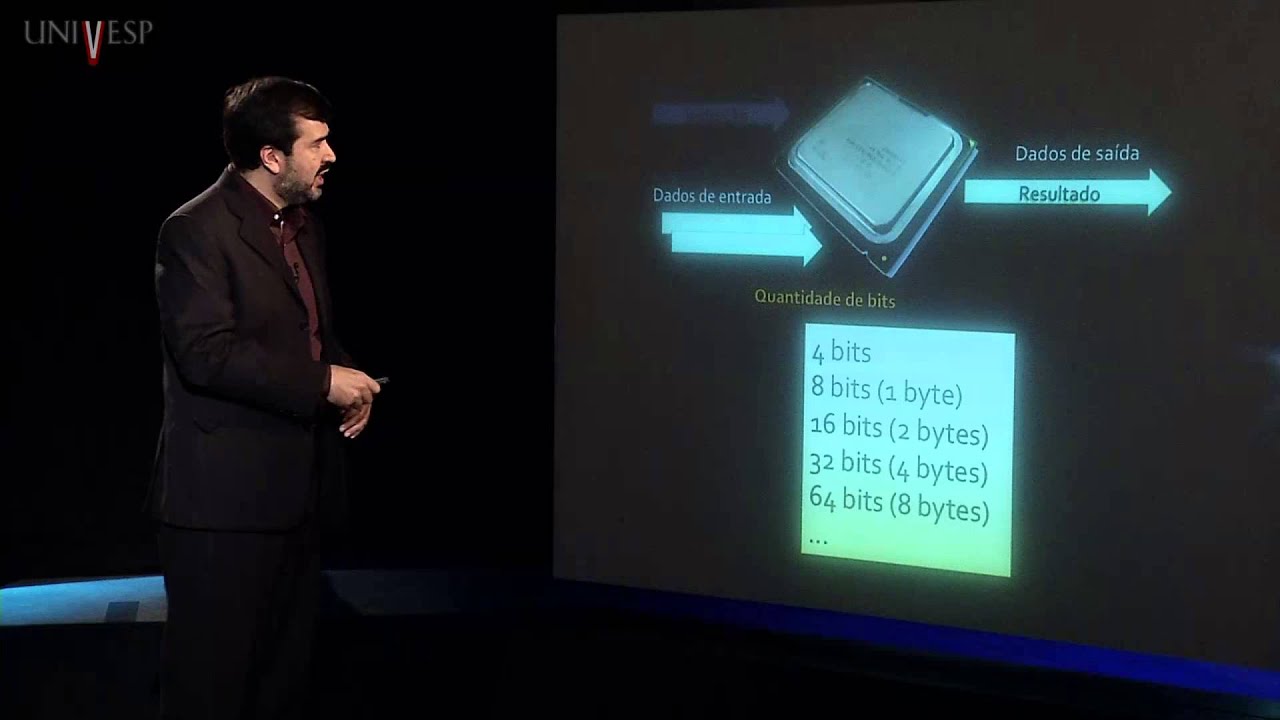

Informática Aula 2 - Elementos da organização de computadores

5.0 / 5 (0 votes)